Small-size high-voltage-resistance electromagnetic relay

An electromagnetic relay, high withstand voltage technology, applied in the direction of electromagnetic relay, electromagnetic relay details, relays, etc., can solve problems such as circuit breakers cannot be used, fatigue breakage, product failure, etc., to improve mechanical fatigue resistance and avoid early The effect of fatigue fracture and avoiding product failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

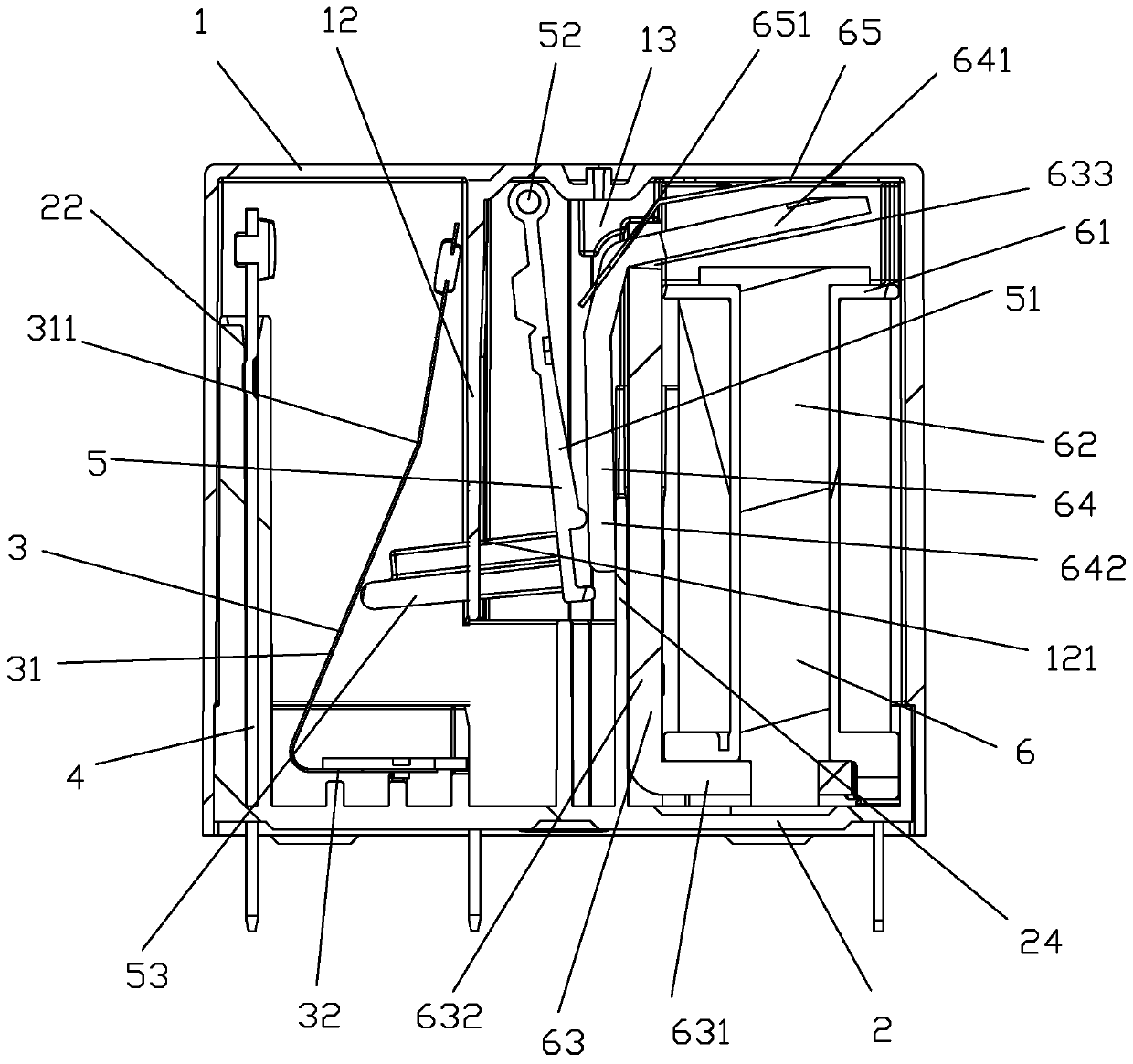

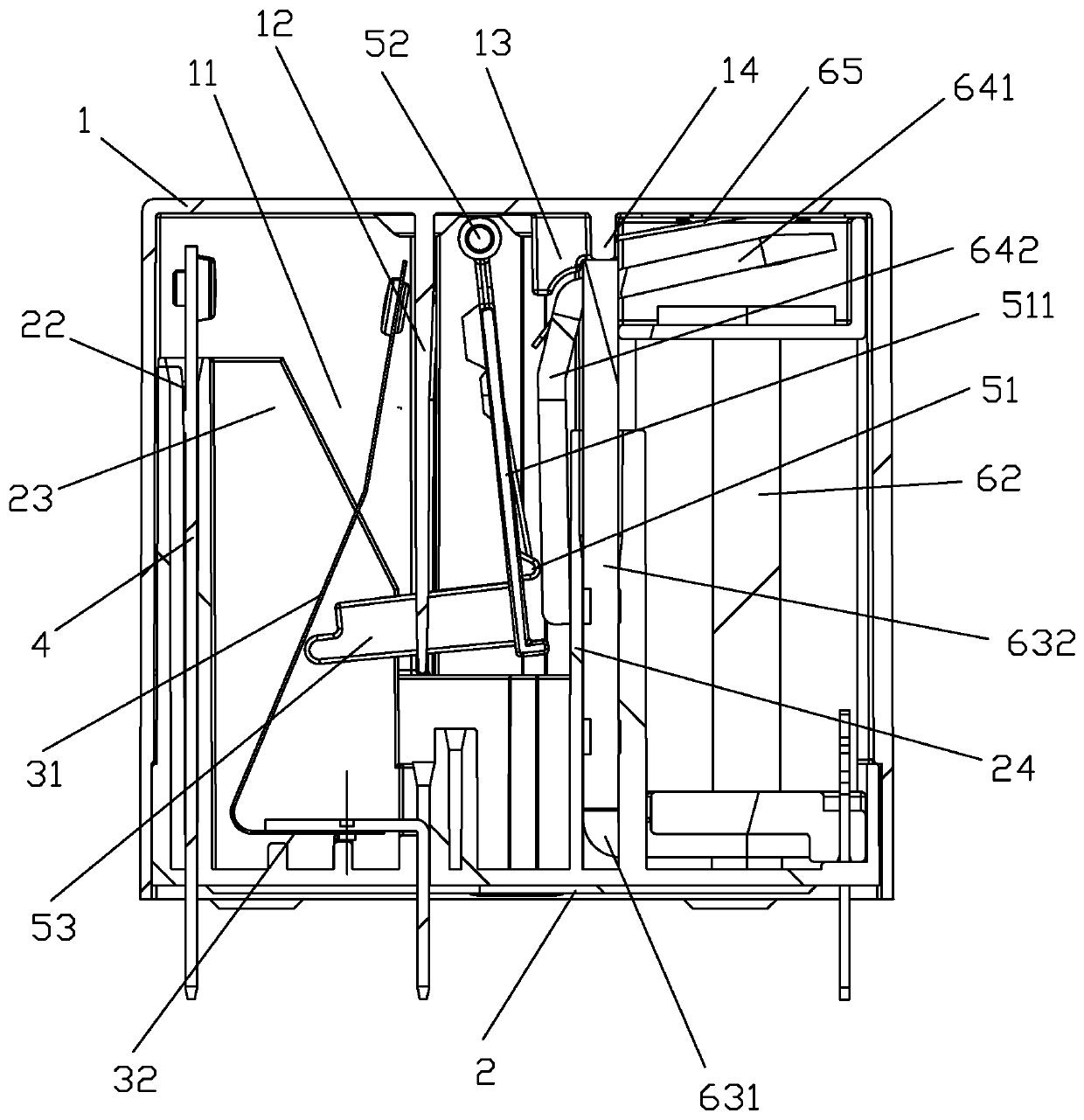

[0040] see Figure 1 to Figure 10 Shown, a kind of small volume high withstand voltage electromagnetic relay of the present invention comprises shell 1, base 2, moving reed 3, static spring 4, push card 5 and magnetic circuit part 6; Shell 1 is connected with base 2; The bottoms of the static spring 4, the moving reed 3 and the magnetic circuit part 6 are respectively installed on the base 2 and accommodated in the housing 1, and the push card 5 is fitted between the moving reed 3 and the magnetic circuit part 6; In this embodiment, the moving reed 3 is L-shaped, and the L-shaped vertical side 31 of the moving reed 3 is inclined, so as to increase the distance between the contacts and meet the requirement of disconnecting the contacts. Requirements for high pressure resistance; the L-shaped horizontal side 32 of the moving reed 3 is plugged and fixed on the base 2; ), in this embodiment, the push card 5 is L-shaped, and the top of the L-shaped vertical side 51 of the push car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com