Method for measuring and calculating flow of water distribution port of water supply channel

A water diversion and flow technology, applied in the direction of water supply equipment, water supply equipment, water supply main pipeline, etc., can solve the problems of high cost, damage to the integrity of the physical structure of the pipeline, and achieve the effect of avoiding measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

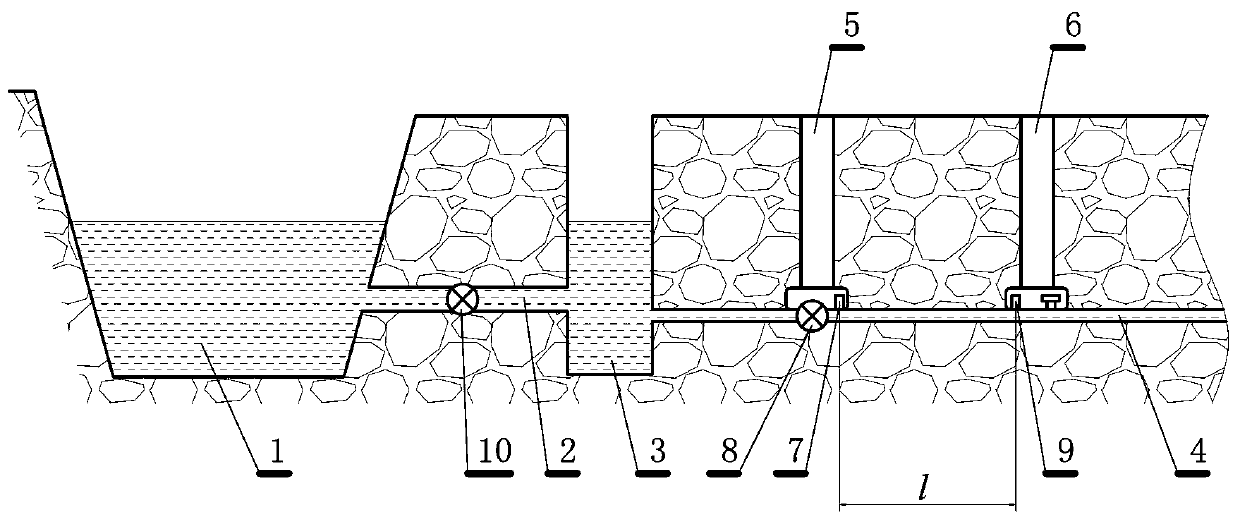

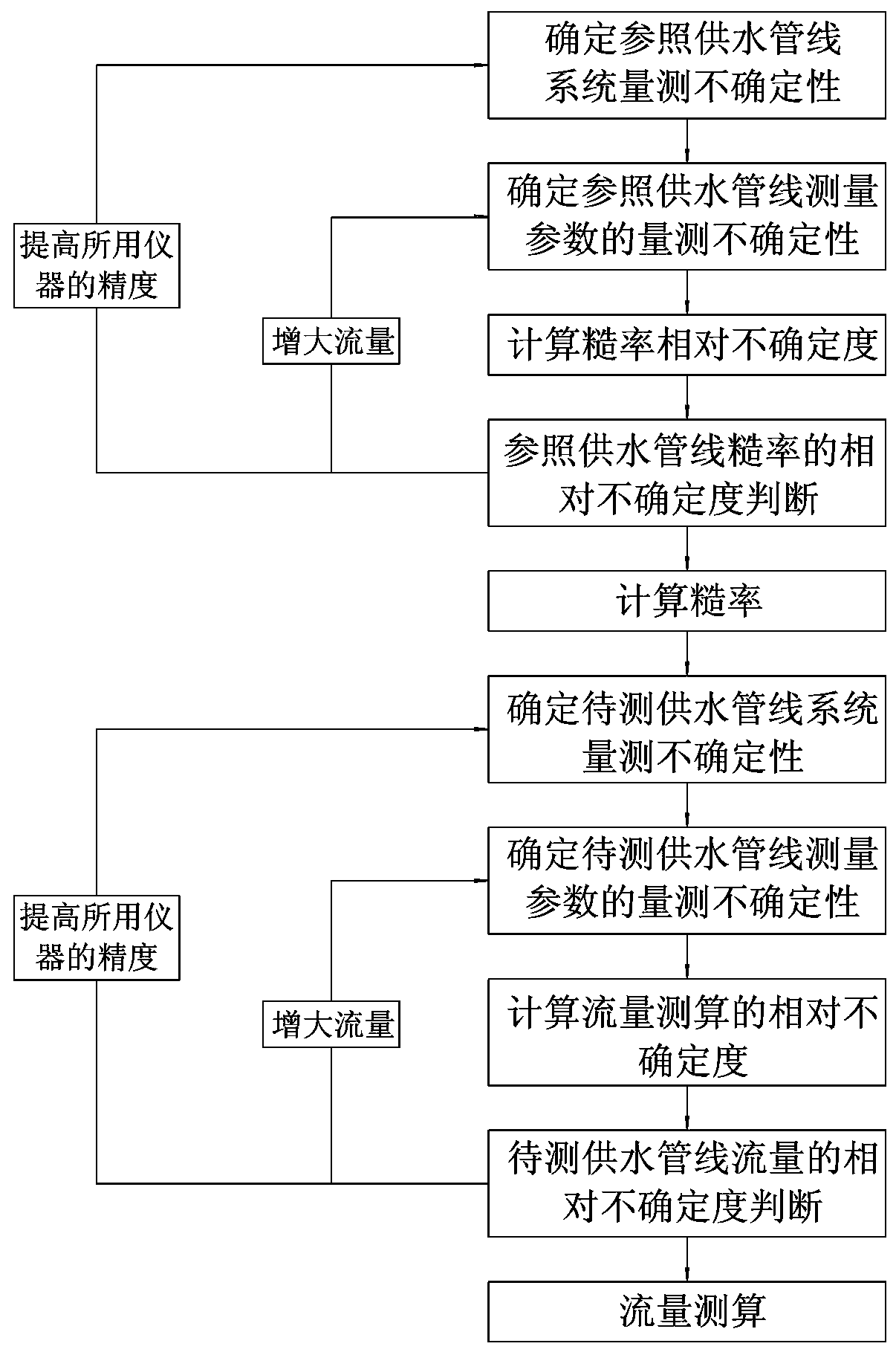

[0027] This embodiment is a method for measuring and calculating the flow rate of a water supply channel water outlet. The method uses at least one reference water supply pipeline that is the same as the water supply pipeline to be tested. The water supply channel water supply pipeline system of the water supply pipeline to be tested and the reference water supply pipeline includes : sequentially connected main canal 1, underground water delivery culvert 2, storage tank 3, water supply pipe 4, flow meter well 5 and maintenance well 6 are arranged successively along the water supply direction on the described water supply pipe, and described flow meter well is provided with Flowmeter well pressure gauge 7 and pipeline flowmeter 8, described maintenance well is provided with maintenance well pressure gauge 9, is also provided with culvert flowmeter 10 in underground water delivery culvert, as figure 1 shown.

[0028] Large-scale water supply channels have many same types of wate...

Embodiment 2

[0068] This embodiment is an improvement of the first embodiment, and is a refinement of the relative roughness uncertainty threshold of the first embodiment. The roughness relative uncertainty threshold described in this embodiment is 3-7%.

[0069] The roughness relative uncertainty threshold is generally set at about 5%, which is determined based on factors such as experience and norms. The determination of its scope should neither be too large nor too small. If it is too large, the precision will not be enough to determine the precise roughness; if it is too small, the investment in instruments and equipment will be too large, which is economically uneconomical.

Embodiment 3

[0071] This embodiment is an improvement of the first embodiment, and is a refinement of the relative uncertainty threshold of the flow rate in the first embodiment. The flow relative uncertainty threshold described in this embodiment is 3-7%.

[0072] The relative uncertainty threshold of flow rate is generally set at about 5%, which is determined based on factors such as experience and norms. The determination of its scope should neither be too large nor too small. If it is too large, the accuracy will not be enough to determine the precise flow rate, if it is too small, the investment in instruments and equipment will be too large, which is not economically cost-effective.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com