Compressor piston manufacturing method and piston accurate grinding clamp of centerless cylindrical grinder

A manufacturing method and technology of cylindrical grinding machine, which are applied in the direction of manufacturing tools, grinding machines, and machine tools designed for grinding the rotating surface of workpieces, etc., can solve the problems of low efficiency and do not give how to improve the piston precision and piston production efficiency, etc. Low cost, shortened replacement and adjustment time, and low storage requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

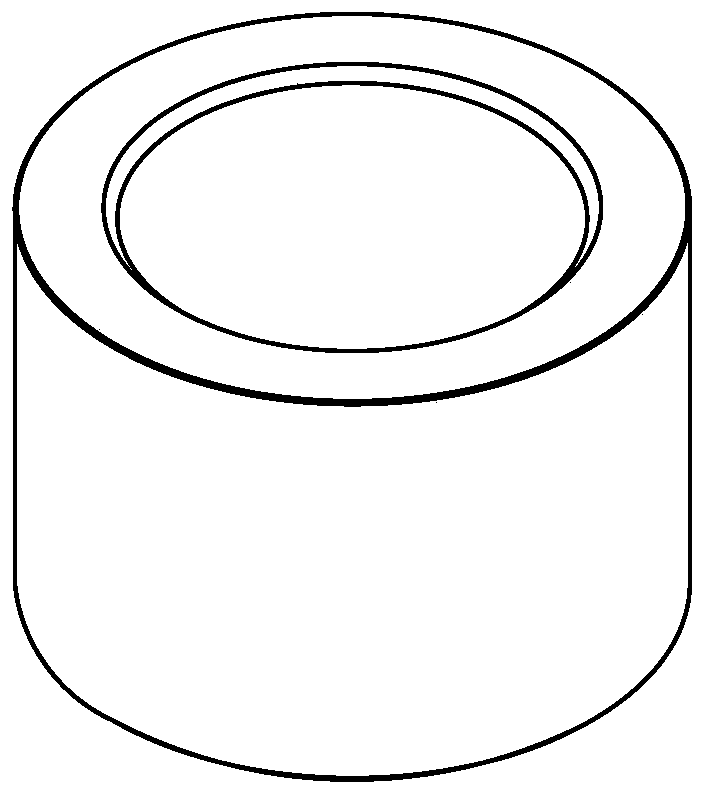

[0037] A method for manufacturing a piston of a rotary piston compressor, comprising the steps of:

[0038] In the first step, the seamless steel pipe made of Gcr15 bearing steel is selected as the raw material, and the seamless steel pipe is in a normalizing state. The seamless steel pipe is cut into piston blanks according to the length of the piston by an automatic cutting machine.

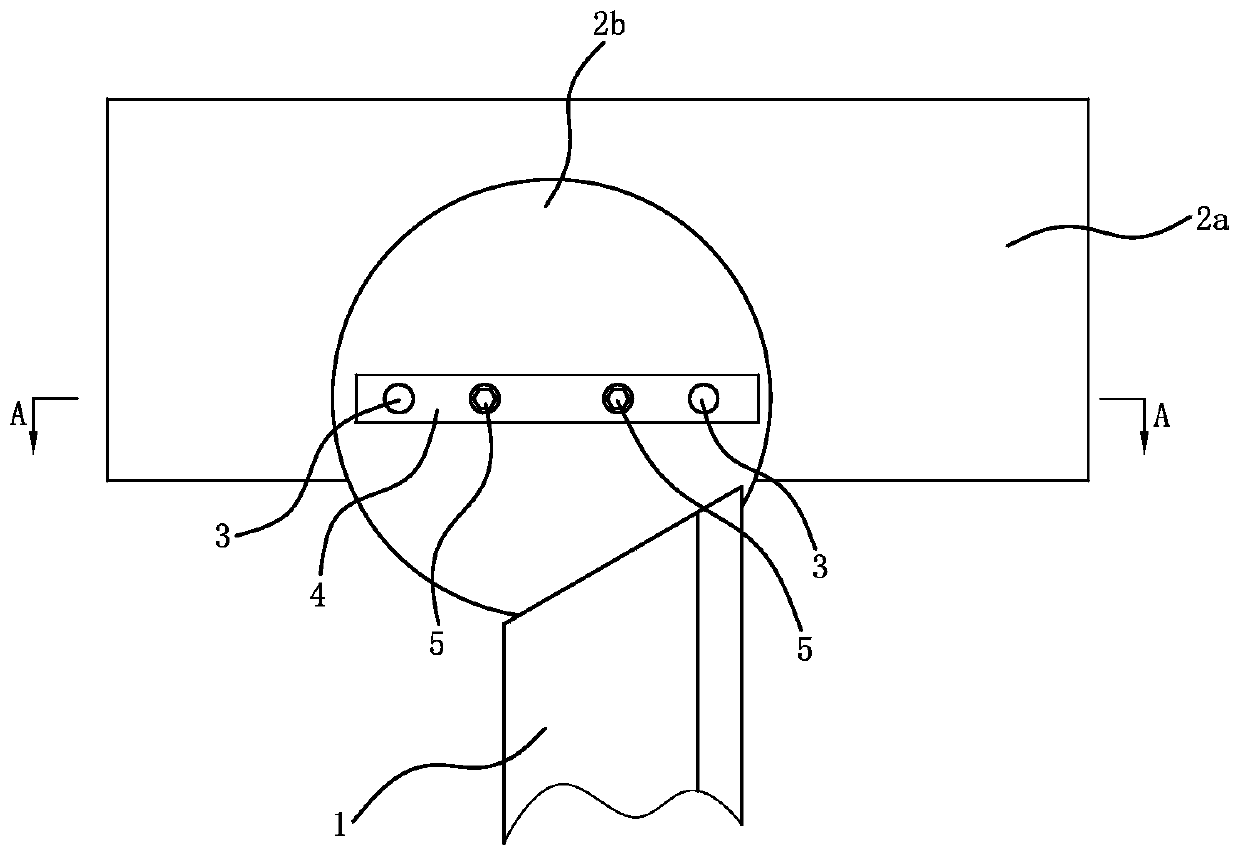

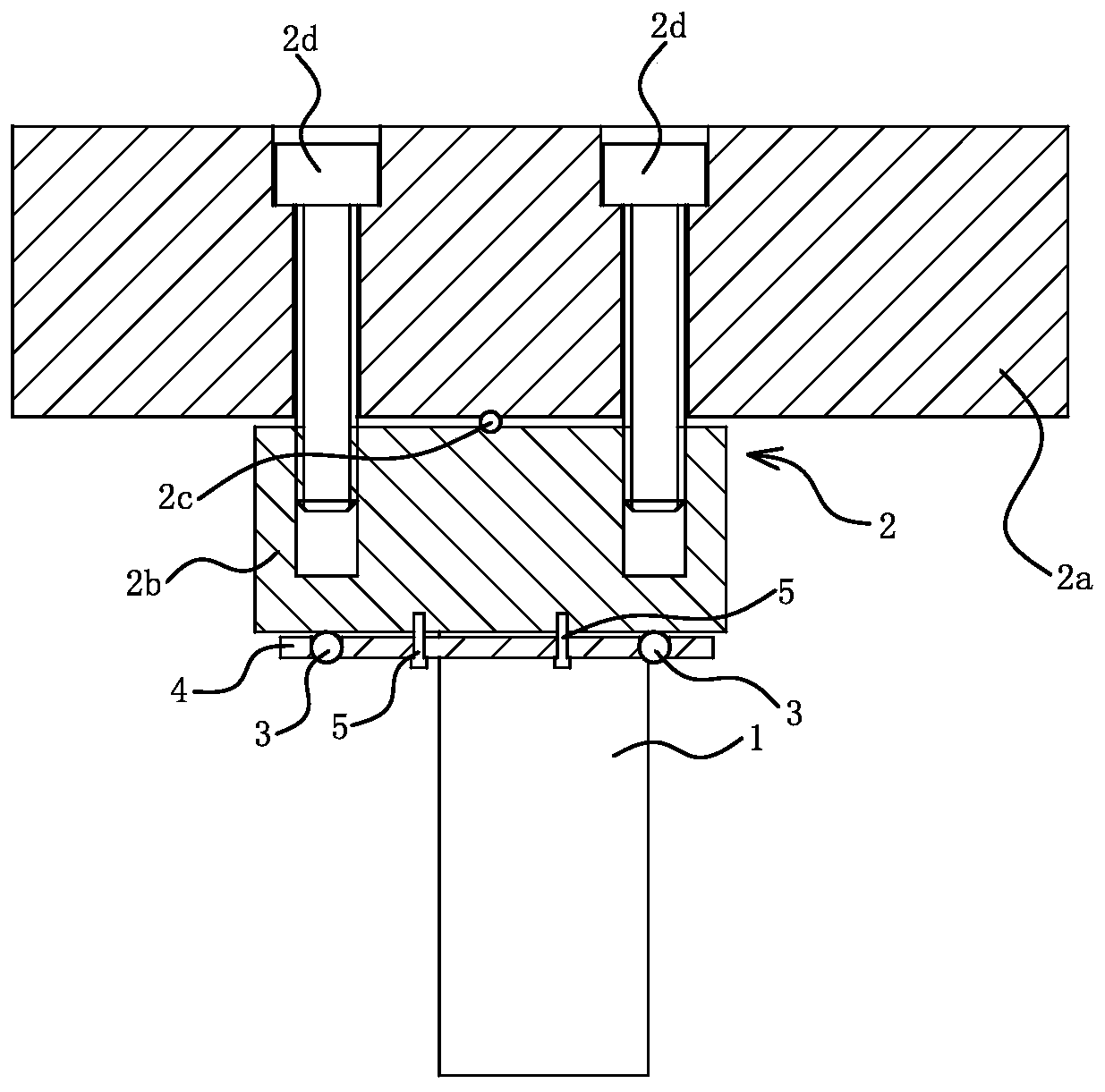

[0039] In the second step, the two end faces of the piston blank are firstly ground with a double-plane grinder, and the parallelism of the two end faces of the piston blank is ≤0.04mm. Then use a centerless cylindrical grinder to grind the outer circular surface of the piston blank. During the process of grinding the outer circular surface of the piston blank, use the piston stacking and clamping device to make the end faces of multiple piston blanks overlap and stick to each other. . Finally, a CNC lathe is used to roughly bore the inner hole of the piston blank.

[0040] In the third step...

Embodiment 2

[0053] The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be described repeatedly, only the differences are described, and the differences lie in the fourth step of the piston manufacturing method of the rotary piston compressor. In the fourth step of the embodiment, firstly, use a centerless cylindrical grinder to roughly grind the outer circular surface of the piston blank that has been processed in the third step. The end surfaces of multiple piston blanks are sequentially stacked and closely attached; after rough grinding, the perpendicularity of the end faces of the piston blanks to the outer circular surface is ≤0.04mm. Then the two end surfaces of the piston blank are semi-finely ground by a double surface grinder, and the parallelism of the two end surfaces of the piston blank is ≤0.02mm. Finally, a centerless cylindrical grinder is used to half-grind the outer circular surface of the pisto...

Embodiment 3

[0055] The structure and principle of this embodiment are basically the same as that of Embodiment 1, and the basic similarities will not be described repeatedly, only the differences are described, and the differences lie in the fourth step of the piston manufacturing method of the rotary piston compressor. In the fourth step of the embodiment, firstly, the two end surfaces of the piston blank processed in the third step are roughly ground with a double-surface grinder, and the parallelism of the two end surfaces of the piston blank is ≤0.03mm. Then use a centerless cylindrical grinder to roughly grind the outer circular surface of the piston blank. During the process of rough grinding the outer circular surface of the piston blank, use the piston stacking and clamping device to make the end faces of multiple piston blanks overlap and adhere to each other. ; After rough grinding, the verticality of the end of the piston blank to the outer circular surface is ≤0.04mm. Next, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com