Hoistway-free compound skip-floor elevator

A duplex and jump-floor technology, which is applied to elevators, lifts, transportation and packaging in buildings, etc., can solve the problems of high difficulty in installation and construction of household elevators, inability to remotely control, and large space occupation, so as to save building space, Improve the safety factor and reduce the effect of pulling force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

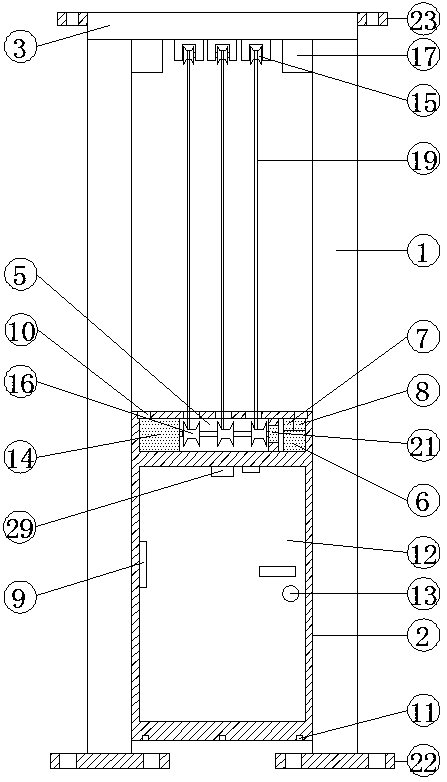

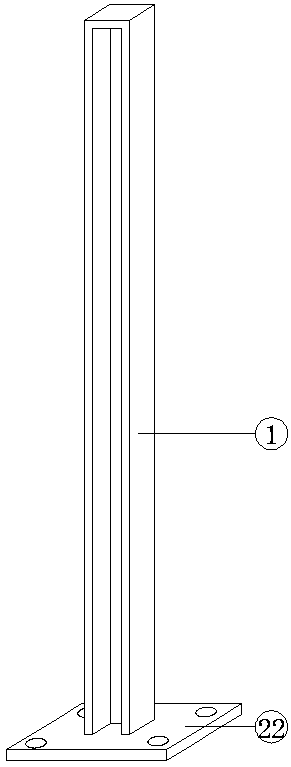

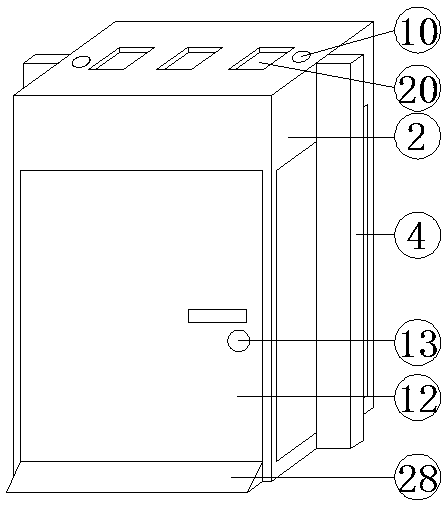

[0037] see Figure 1-7 , according to an embodiment of the present invention, a double-floor elevator without a shaft, including a guide rail 1, a car 2, a slider 4, a driving device, a PLC controller 6 and a remote controller, the number of the guide rails 1 is two and the A top plate 3 is fixed on the guide rail 1, a car 2 is arranged between the guide rails 1, sliders 4 are fixed on both sides of the car 2, and the slider 4 is connected to the slideway of the guide rail 1 , the upper end wall of the car 2 is provided with a cavity 5, the cavity 5 is provided with a driving device and a PLC controller 6, and the PLC controller 6 is provided with a wireless signal receiver 7 and a driver 8, the Both the wireless signal receiver 7 and the driver 8 are electrically connected to the PLC controller 6, a control panel 9 is fixed on the inner wall of one side of the car 2, and a control panel 9 is fixed on both sides of the upper middle of the car 2. The first infrared ranging sen...

Embodiment 2

[0040] see figure 1 , 4And 5, for drive unit, described drive unit comprises stepper motor 14, fixed pulley 15 and reel 16, and described stepper motor 14 is fixed in described cavity 5, and described stepper motor 14 and The driver 8 is electrically connected, and the outer wall of the stepper motor 14 is fixedly provided with three winding wheels 16, and the middle part of the top plate 3 is correspondingly equipped with three fixed pulleys 15. Both sides of the lower middle part of the top plate 3 are A limit block 17 is fixedly provided, and three fixed rings 18 are fixedly arranged in the cavity 5, and a steel wire rope 19 is fixedly arranged on the fixed ring 18, and the other end of the steel wire rope 19 bypasses the corresponding fixed pulley 15 and the corresponding fixed pulley 15. The reel 16 is fixedly connected, and the upper end wall of the cavity 5 is provided with three rectangular windows 20, and the rectangular windows 20 are matched with the wire rope 19; ...

Embodiment 3

[0043] see figure 1 , 3 , 4, 6 and 7, for the remote controller, the remote controller includes a housing 24, a battery 25, a processor 30 and a wireless signal transmitter 26 are fixed inside the housing 24, and the outer wall of the housing 24 A second emergency stop button, a second ascending button, a second descending button, and a second unlock button are installed, and the second emergency stop button, the second ascending button, the second descending button, and the second unlocking button are installed. The button, the battery 25 and the wireless signal transmitter 26 are all electrically connected to the processor 30, and the wireless signal transmitter 26 is matched with the wireless signal receiver 7; for the cavity 5, A backup battery 27 is fixed inside the cavity 5, and the backup battery 27 is electrically connected to the PLC controller 6; for the car 2, a triangular pad 28 is fixed under the exit end of the car 2 ; For the car 2, the top of the car 2 is equ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com