Anti-segregation production packaging method for metal smelting drainage sand

A packaging method and metal smelting technology, applied in packaging, transportation packaging, packaging protection and other directions, can solve the problems of small particles below, sintering, material segregation, etc., to facilitate stacking and loading and unloading, improve the pouring rate, and ensure normal use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

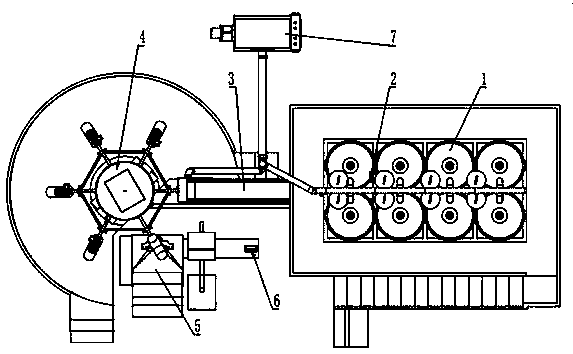

[0055] Embodiment 2 is different from Embodiment 1 in that the material bag 6 after vacuum packaging is in the shape of a cuboid, or the material bag 6 after vacuum packaging is in the shape of a cube, or the material bag 6 after vacuum packaging is in the shape of a round cake, or The material package 6 after vacuum packaging is in the shape of a triangular cake, or the material package 6 after vacuum packaging is in the shape of a cylinder.

Embodiment 3

[0056] Embodiment 3 is different from the above embodiments in that an extrusion die is set in the packaging machine 5, and the extrusion die is formed by at least two mold shells interlocked with each other. After the mold shells are interlocked, the inner The cavity is the shape of the material bag 6, the mold shell is fixed at the output end of the cylinder, the material bag 6 to be vacuumed is placed between the mold shells, the cylinder moves, and the mold shells are fastened to form a material bag 6, the packaging machine 5 vacuumizes the bag 6, and after vacuuming, heat-press seals it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com