Concrete production material yard dust fallmist spray system

A spray system and concrete technology, which are applied in the separation of dispersed particles, chemical instruments and methods, and the use of liquid separators, etc., can solve the problems of reducing the dust-reducing effect of sprinklers, and achieve the effect of convenient and simple fixing and dismantling methods, and improve the effect of dust-reducing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the drawings.

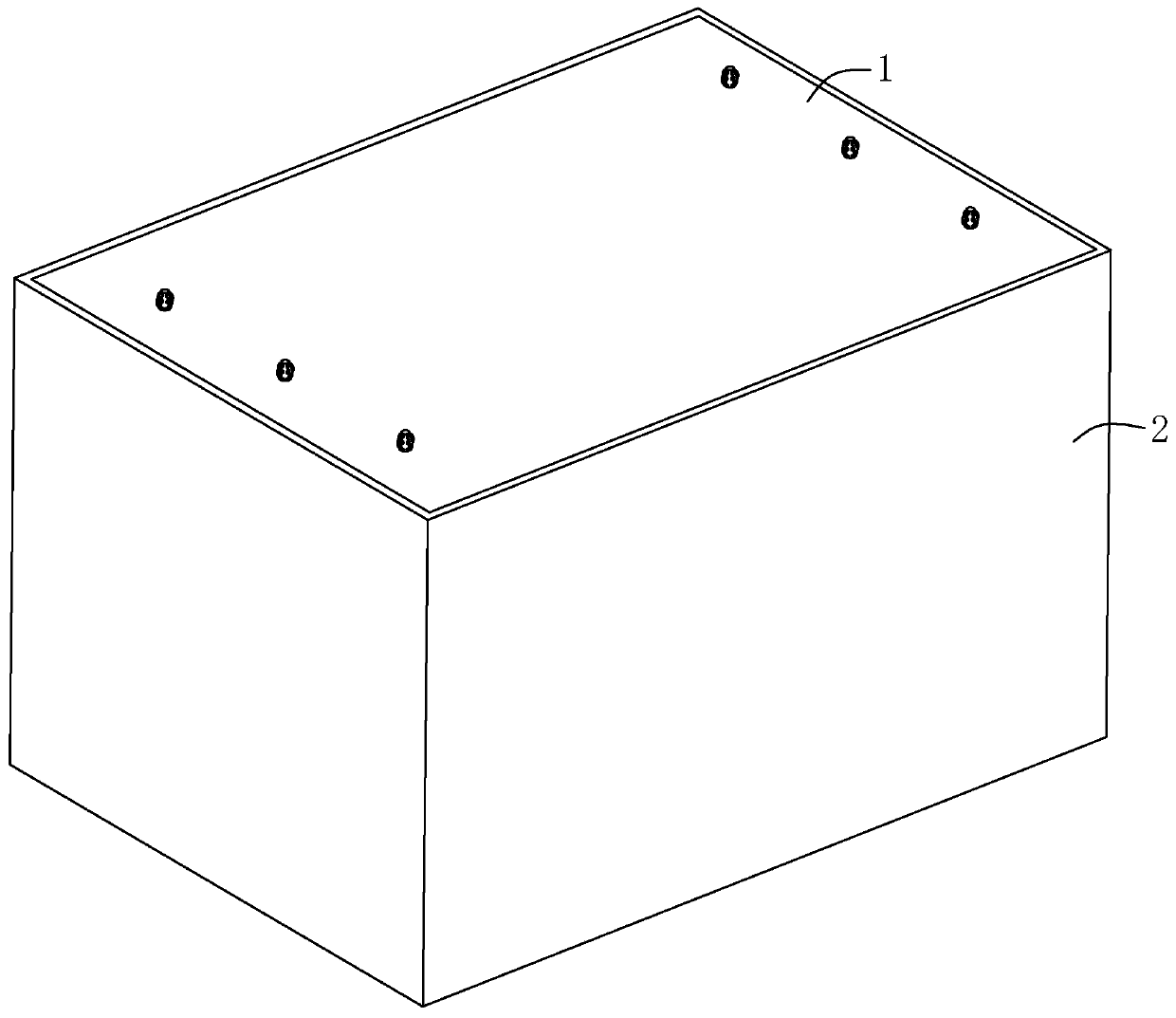

[0033] Reference figure 1 , Is a dust reduction spray system for a concrete production stockyard disclosed in the present invention, including a plant body, which includes a top plate 1 and a side plate 2, and a dust detection mechanism for detecting the dust is provided on the top plate 1.

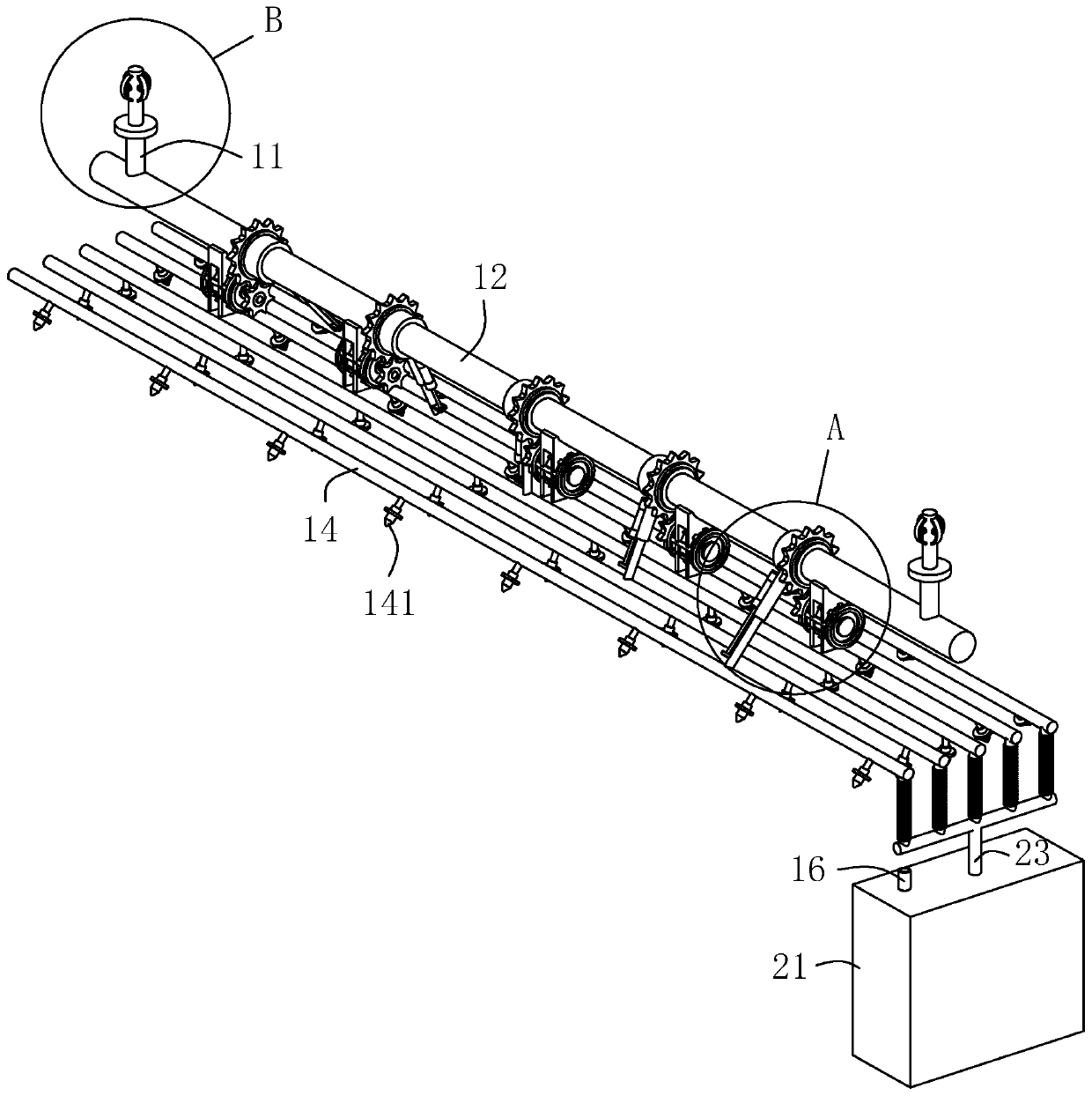

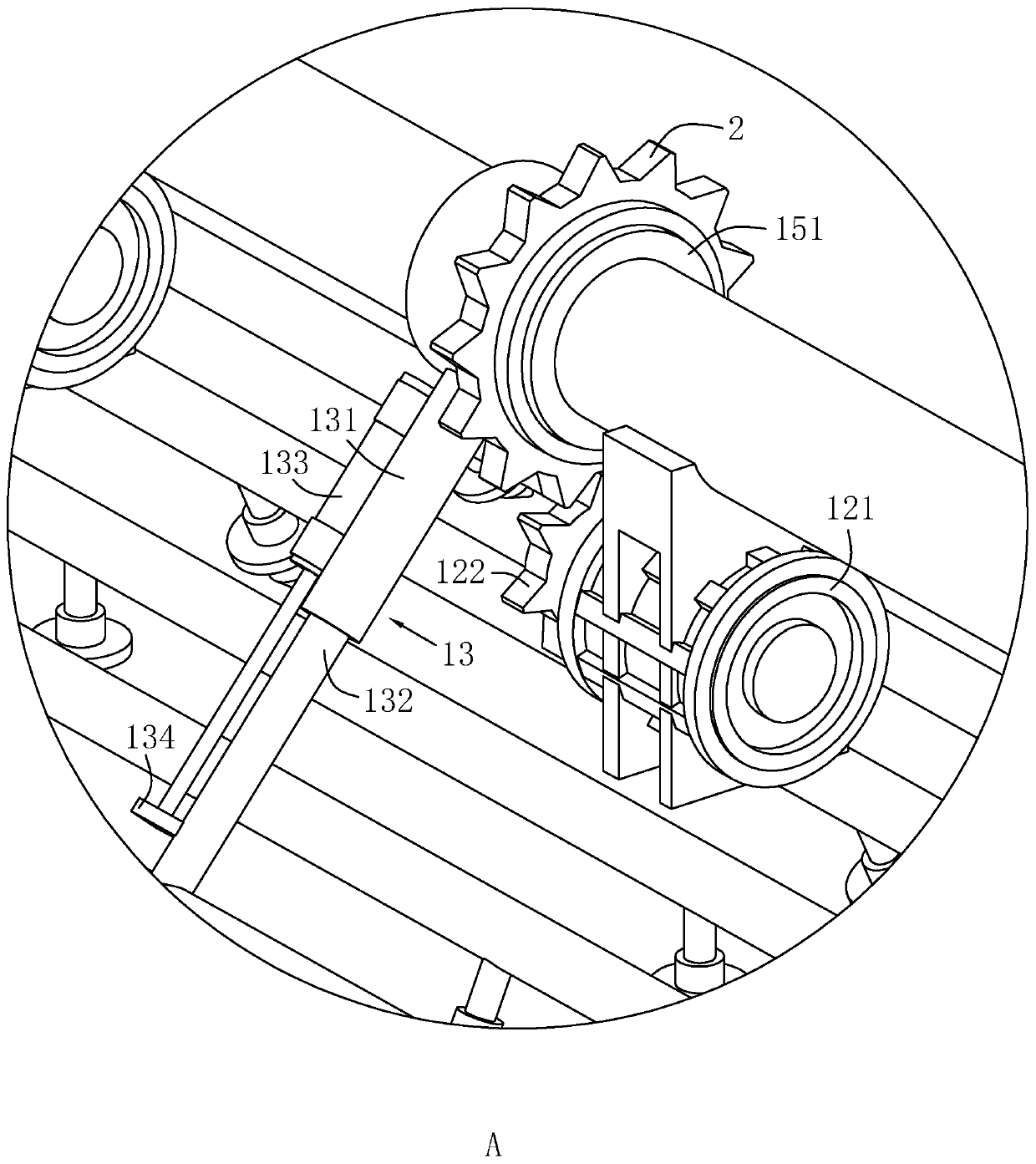

[0034] Combine figure 2 with image 3 In order to reduce dust in the plant body, a plurality of sets of dust reduction parts are provided on the top plate 1, and each group of dust reduction parts includes a fixed rod 11 connected to the top plate 1, and the end of the fixed rod 11 away from the top plate 1 is provided with a rod body 12, The rod body 12 is provided with a plurality of connecting rods 13 along the length direction of the rod body 12. The connecting rods 13 are arranged perpendicular to the rod body 12, and the plurality of connecting rods 13 are arranged in a staggered ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com