Track link hot stamping cutting tool edge die

A technology of hot punching and chain rail joints, which is applied in the direction of metal chains, etc., can solve the problems of short service life, low vertical precision of both sides of forgings and the upper and lower sides, and achieve the effect of high verticality and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The implementation of the present invention will be described in detail below with examples, so as to fully understand and implement the implementation process of how the present invention uses technical means to solve technical problems and achieve technical effects.

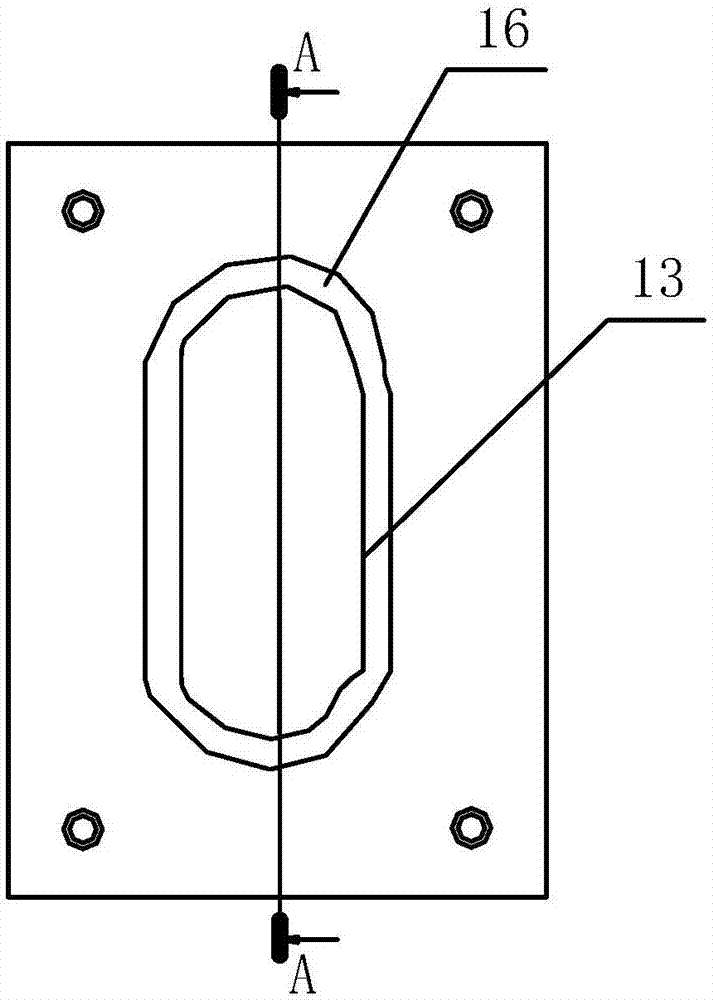

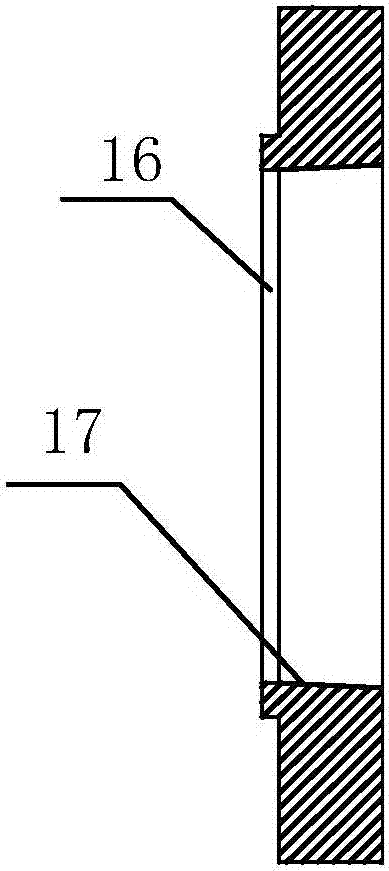

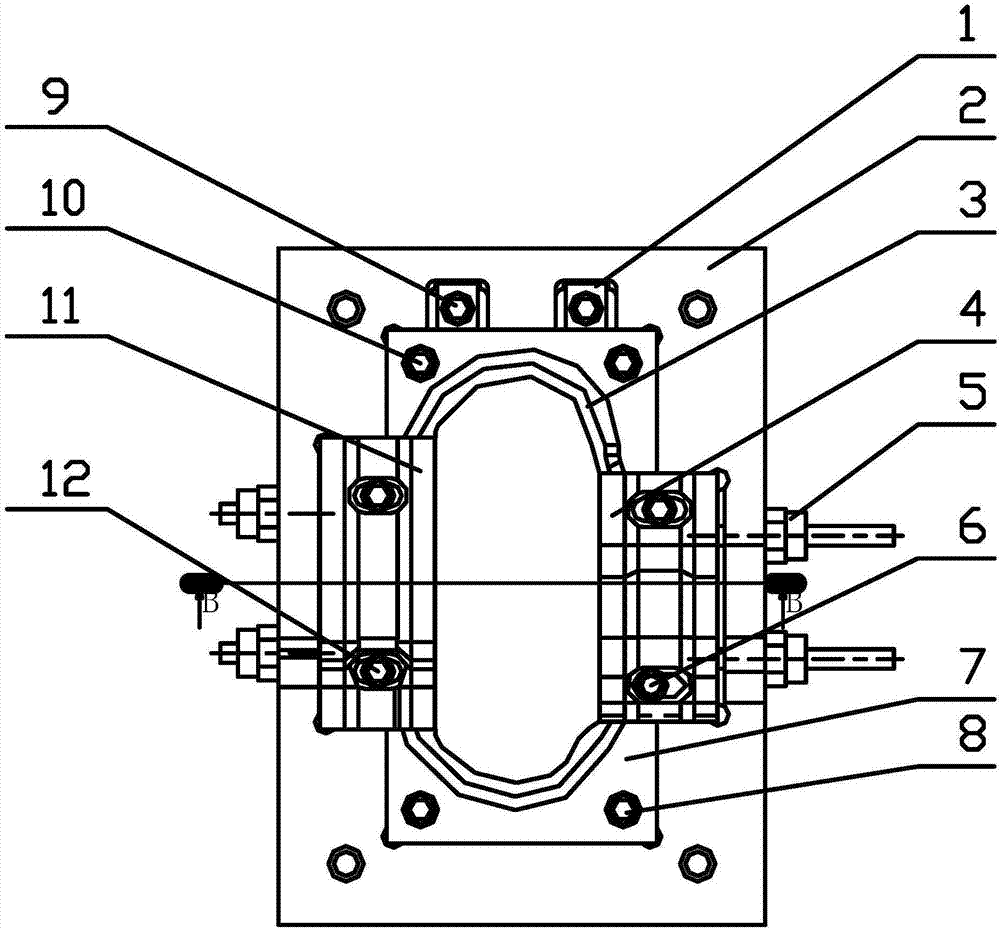

[0032] The invention discloses a chain rail joint hot cutting knife edge device, such as image 3 As shown, the assembled mold frame 2 is included, and the assembled mold frame 2 is provided with a rear blade 3, a hole surface cutter 4, a front blade 7 and a rail surface cutter 11 connected in sequence, and the rear blade 3, the hole surface cutter Knife 4, front blade 7 and rail surface blade 11 enclose closed edge of a knife 13, and the inclination of described closed edge of a knife 13 is 0 °, and described rear blade 3 outside and on assembly frame 2 are provided with blade locking block 1.

[0033] Optionally, one side of the cutting edge of the rear blade 3 and the hole surface cutter 4 is arc-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com