An atomic layer deposition system

A kind of atomic layer deposition and fluid technology, applied in the direction of coating, metal material coating process, gaseous chemical plating, etc., can solve the problem that it is difficult to realize the rapid discharge of gas flow by reaction by-products, the process of surface deposition and the emptying of reaction by-products Separate flow control and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

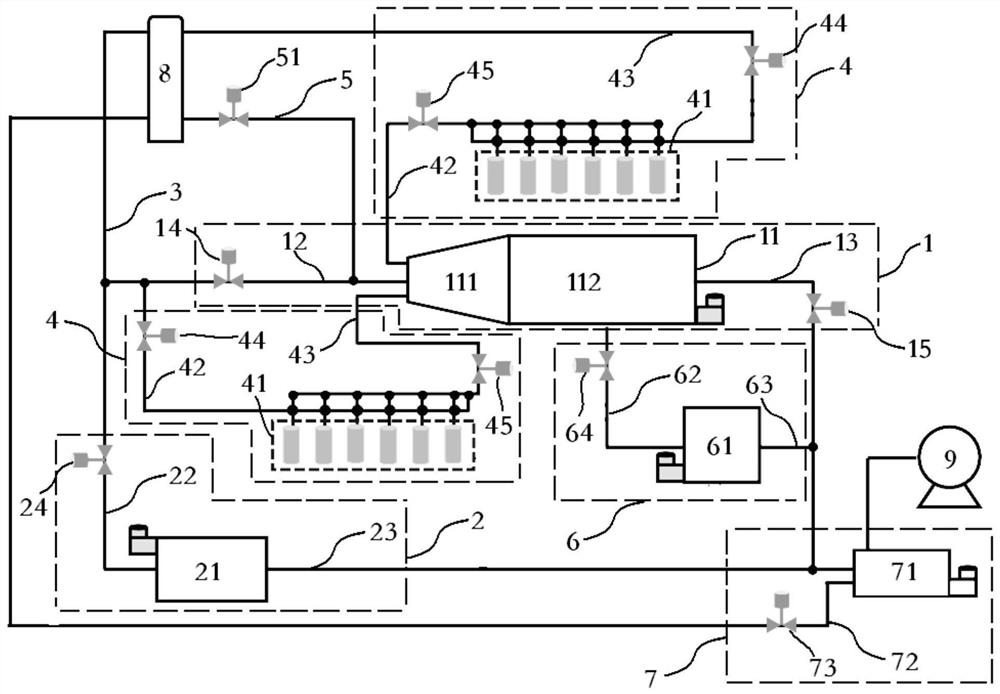

[0060] Al by atomic layer deposition 2 o 3 For example, the precursor reactants are TMA and H 2 O. TMA and H 2 The O sources are respectively installed in two different reaction source arrays (see figure 1 Two different reactant source arrays 41) in order to avoid their possible in-line mixing. The average temperature in the reaction chamber is 150°C, the sample heating temperature is 250°C, and the gas pipeline temperature is 50°C. The time sequence of reactant injection and by-product evacuation for single-layer coating is: 100 milliseconds H 2 O molecule injection + 500 millisecond reaction by-product discharge + 100 millisecond TMA molecule injection + 300 millisecond reaction by-product discharge. The system uses a BOC Edwards mechanical vacuum pump to establish a vacuum environment in the reaction chamber. Flow control adopts MKS company IP66 series mass flow controller (MFC). The gas valve adopts Swagelok company DL series atomic layer deposition special valve, ...

Embodiment 2

[0067] Atomic Layer Deposition of TiO 2 As an example, the precursor reaction sources are respectively TiCl 4 with H 2 O. TiCl 4 with H 2 The O sources are respectively installed in two different reaction source arrays (see figure 1 Two different reactant source arrays 41) in order to avoid their possible in-line mixing. The average temperature in the reaction chamber is 120°C, the sample heating temperature is 220°C, and the gas pipeline temperature is 50°C. The time sequence of reactant injection and by-product evacuation for single-layer coating is: 80 milliseconds H 2 O molecule injection + 100 milliseconds infiltration + 500 milliseconds reaction by-product discharge + 100 milliseconds TiCl 4 Molecular injection + 100 ms infiltration + 300 ms reaction by-product discharge. The film growth rate is 0.072 nm / cycle. The coating thickness is 35 nm.

[0068] h 2When the O molecule is injected, the by-product removal fluid introduction pipeline, the fluid introduction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com