Multi-AGV scheduling method based on petri network decomposition

A scheduling method and technology for scheduling networks, which can be used in instruments, data processing applications, forecasting, etc., and can solve problems such as low operating efficiency, low response speed and low adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The present invention will be further described below in conjunction with the accompanying drawings.

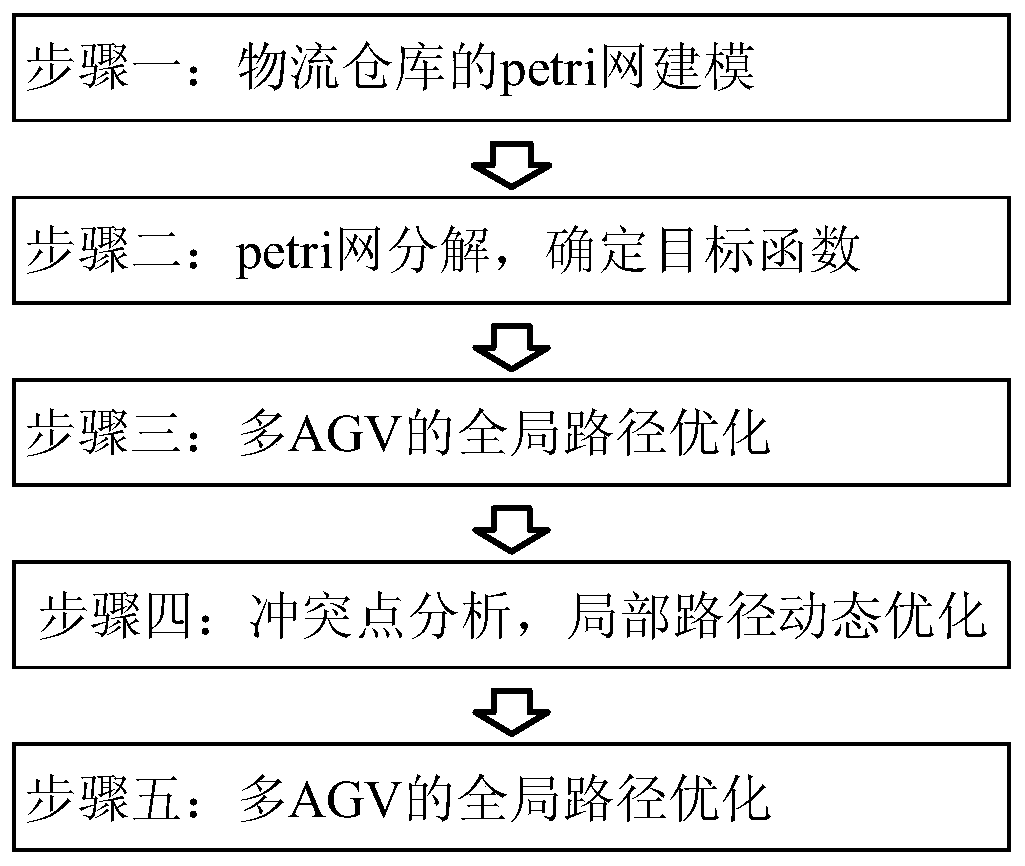

[0067] refer to figure 1 and figure 2 , a multi-AGV scheduling method based on petri net decomposition, comprising the following steps:

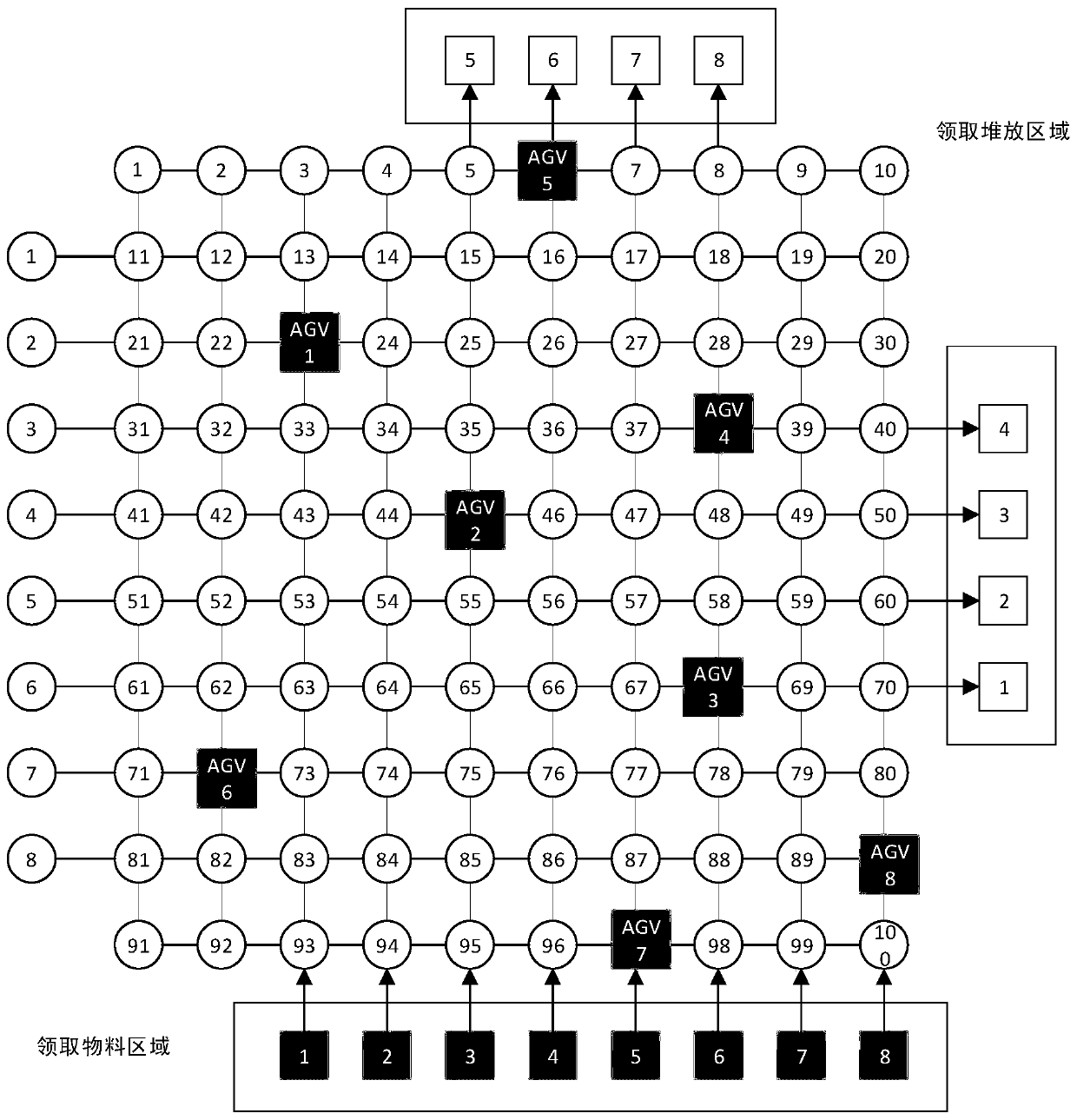

[0068] Step 1: Build an environment map to form a dispatching network model in a multi-AGV environment. The process is as follows:

[0069] 1.1: In the logistics warehouse, the AGV runs according to the pre-specified route (including one-way trajectory and two-way trajectory). First, consider the map modeling of the entire environment in which the AGV operates. The establishment of the multi-AGV warehouse scheduling environment model adopts discrete The two-dimensional directed graph is used to model the network, and the basic two-dimensional directed graph G=(V, E) is used to represent the warehouse structure. V represents the collection of warehouse nodes. On the nodes, the AGV can stop or turn , E represents the collection of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com