Welding automatic moving device of automobile door frame

A technology of automatic movement and door frame, which is applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., to achieve the effect of high degree of automation, improved equipment stability, and convenient adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

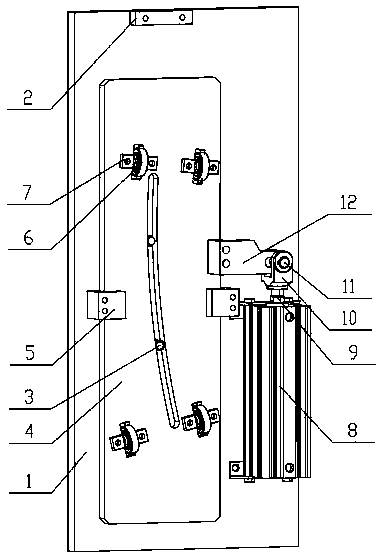

[0008] The specific implementation is as follows: the moving plate limit block 2 is installed on the base plate 1, the support pulley bearing 3 is installed on the base plate 1, the moving plate 4 is installed on the support pulley bearing 3, the limit plate 5 is installed on the base plate 1, and the ball bearing 6 is installed on the bearing shaft 7, the bearing shaft 7 is installed on the moving plate 4, the jacking cylinder 8 is installed on the bottom plate 1, the piston rod 9 is installed on the jacking cylinder 8, the connecting joint 10 is installed on the piston rod 9, and the pin 11 is installed on the connection block 12, and the connection block 12 is installed on the moving plate 4 so that the moving arc of the moving plate 4 is consistent with the product welding arc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com