A kind of surface cadmium-rich cdse quantum dot photocatalyst and its preparation method and application

A photocatalyst and quantum dot technology, applied in the field of nanomaterials, can solve the problems of low catalytic activity and poor stability, and achieve the effects of promoting electron conduction, solving low efficiency, excellent activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

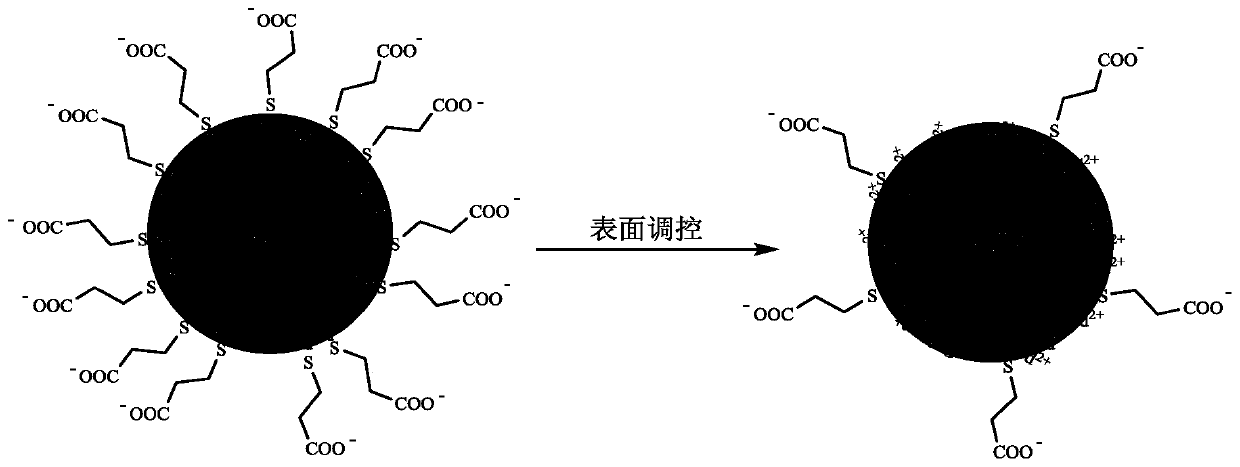

[0033] Embodiment 1-4: CdSe quantum dot with high catalytic activity and its preparation method. The schematic flow chart of the preparation method is as figure 1 As shown, after adjusting the pH of the CdSe quantum dot solution modified with ligands on the surface, the ligands modified on the surface of the CdSe quantum dots react with hydrogen ions, so that at least part of the ligands are stripped from the surface of the CdSe quantum dots. After stripping the surface ligands by acid make the surface Cd 2+ Barely obtained CdSe quantum dots with high catalytic activity. The surface cadmium and selenium contents corresponding to the prepared CdSe quantum dots were obtained by X-ray photoelectron spectroscopy (XPS), as shown in Table 1.

[0034] Table 1

[0035]

Embodiment 1

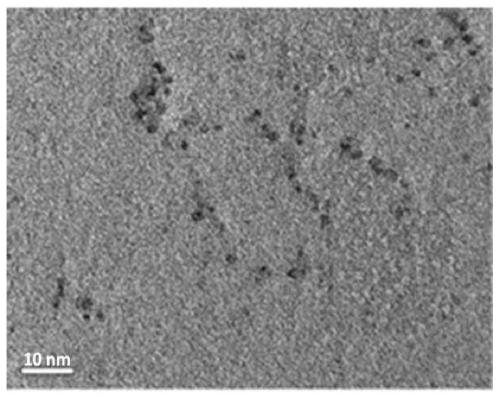

[0037] CdCl 2 2.5H 2 O (46.0 mg, 0.2 mmol) was dissolved in deionized water (190.0 mL), stirred, 3-mercaptopropionic acid (MPA, 26.0 μL, 0.3 mmol) was added, and 1.0 mol / L NaOH solution was added dropwise to the solution to adjust the pH to 11. Charge N 2 Add 5.0mmol / L Na after protection 2 SeSO 3 The solution (20 mL, 0.1 mmol) was heated to 120° C. for 4 hours. After cooling, the solution was concentrated to 40.0 mL, and 36% concentrated hydrochloric acid was added thereto to adjust the pH to 3. Solids were precipitated, centrifuged, washed, and dried to obtain a yellow solid. The obtained solid is tested by TEM, showing that its particle size is about 2nm, such as figure 2 shown.

Embodiment 2

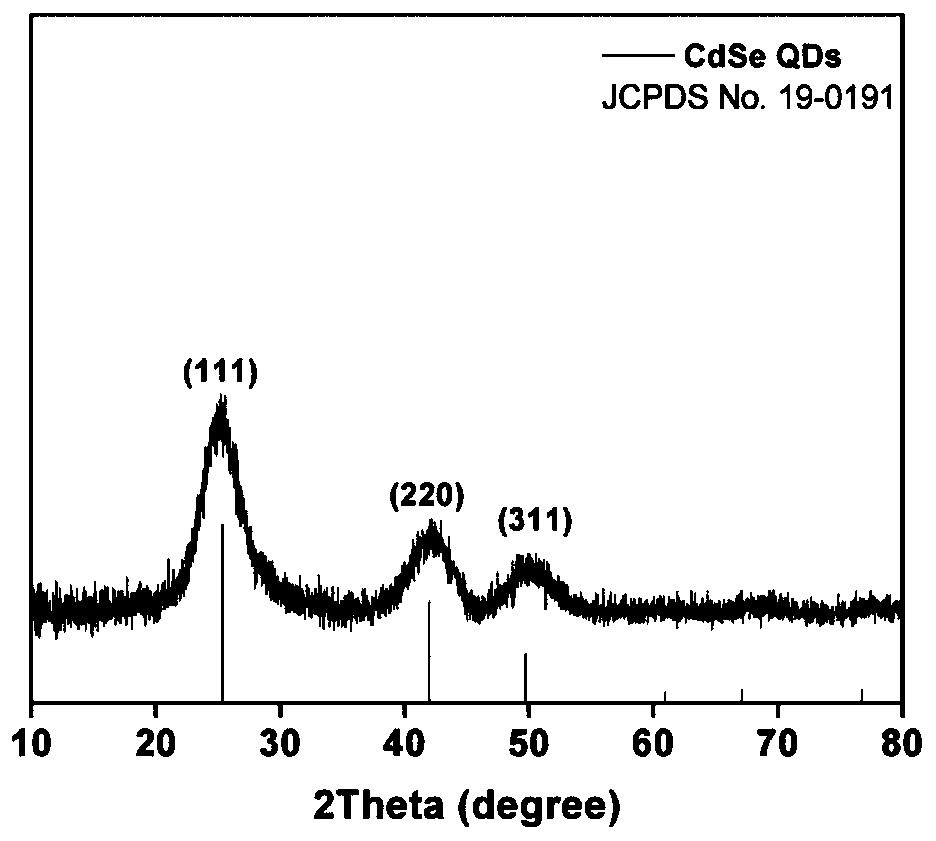

[0039] CdCl 2 2.5H 2 O (46.0 mg, 0.2 mmol) was dissolved in deionized water (190.0 mL), stirred, 3-mercaptopropionic acid (MPA, 26.0 μL, 0.3 mmol) was added, and 1.0 mol / L NaOH solution was added dropwise to the solution to adjust the pH to 10, charge N 2 Add 5.0mmol / L Na after protection 2 SeSO 3 solution (10.0 mL, 0.05 mmol), heated to 130° C. for 3 hours. After cooling, the solution was concentrated to 40.0 mL, and 37% concentrated hydrochloric acid was added thereto to adjust the pH to 3. Solids were precipitated, centrifuged, washed, and dried to obtain a yellow solid. The X-ray diffraction (XRD) pattern of the prepared quantum dots is shown as image 3 As shown, corresponding to (111), (220), (311) crystal planes respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com