A film tearing robot end effector

A technology of end effectors and robots, applied in the direction of manipulators, packaging, chucks, etc., can solve the problems of wasting manpower, reducing product quality, and low production efficiency, and achieve the effects of saving manpower and material resources, significant functions, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

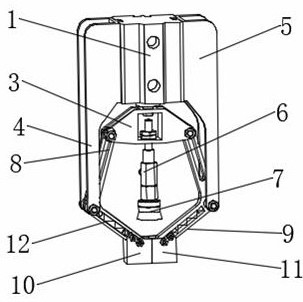

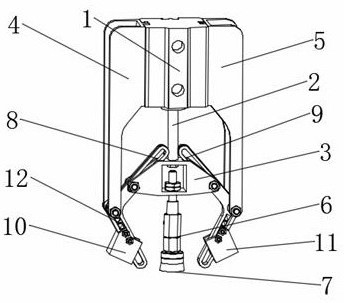

[0027] Example 1: as Figure 1-9 As shown in the figure, the end effector of the film tearing robot includes cylinder 1, movable mounting frame 3, fixed mounting frame I4, fixed mounting frame II5, vacuum adapter 6, vacuum suction cup 7, finger I8, clamp Refers to II9, clamping block I10, and clamping block II11; the clamp refers to the fixed mounting bracket I4, the clamp refers to the fixed mounting bracket II5 is installed on both sides of the cylinder 1 and is fixedly connected, and the clamp refers to the movable mounting bracket 3 is installed on the piston rod of the cylinder 1 2 The lower end, the upper ends of the clip finger I8 and the clip finger II9 are respectively connected to the two sides of the clip finger movable mounting frame 3, and the middle of the clip finger I8 and the clip finger II9 are respectively installed on the clip finger fixed mounting bracket I4 and the clip finger through the middle shaft hole. On the fixed mounting frame II5, the lower ends ...

Embodiment 2

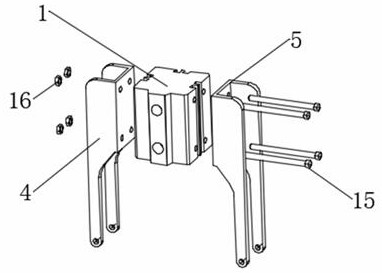

[0029] Embodiment 2: The structure of the device of this embodiment is the same as that of Embodiment 1, except that the clamping block I10 or the clamping block II11 is fixedly connected to the slider 14 through the clamping block mounting shaft 23 and the clamping block mounting nut 24; the clamping finger is fixedly installed The frame I or the clamping finger fixing mounting frame II is fixed on the cylinder 1 through the clamping finger fixing installation shaft 15 and the clamping finger fixing installation nut 16; the upper end of the vacuum adapter is threaded and fixed on the clamping finger through the vacuum adapter nut 17 Mounting frame 3.

[0030] When the above-mentioned device is used, the cylinder 1 provides the power for linear motion, and the vacuum adapter 6 connected with the piston rod 2 and the vacuum suction cup 7 at the lower end thereof can realize up and down reciprocating linear motion with the movement of the cylinder piston rod; When moving to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com