New structure of mill main engine

A new type of main engine technology, applied in the direction of grain processing, etc., can solve the problems of long downtime of the main mill, affecting the production efficiency of the mill, and complicated maintenance of the main mill, so as to shorten the maintenance process, ensure stability, increase The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

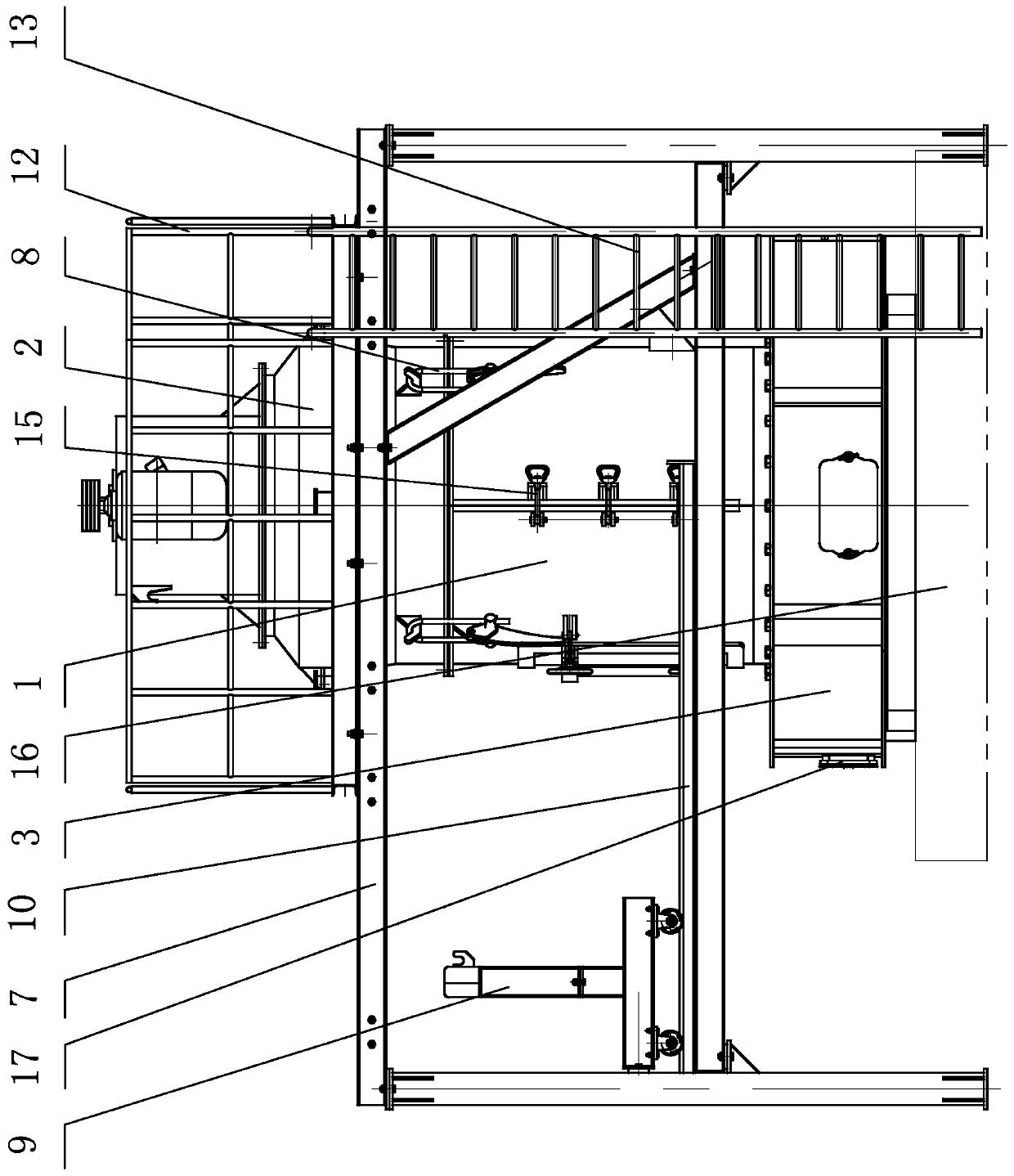

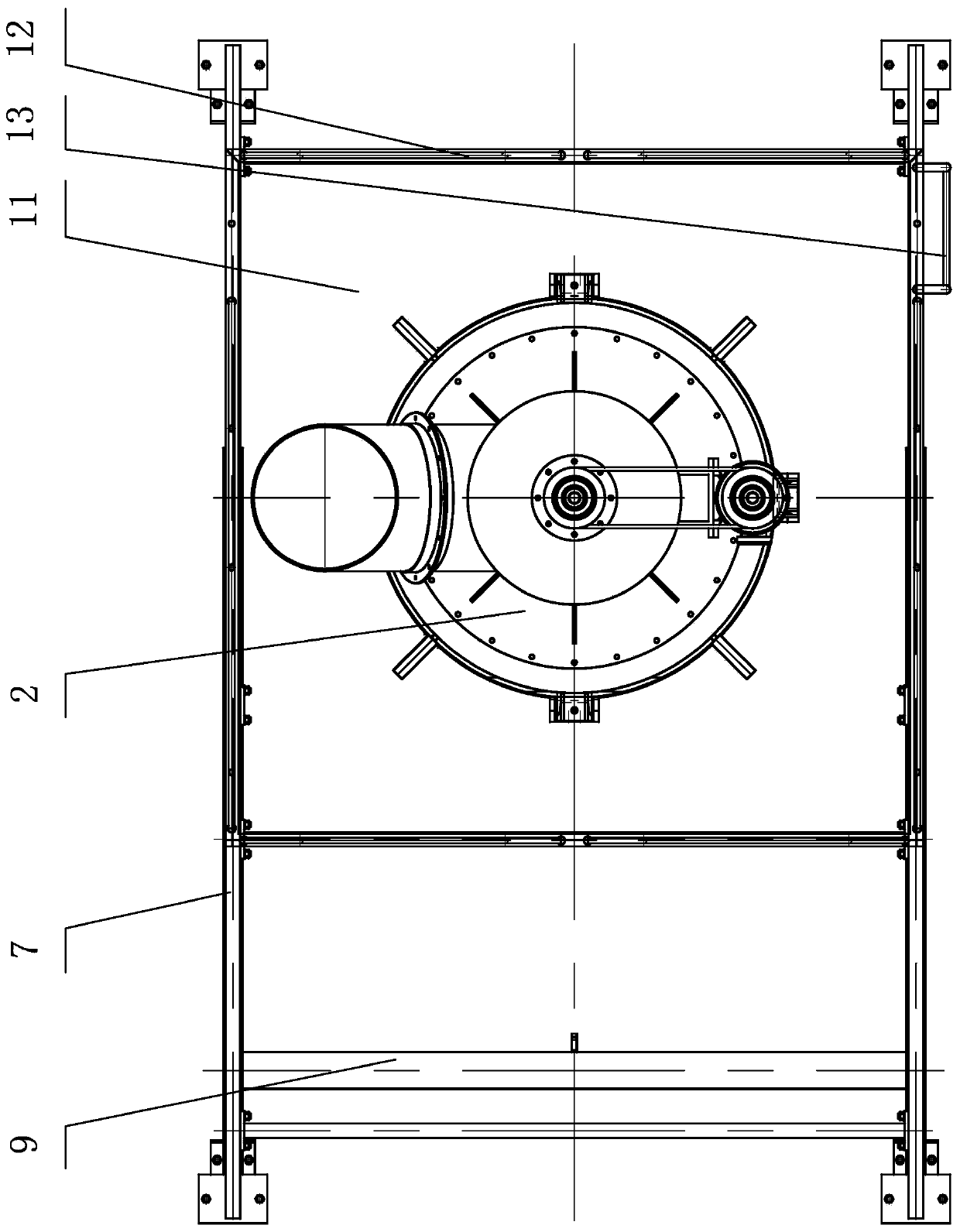

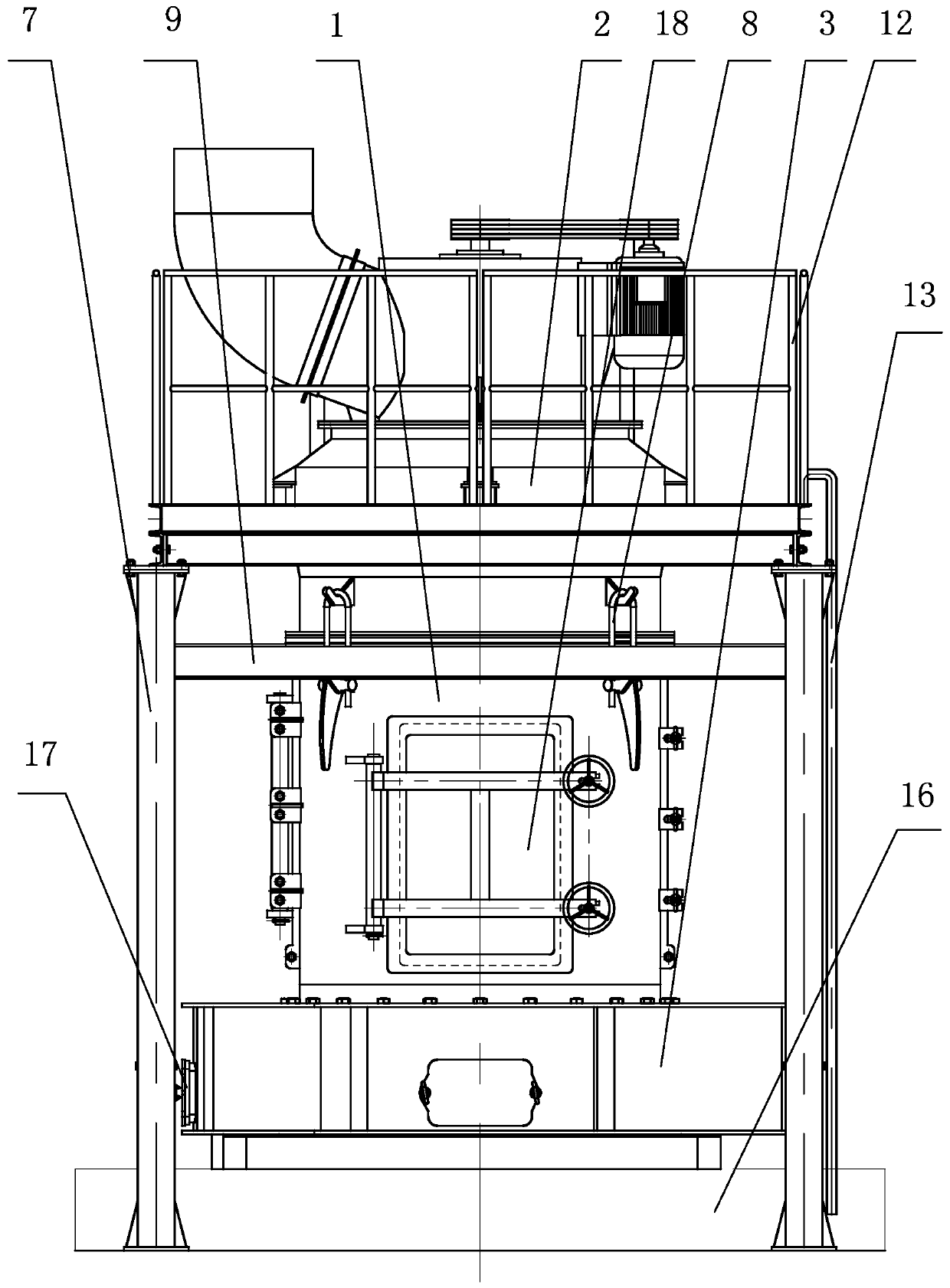

[0028] The technical solutions of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

[0029] The new structure of the mill main engine of the present invention includes a base, a return air box 3, a cover cylinder 1 and a classifier 2, the base is installed on the base 16, and the return air box 3 is supported and installed on the base 16 by a bracket and enclosed in the On the base, the tangential air inlet 17 on the air return box 3 communicates with the evenly distributed air inlets on the side of the base. One side of the inner ring of the ring plate 3-2 is installed on the top of the base by screws (coaxial with the hole of the base), and one side of the inner ring of the lower ring plate 3-3 is installed on the step at the bottom of the base by screws (coaxial with the base hole). hole coaxial), the coaming plate 3-4 is coaxially welded between the outer ring side of the upper and lower ring plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com