Floor substrate, floor assembly and floor

A technology for floors and base parts, applied in elastic floors, floors, covering/lining, etc., can solve problems such as damage to the service life of wooden floors, affect heat conduction, increase operating costs, etc., to achieve extended service life and strong integrity , Improve the effect of decoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

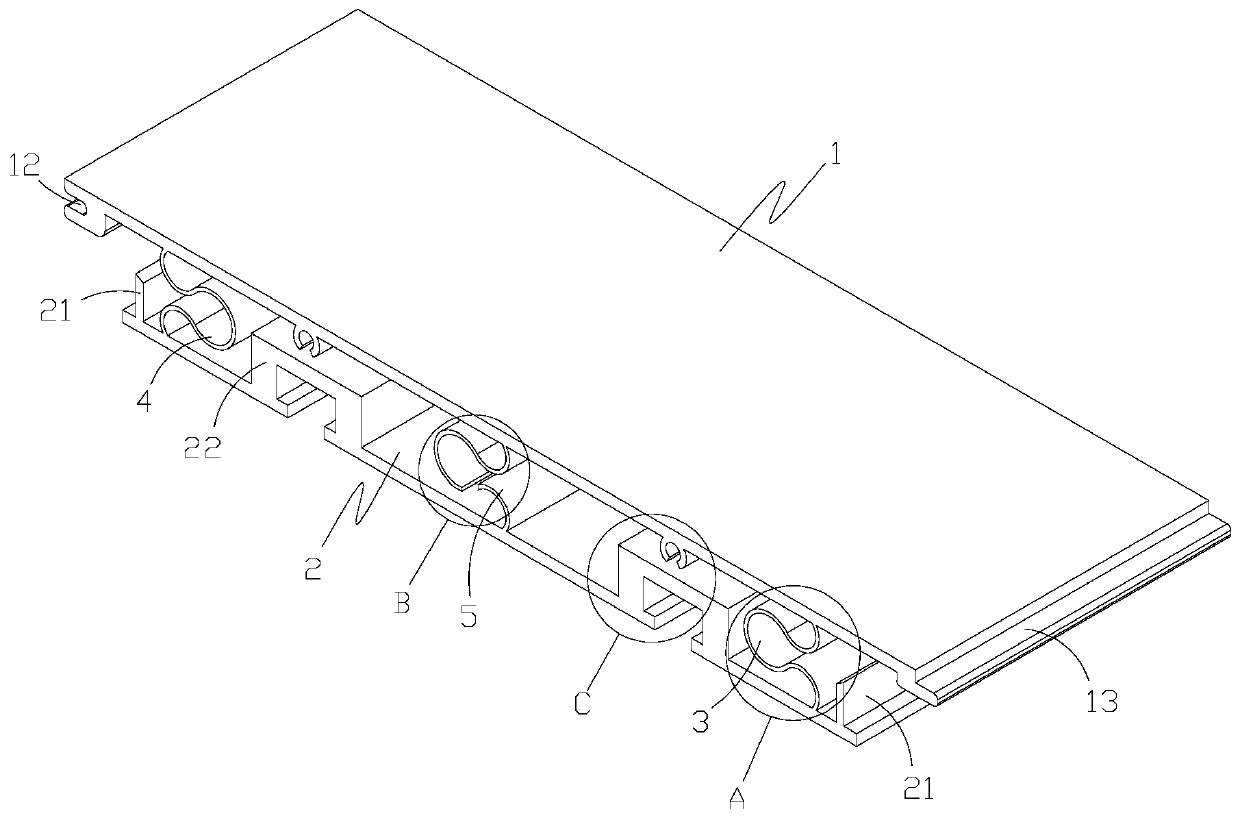

Embodiment 1

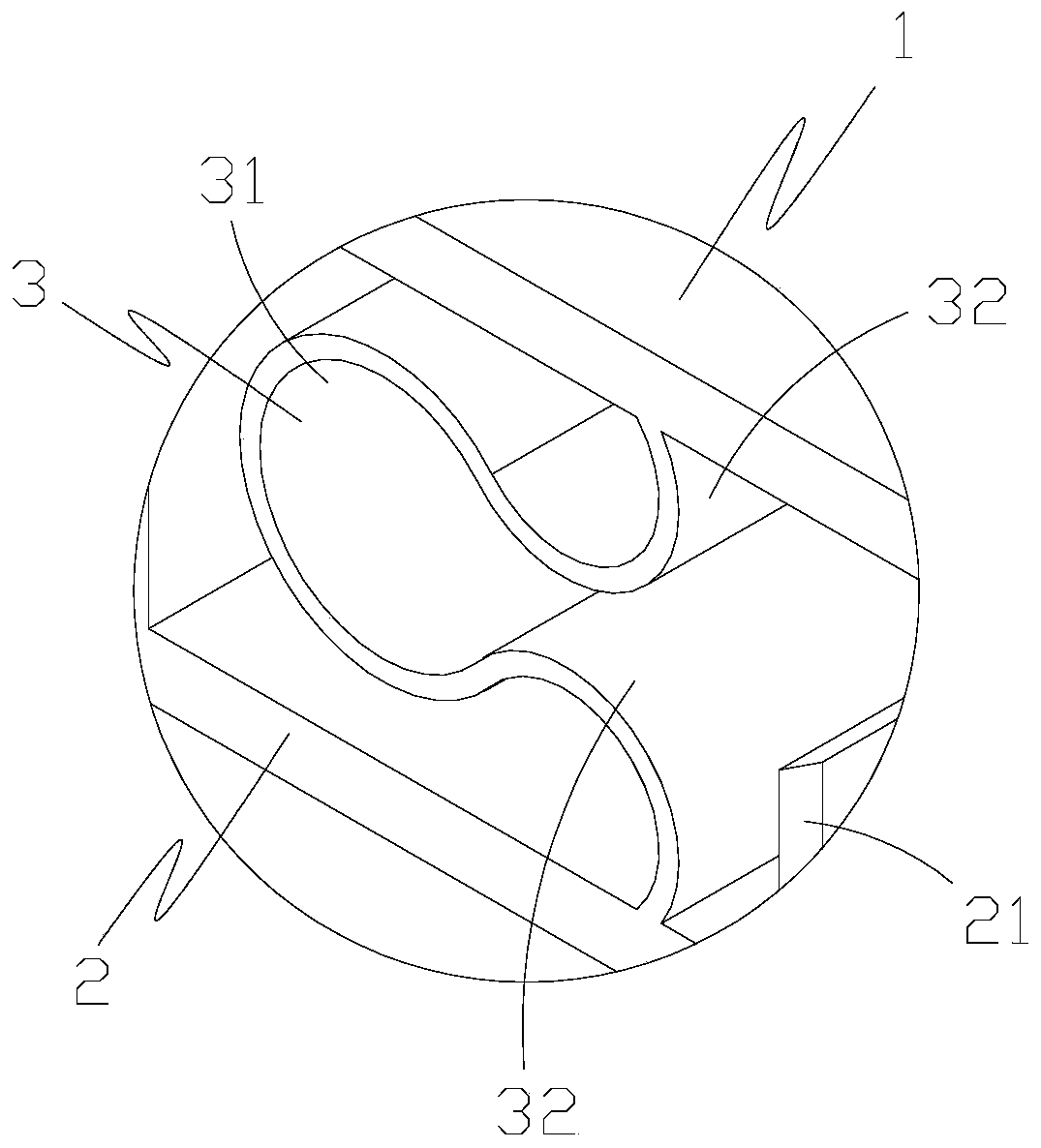

[0037] Such as Figure 1-5 As shown, a floor base member includes an upper plate 1, a lower plate 2 and an elastic connection structure; the upper plate, the lower plate and the elastic connection structure are all made of metal materials, and aluminum alloy materials are used in this embodiment. The price is low, the thermal conductivity is good, and it has a certain degree of elasticity; preferably, the floor base part can be directly processed into one piece, so that the production and processing are more convenient and the production cost is lower.

[0038] Specifically, the elastic connection structure includes a first elastic member 3, a second elastic member 4 and a third elastic member 5; one end of the first elastic member, the second elastic member and the third elastic member are connected to the bottom surface of the upper plate, and the other end It is connected with the bottom surface of the lower plate, so as to connect the upper plate and the lower plate togeth...

Embodiment 2

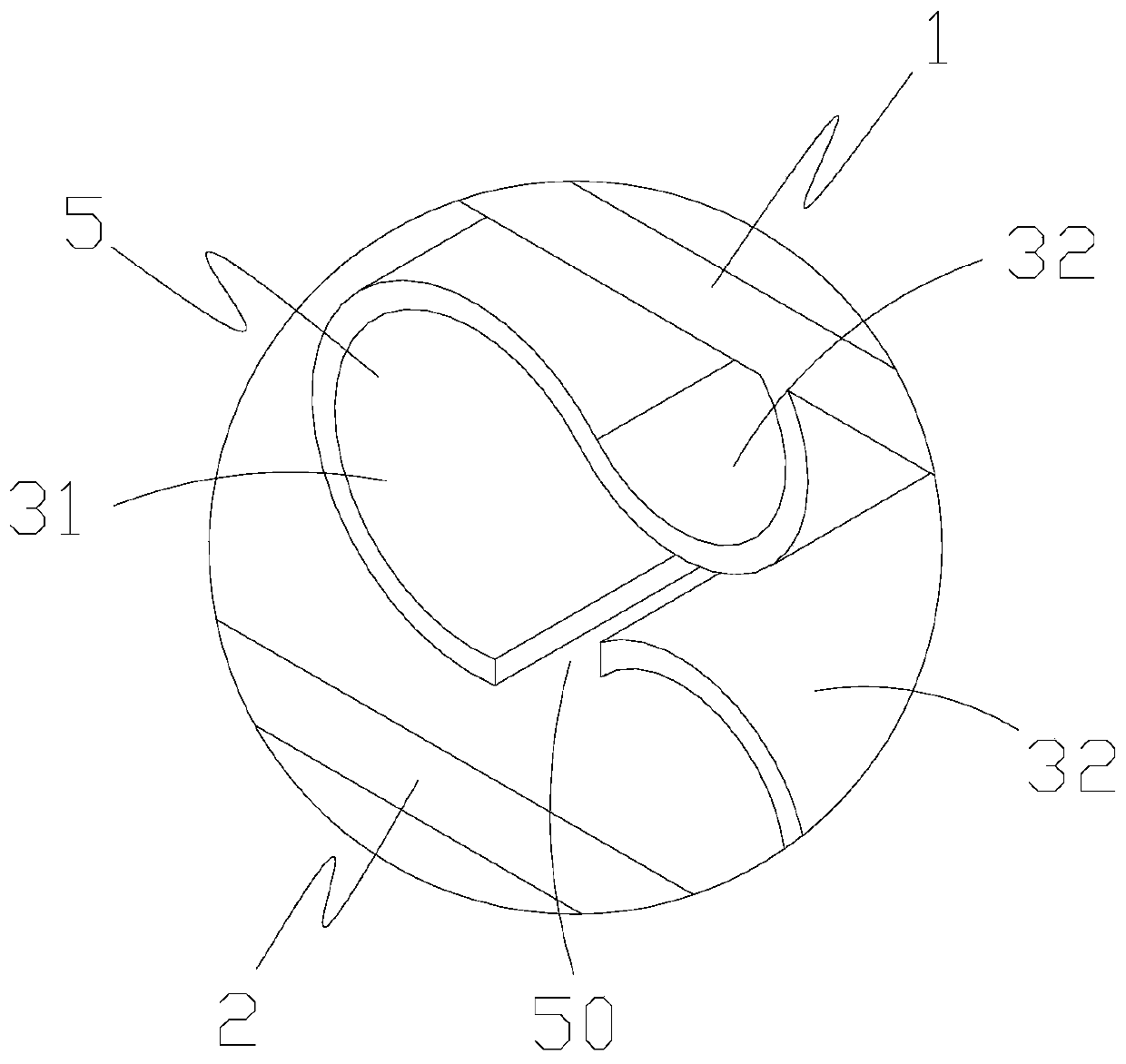

[0050] Such as Figure 6-8 As shown, the difference between this embodiment and Embodiment 1 is that the elastic connection structure includes a first elastic member 3 and a second elastic member 4, the first elastic member and the second elastic member have the same structure, but the first elastic member and the second elastic member The two elastic members are symmetrically opened with respect to the vertical plane where the middle parts of the upper plate 1 and the lower plate 2 are located, so that the supporting force received by the upper plate is more uniform; two first elastic members 3 and two elastic members are installed in total in this embodiment. For the second elastic member 4, in other embodiments, different sets of the first elastic member and the second elastic member can be installed, as long as the number of the two is the same or the elastic force and supporting force formed are the same.

[0051] Specifically, the first elastic part 3 and the second elas...

Embodiment 3

[0055] Such as Figure 9 As shown, a floor assembly includes the above-mentioned floor base and a wooden layer 8 arranged on the floor base, the wooden layer is bonded to the upper board 1 by glue, and the wooden layer is pressed tightly by a cold press On the upper plate, the two are bonded as a whole to ensure the smoothness of the wooden layer, and finally the corners are processed and polished to make the finished product more beautiful; the wooden layer is veneer with a thickness of about 1mm-8mm. This implementation In the example, it is specifically 3mm; the wooden layer can use veneer made of different woods according to different needs, such as teak wood can be used for high-end home interior decoration, and because the main body of the floor assembly is a floor base made of metal, only the surface A thin layer of teak veneer is laid, so even if expensive teak is used, the cost will not increase too much, but it can achieve better decoration effect and user experience...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com