Automatic hardware polishing machine and using method thereof

A technology of polishing machine and polishing mechanism, which is applied in the direction of surface polishing machine tools, grinding/polishing equipment, grinding feed movement, etc., can solve the problems of reducing product processing efficiency, prolonging processing cycle, increasing processing cost, etc., to achieve The effect of shortening the production cycle, improving the waxing effect and improving the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

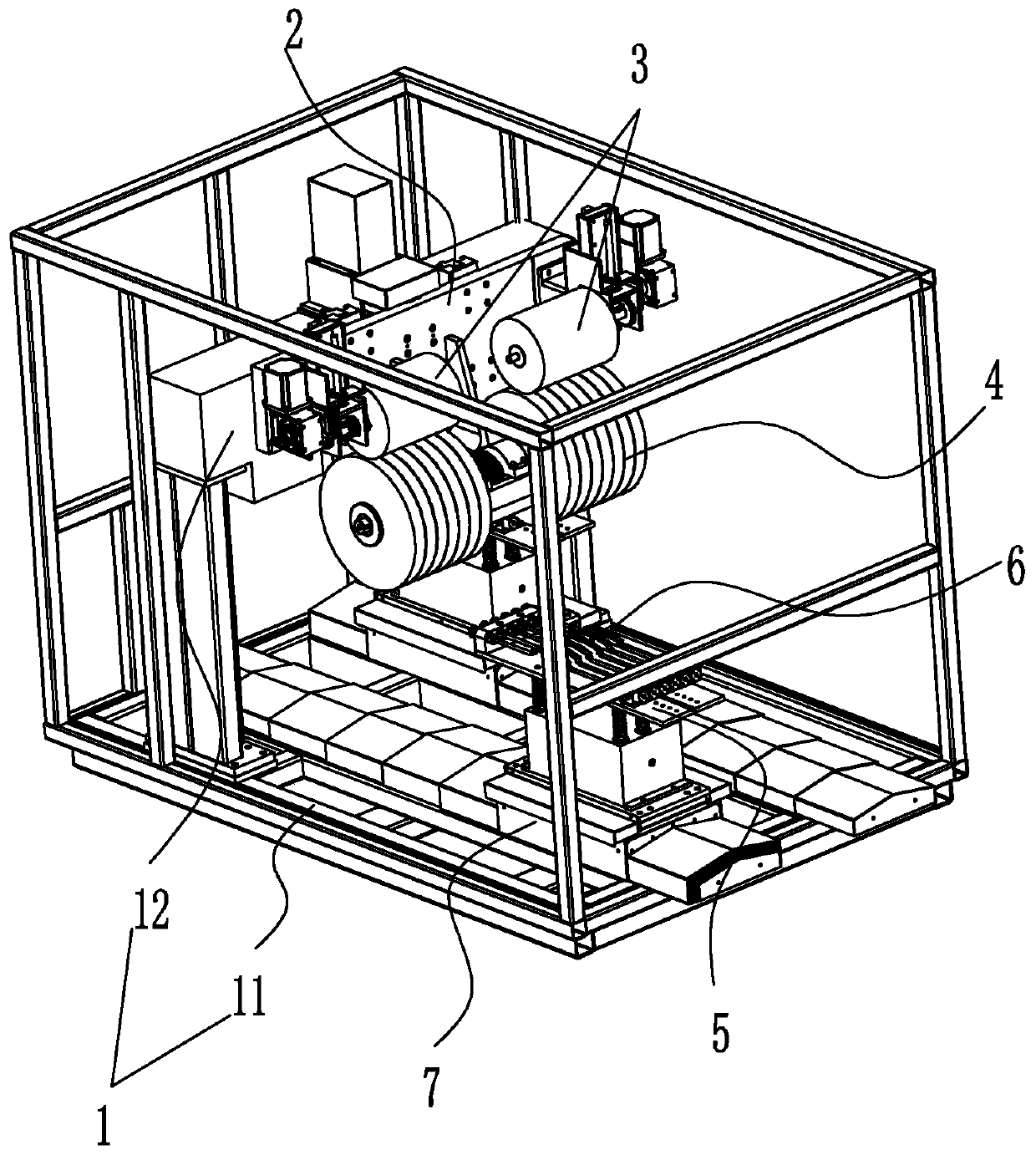

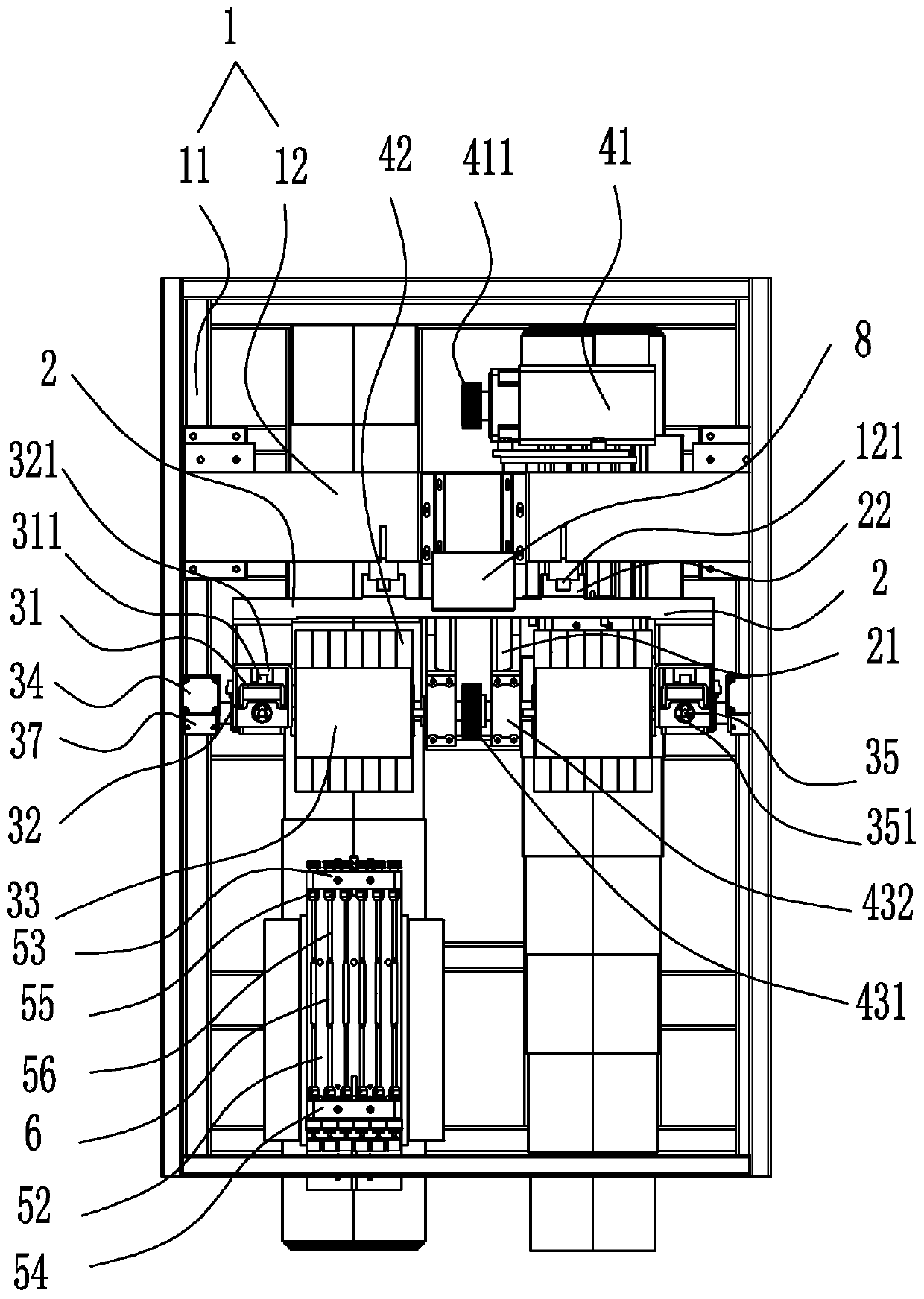

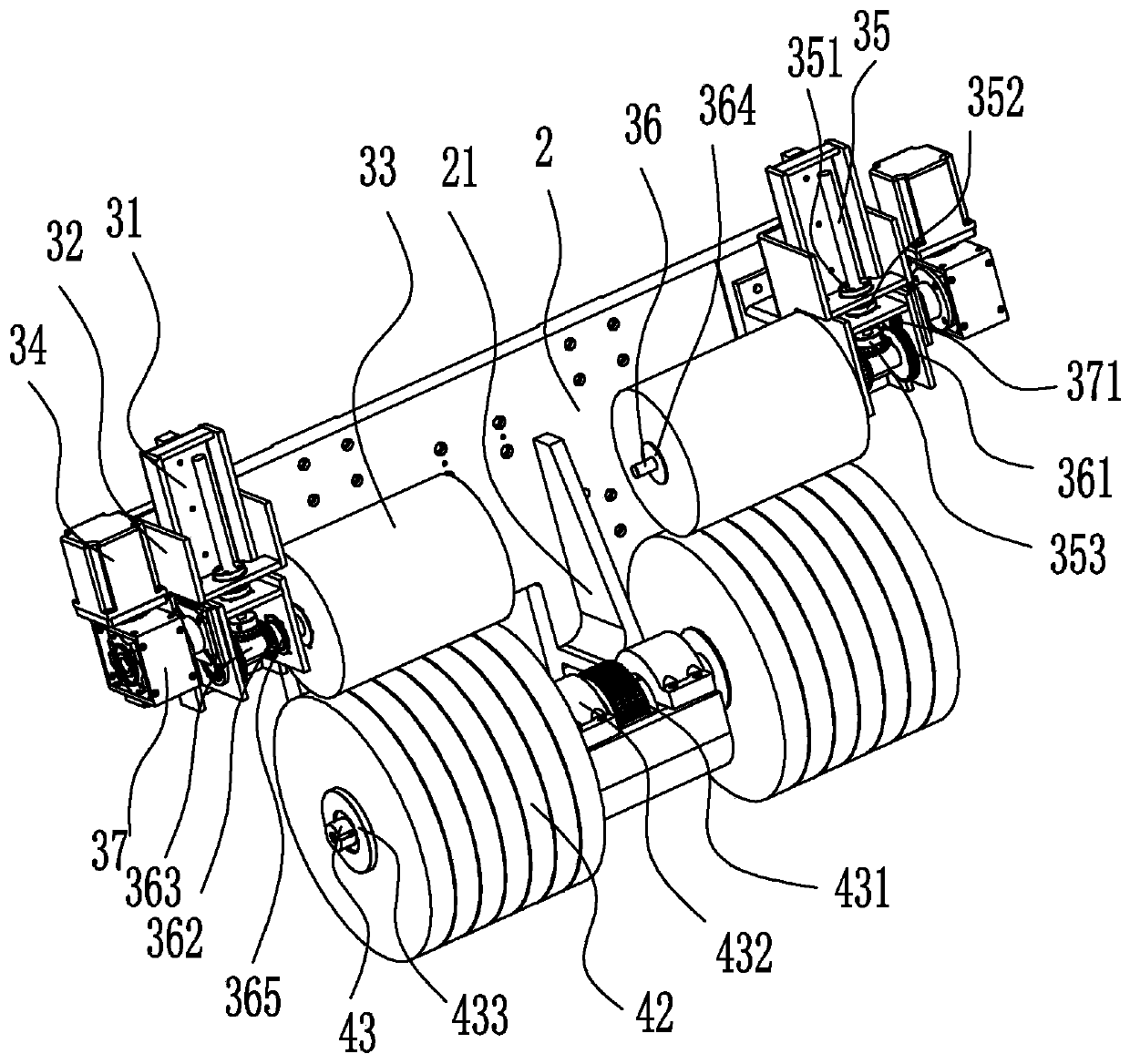

[0042] Such as Figures 1 to 9 As shown, the present invention provides the following technical solutions: an automatic metal polishing machine, including a polishing machine frame 1, and the polishing machine frame 1 includes a base 11 and a beam 12 fixed on the base 11, The crossbeam 12 is slidably connected with an installation base plate 2. The installation base plate 2 is provided with two groups of waxing mechanisms 3 arranged opposite to each other. Wax base 32, waxing slide table 31 both sides are provided with matching cylindrical polishing wax 33 and waxing motor 34, waxing base 32 and waxing slide table 31 are provided with waxing motor 34 Waxing screw rod 35, the middle part of the installation base plate 2 is provided with an integral mounting seat 21, the mounting seat 21 is provided with a polishing mechanism 4 that is compatible with the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com