Quick-change device for power battery system of electric automobile and battery pack

A power battery pack and power battery technology, which is applied in electric power units, power units, vehicle maintenance, etc., can solve the problems of high cost, low positioning accuracy, complex structure, etc., and achieve reliable and safe connection, stable and reliable fixation, fast Effects of disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

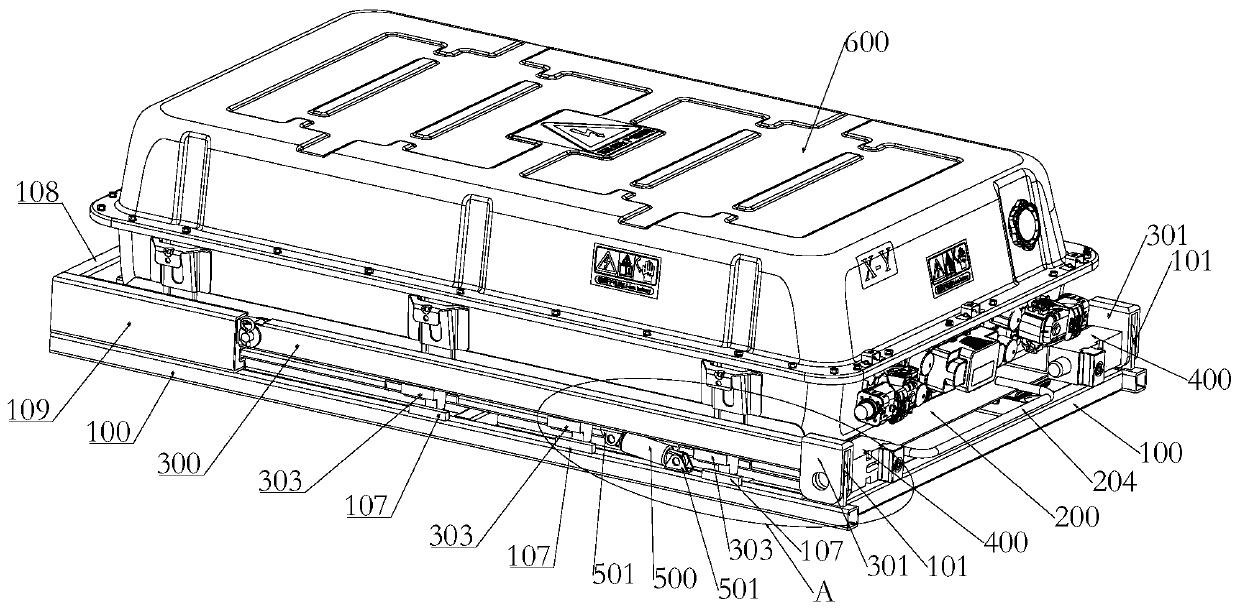

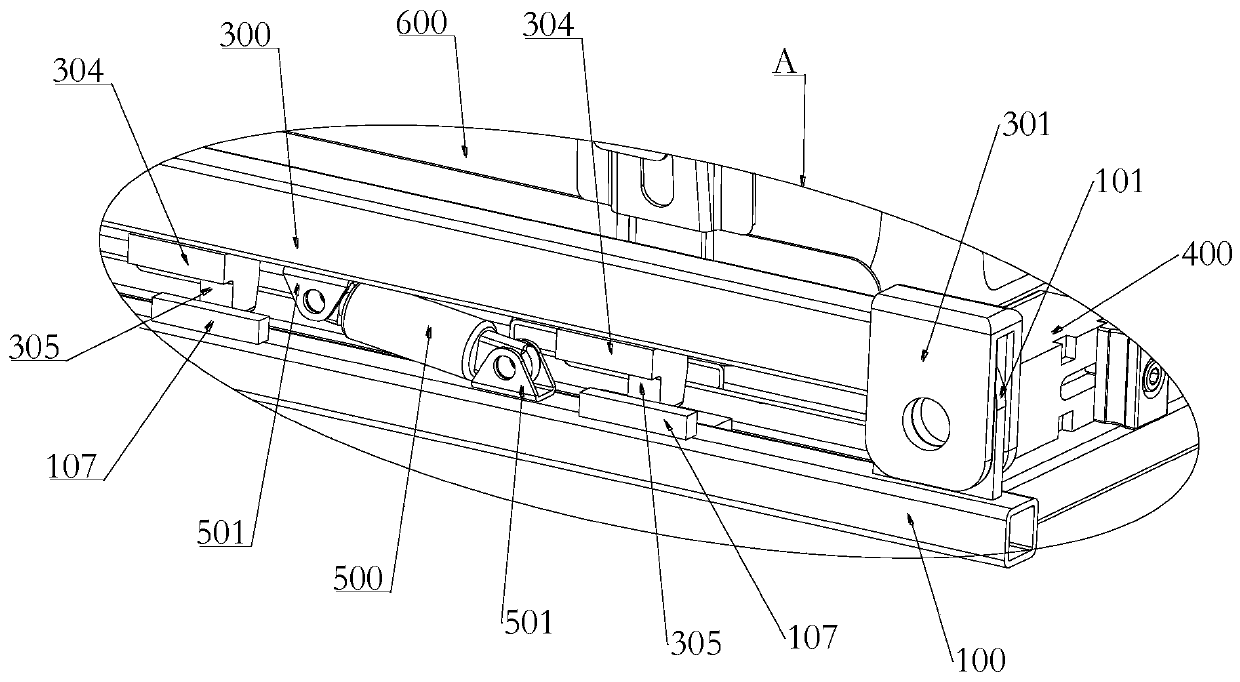

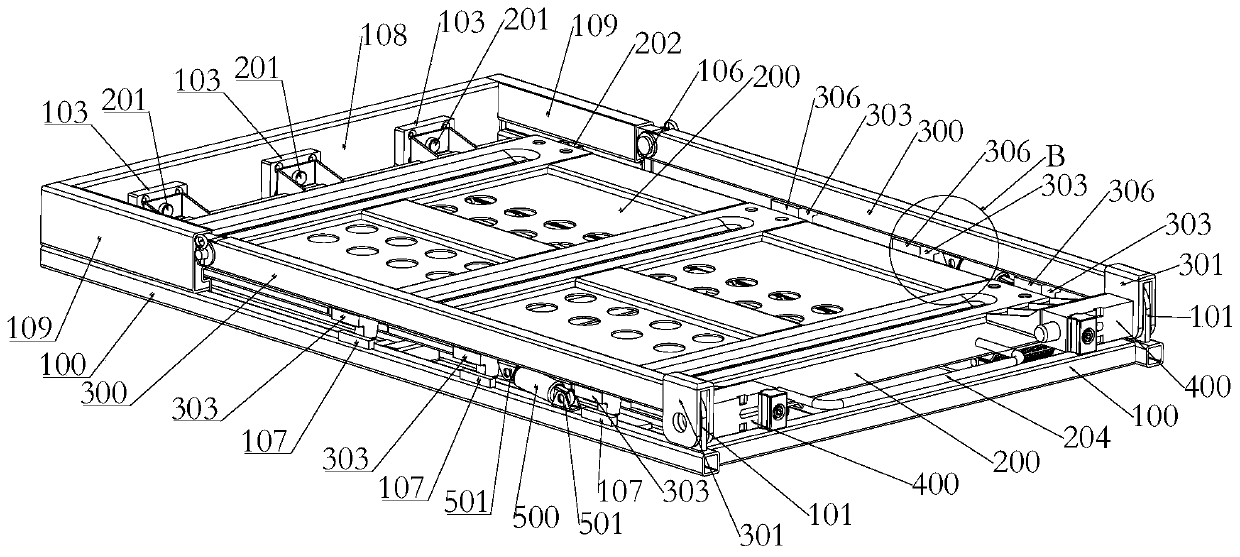

[0045] Such as Figure 1-Figure 10 As shown, a quick-change device for an electric vehicle power battery system in this embodiment includes a fixed bracket 100 and a quick-change bracket 200. The quick-change bracket 200 is used to connect the power battery pack 600 and can be slid into or Slide out the fixed bracket 100; the fixed bracket 100 is hinged with a stop bead 300, and the quick-change bracket 200 or the fixed bracket 100 or the stop bead 300 is provided with a locking structure 400, when the quick-change bracket 200 slides into the fixed bracket 100, the stop bar 300 rotates along the hinge and presses down on the quick-change bracket 200 and realizes the locking structure 400 The locking connection of the fixed bracket 100 , the quick-change bracket 200 and the stop pressure strip 300 is described.

[0046] The quick-change device of this embodiment adopts the stop pressing block and the locking structure, which can realize the mechanical locking of the quick-chan...

Embodiment approach 1

[0049] Embodiment 1, the locking structure 400 is arranged on the stop bead 300, the lock head 301 is arranged on one of the fixed bracket 100 and the quick-change bracket 200, and the lock tongue 101 is arranged on the other, when the quick-change bracket 200 slides When inserted into the fixed bracket 100, the lock head 301 and the locking hole on the deadbolt 101 overlap each other, and then use the locking structure 400 on the stop bead 300 to insert into the two locking holes for locking. . The locking structure 400 can be installed on the inside or outside of the stop bead 300 , and the end structure of the stop bead 300 can also be appropriately improved to adapt to the lock structure 400 . In order to save space, the locking structure 400 can be installed inside the locking bead 300. Since the quick-change bracket 200 slides into the fixed bracket 100, the stopping bead 300 is in an open state, and the locking structure on it 400 does not affect the sliding of the qui...

Embodiment approach 2

[0050] Embodiment 2, the locking structure 400 is arranged on the fixed bracket 100, the lock head 301 is arranged on one of the stopper bar 300 and the quick-change bracket 200, and the lock tongue 101 is arranged on the other, when the quick-change bracket 200 slides When inserted into the fixed bracket 100, the lock head 301 and the locking holes on the dead bolt 101 overlap each other, and then use the locking structure 400 on the fixed bracket 100 to insert into the two locking holes for locking. . The locking structure 400 can be installed on the outside of the fixing bracket 100 , and the structure of the outer edge of the fixing bracket 100 can also be properly improved to adapt to the locking structure 400 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com