RBR-based tool clamp selecting and matching method and gear hobbing machine tool clamp selecting and matching method

A tool holder and tool technology, applied in the field of tool holder selection, can solve the problems of large workload, low efficiency, and difficult to predict and control processing quality, and achieve the effect of simple expression and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

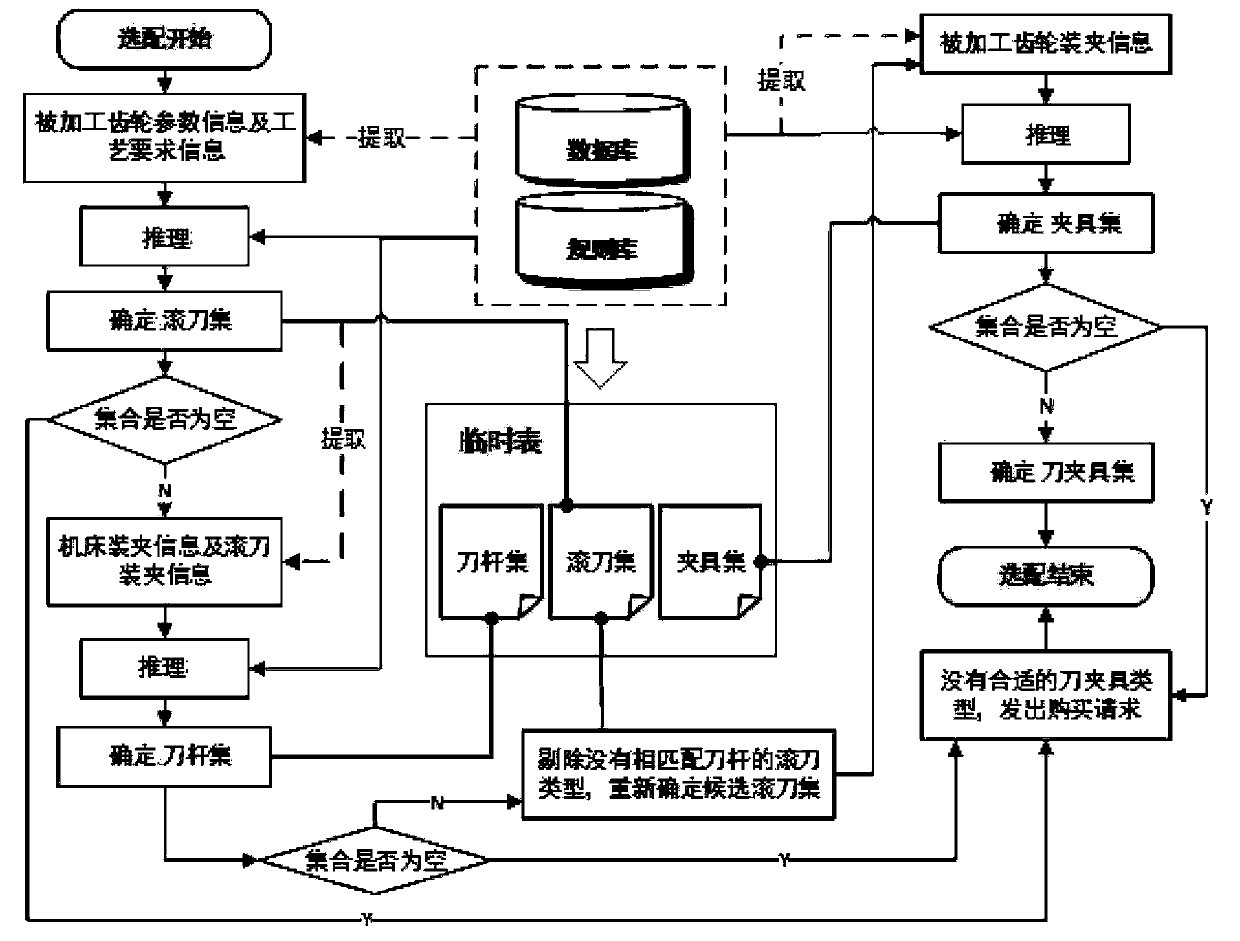

[0030] refer to figure 1 Shown, a kind of tool holder matching method based on RBR is characterized in that, comprises the following steps:

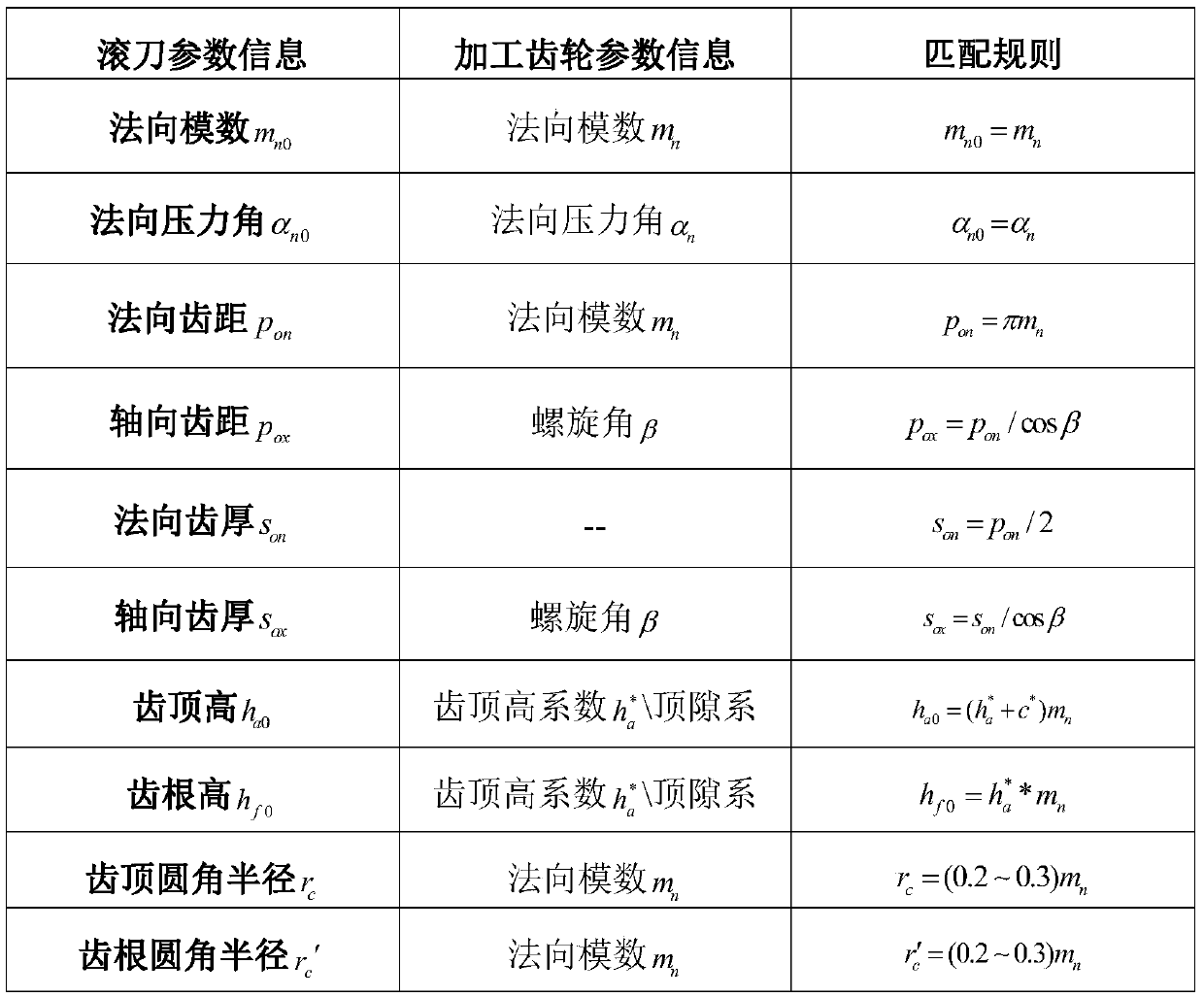

[0031] Step 1: According to the processing principle and actual processing conditions, determine the matching requirements of the tool, tool holder and fixture respectively, and establish the matching rule library according to the matching requirements; the matching rule library includes tool matching rules and tool bar matching rules Matching rules with fixtures; each matching rule is expressed in the form of production rules, and includes the rule number, condition part and conclusion part;

[0032] Step 2: Obtain processing task information and actual tool holder resource collection; the processing task information includes workpiece parameter information, processing technology information and clamping information; the processing technology information includes workpiece accuracy level, workpiece surface roughness, process and process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com