Large-scale powder bed spraying liquid bonded type three-dimensional (3D) printer

A 3D printer and bonding technology, which is applied in the direction of additive processing, processing and manufacturing, and coating devices of mixtures of solid materials and liquid materials. problems such as low efficiency, to achieve the effect of satisfying personal personalization, high printing efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

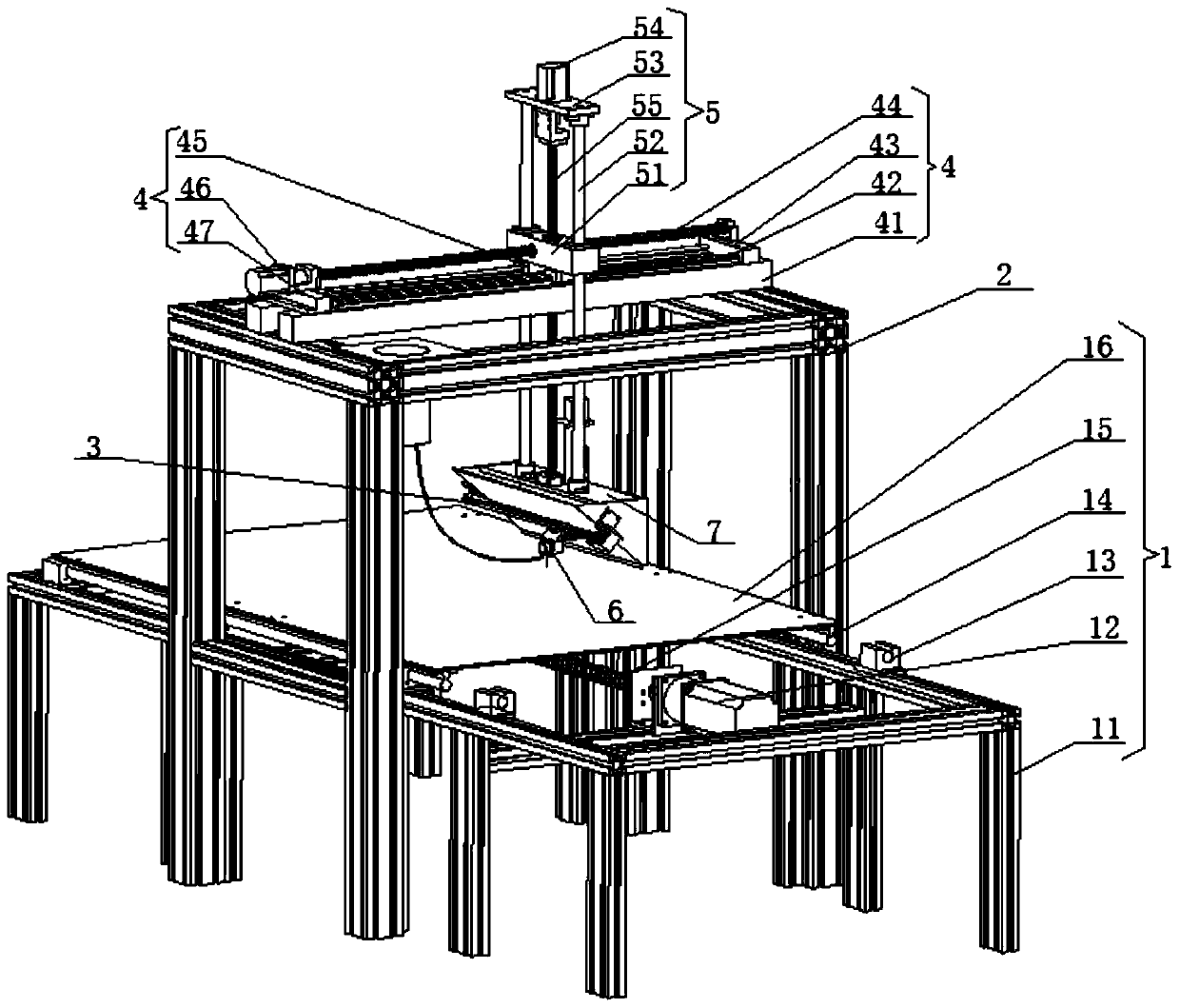

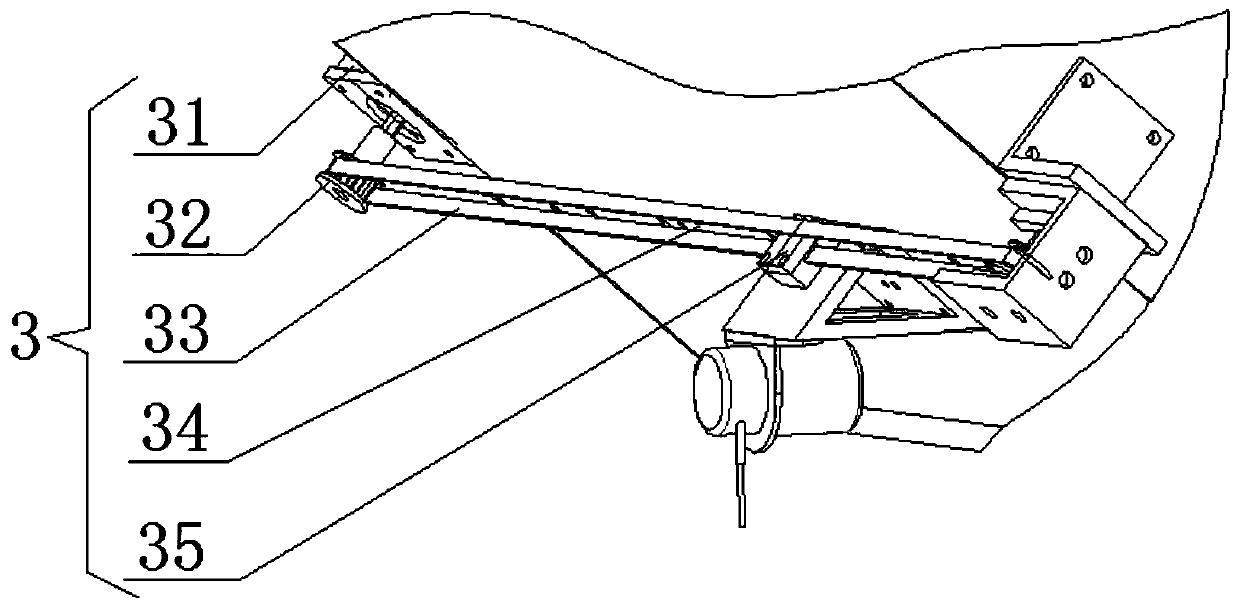

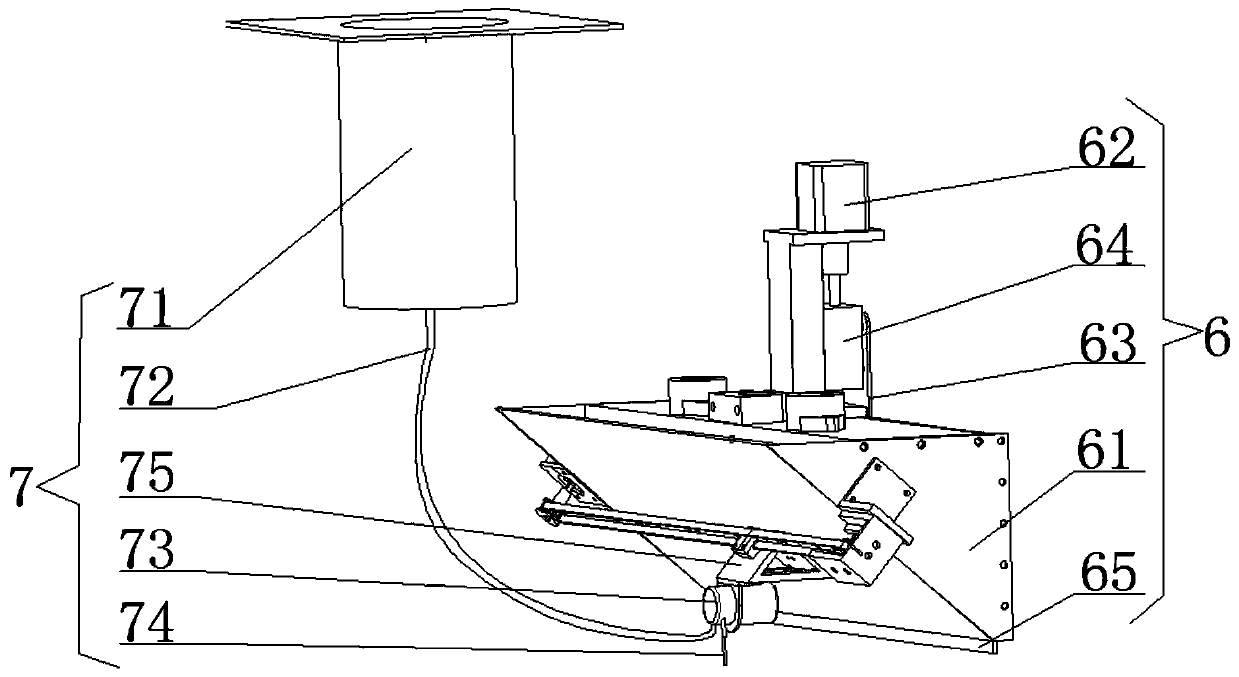

[0019] Please refer to figure 1 and figure 2 , the embodiment of the present invention provides a large-scale powder bed spray-liquid bonding 3D printer, including a movable powder bed 1, a double gantry frame 2, an X-axis motion mechanism 3, a Y-axis motion mechanism 4, and a Z-axis motion mechanism Mechanism 5, powder spreading device 6 and adhesion promoter spraying device 7.

[0020] The movable powder bed 1 includes a powder bed driving mechanism and a powder bed 16, and the powder bed driving mechanism includes a powder bed support frame 11, a powder bed driving motor 12, an optical axis guide rail slide 13, an optical axis guide rail 14 and a powder bed. Bed drive lead screw 15, the powder bed drive motor 12 is fixedly installed on the powder b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com