Labyrinth sealing structure

A technology of labyrinth seal and sealing structure, which is applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems that the overall sealing structure cannot be assembled, is not easy to disassemble, and the integral structure is not easy to disassemble and assemble, so as to achieve easy processing and assembly The method and structure are simple, and the sealing effect is safe and reliable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

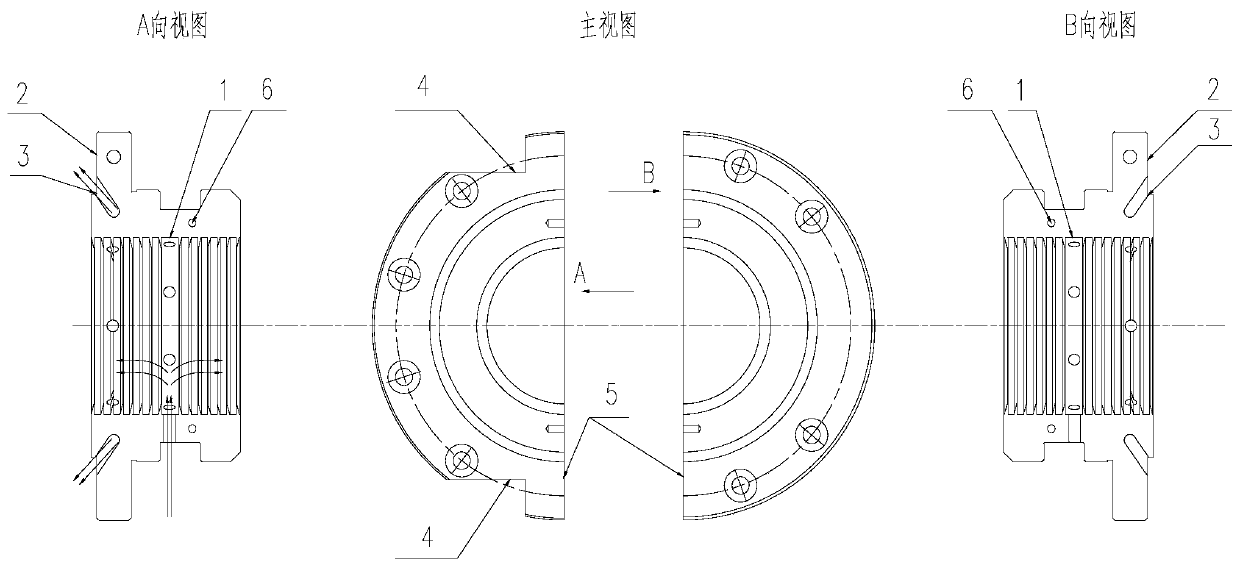

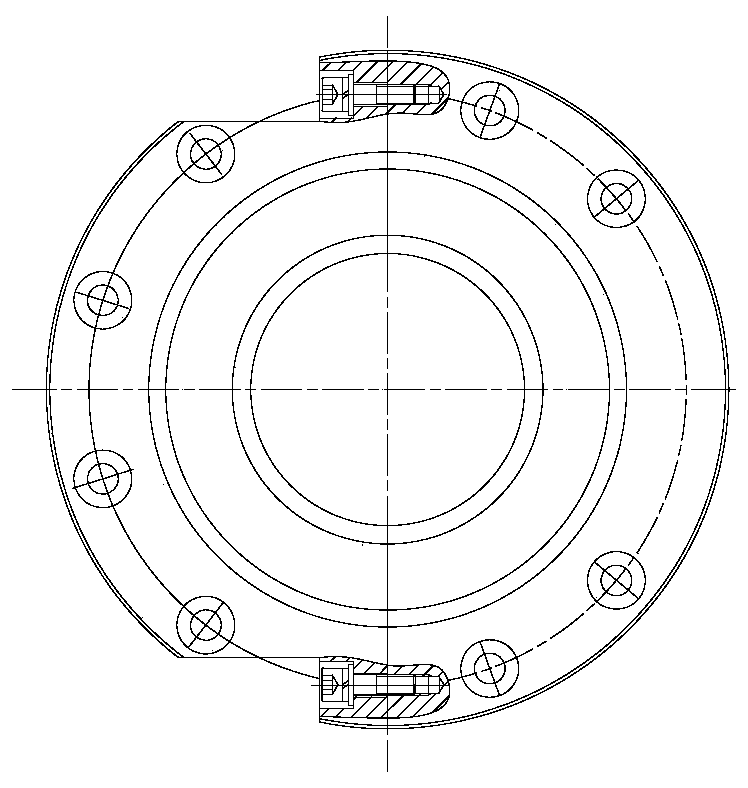

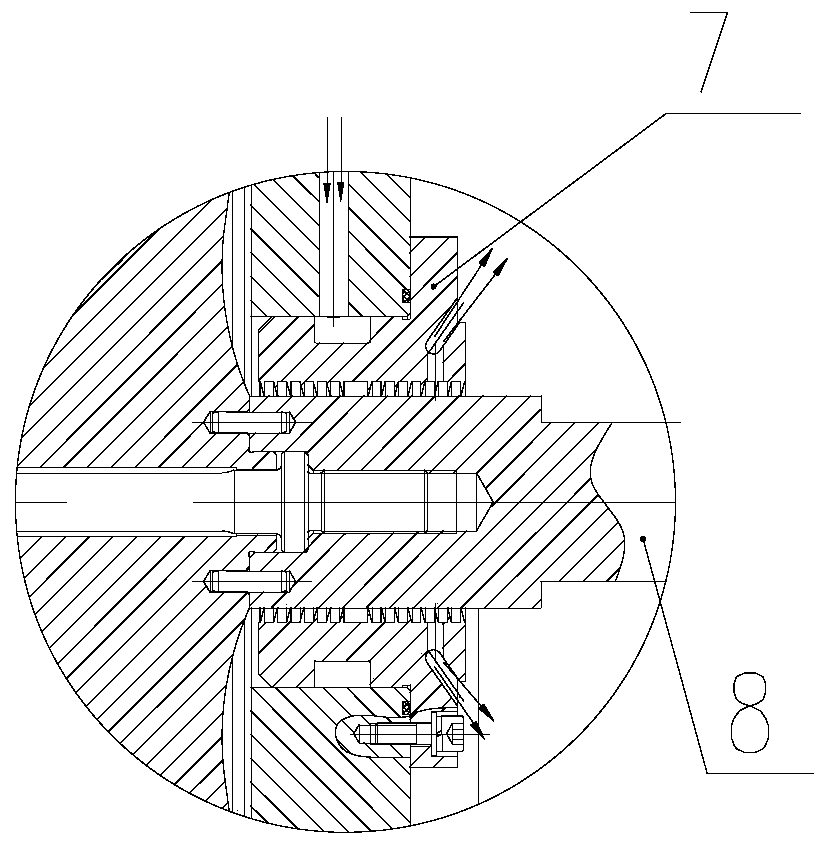

[0018] A labyrinth seal structure adopts a labyrinth seal structure with right-angled trapezoidal teeth, and is generally set as a left and right two-part labyrinth seal structure. There are 15 grate teeth on the seal body, divided into 2 groups, and an annular space is left between the 2 groups 1 , where a number of radial through holes are evenly distributed along the circumferential direction, and the sealing gas flows from here to the left and right parts of the labyrinth seal structure on both sides; the end face 2 is provided with a continuous annular groove 3 along the circumferential direction, and the annular groove 3 is a In the inner chute, a number of radial holes are set on the outer peripheral surface of the grate tooth near the upper end surface 2 to communicate with the annular groove 3, and the sealing gas flows out from here; the left flange is provided with two L-shaped grooves 4, and the L-shaped groove A round hole is arranged on the surface parallel to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com