Coupling height measuring scale

A technology of height measurement and coupling, applied in the field of measurement, can solve the problems of difficult measurement, low efficiency, large error, etc., and achieve the effect of rapid measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

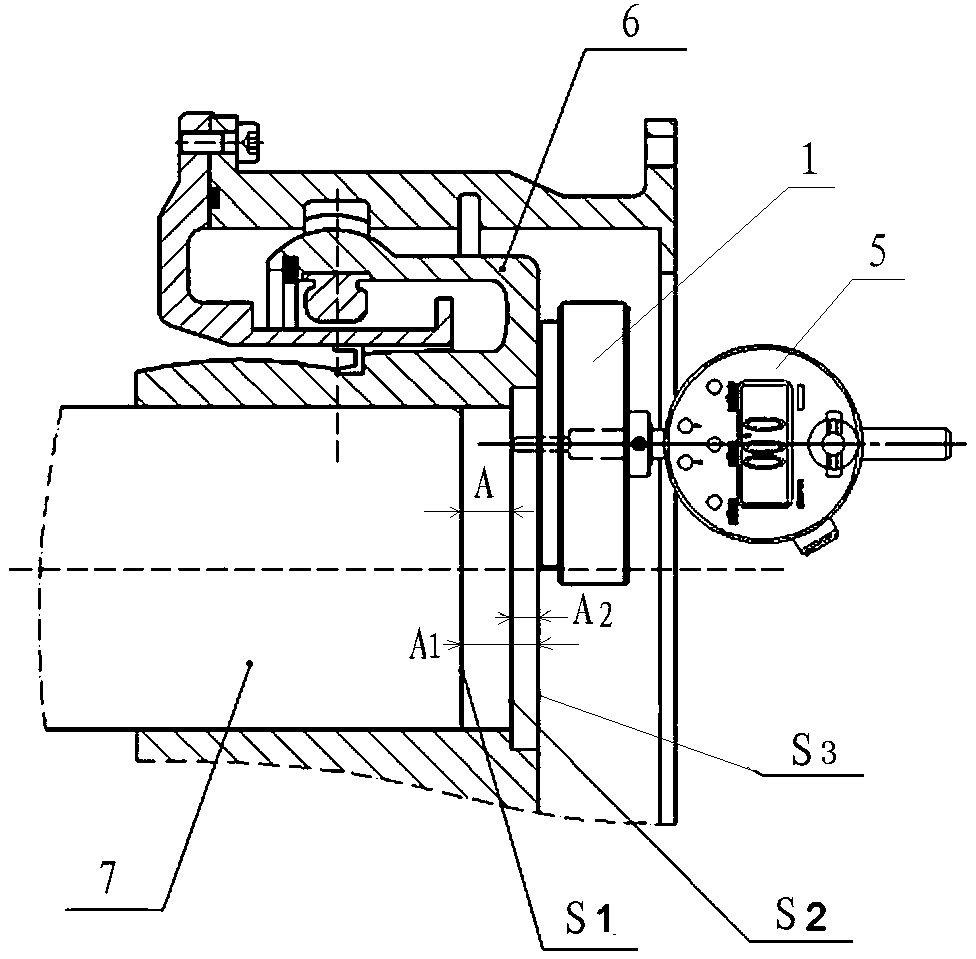

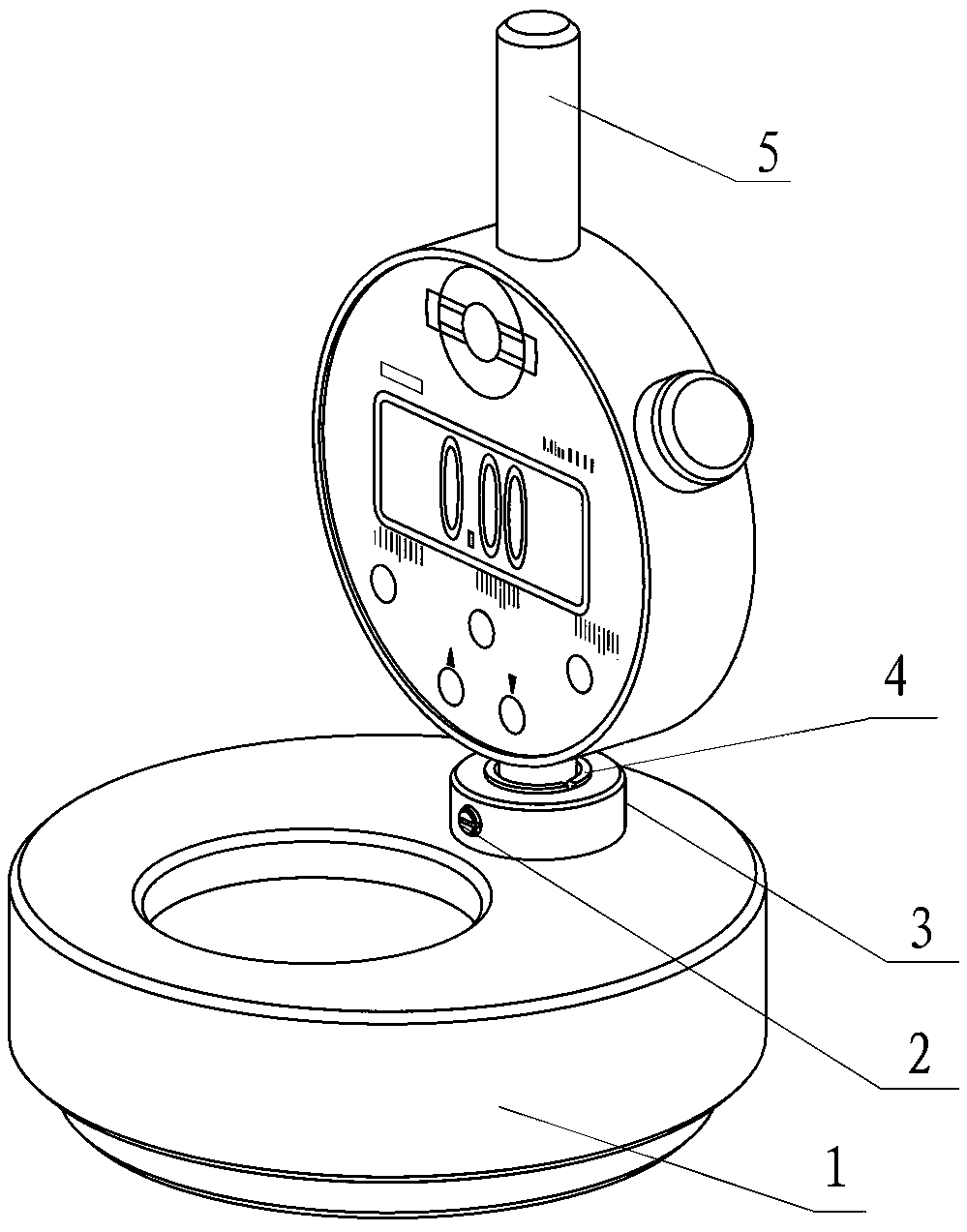

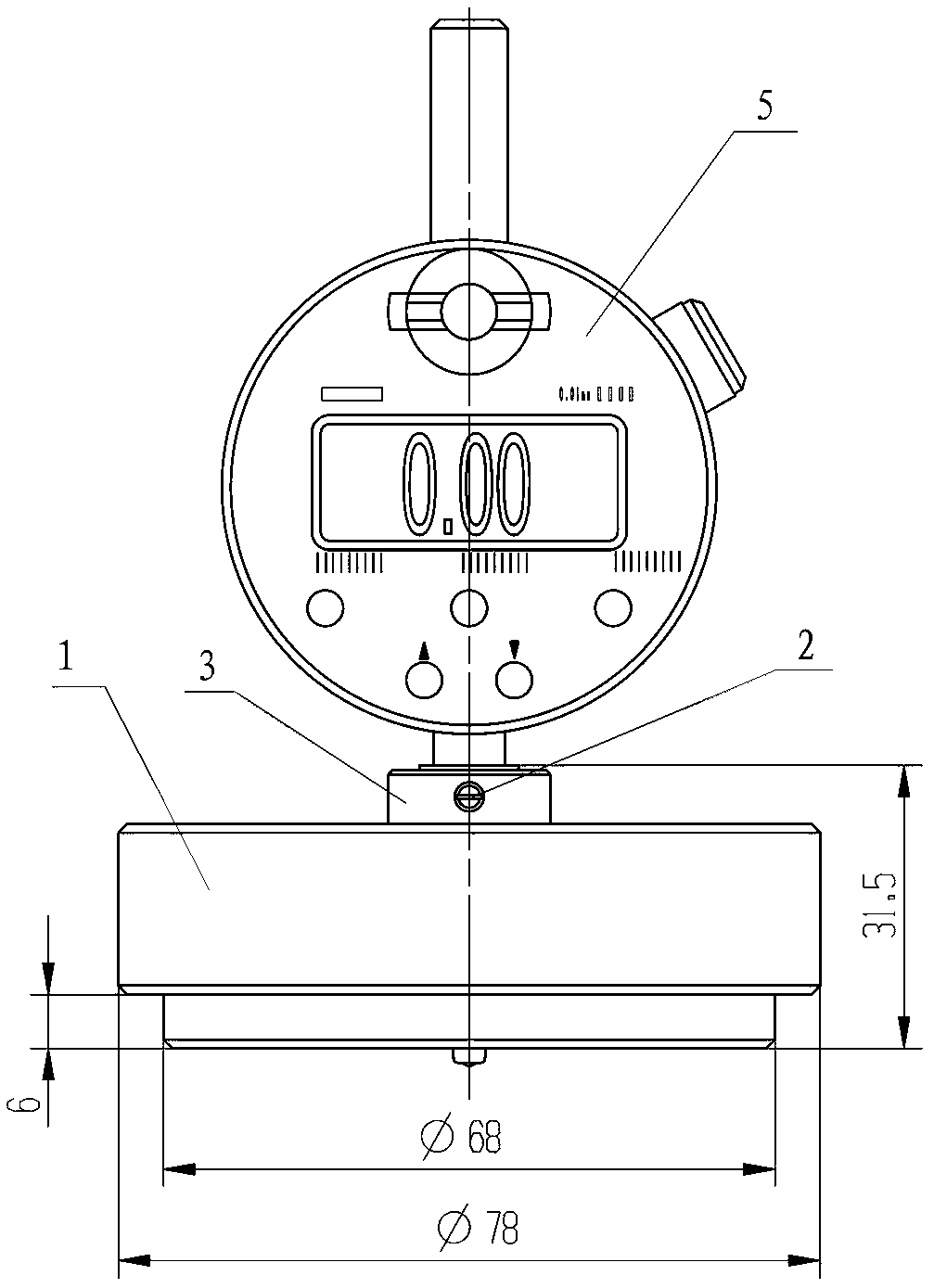

[0025] figure 2 , image 3 and Figure 4 The shaft coupling height measuring ruler, including base 1, table base 3, copper sleeve 4 and digital indicator 5; Figure 5 , Figure 6 and Figure 7 As shown, the lower end of the base 1 is set as a measuring boss 1-3, and the bottom end surface is a positioning surface as a measuring reference, that is, the measuring reference plane S3; the base 1 is provided with a table seat hole 1-1 for installing the table seat 3 and a The observation round hole 1-2 is used to observe the measurement situation, and the observation round hole 1-2 also has the function of reducing weight; the upper side of the base 1 is provided with a mesh pattern 1-4 for easy handling, avoiding slipping, and enhancing rotation flexibility. The structure and precision requirements of table base 3 are as follows Figure 8 , Figure 9 and Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com