Single-layer microfluidic chip with three-dimensional focusing function

A microfluidic chip, single-layer technology, applied in laboratory utensils, laboratory containers, chemical instruments and methods, etc., can solve the problems of reduced analysis and sorting accuracy, flow channel congestion, complex structure, etc. Improve analysis or sorting accuracy, prevent flow channel blockage, and achieve the effect of three-dimensional focusing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

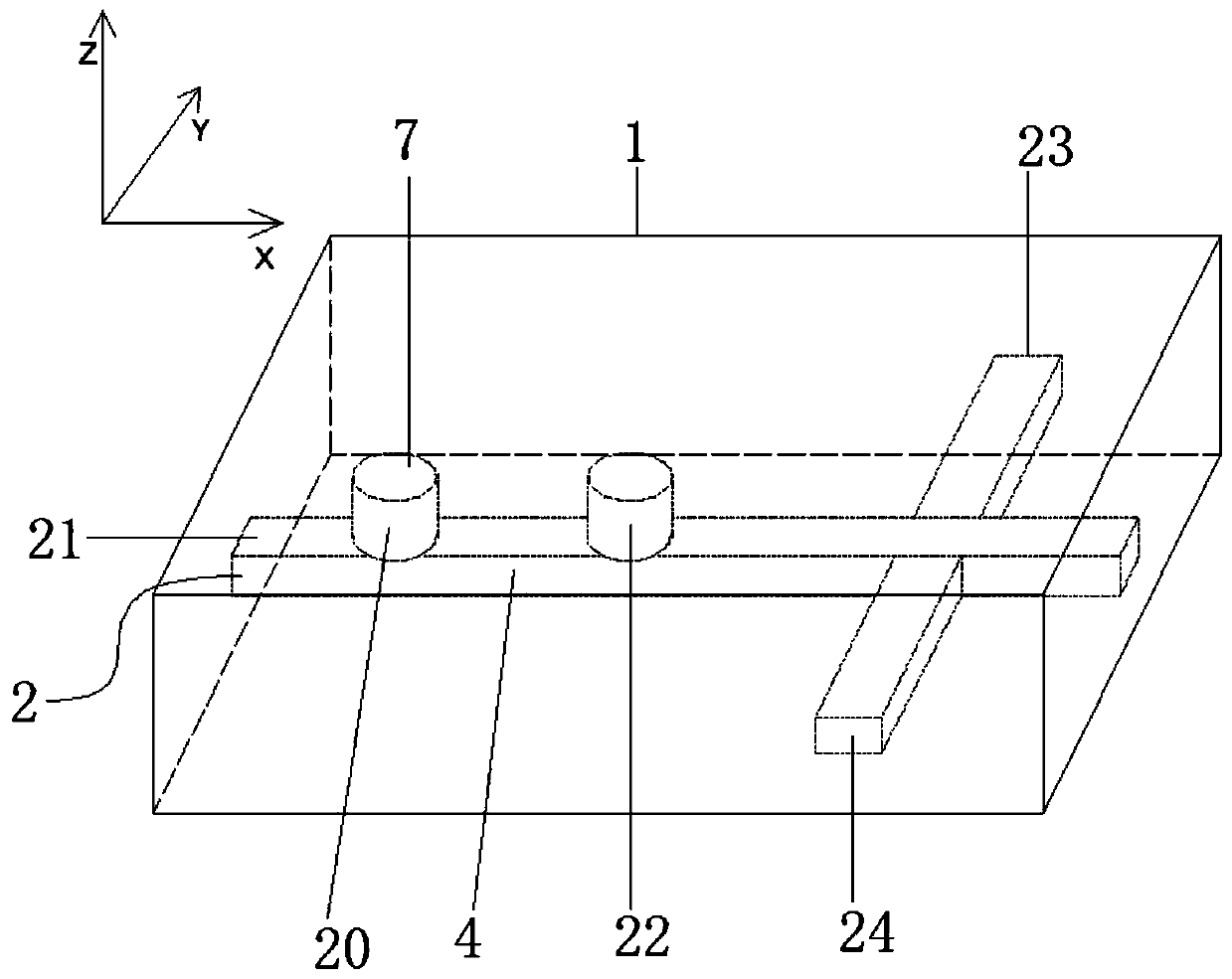

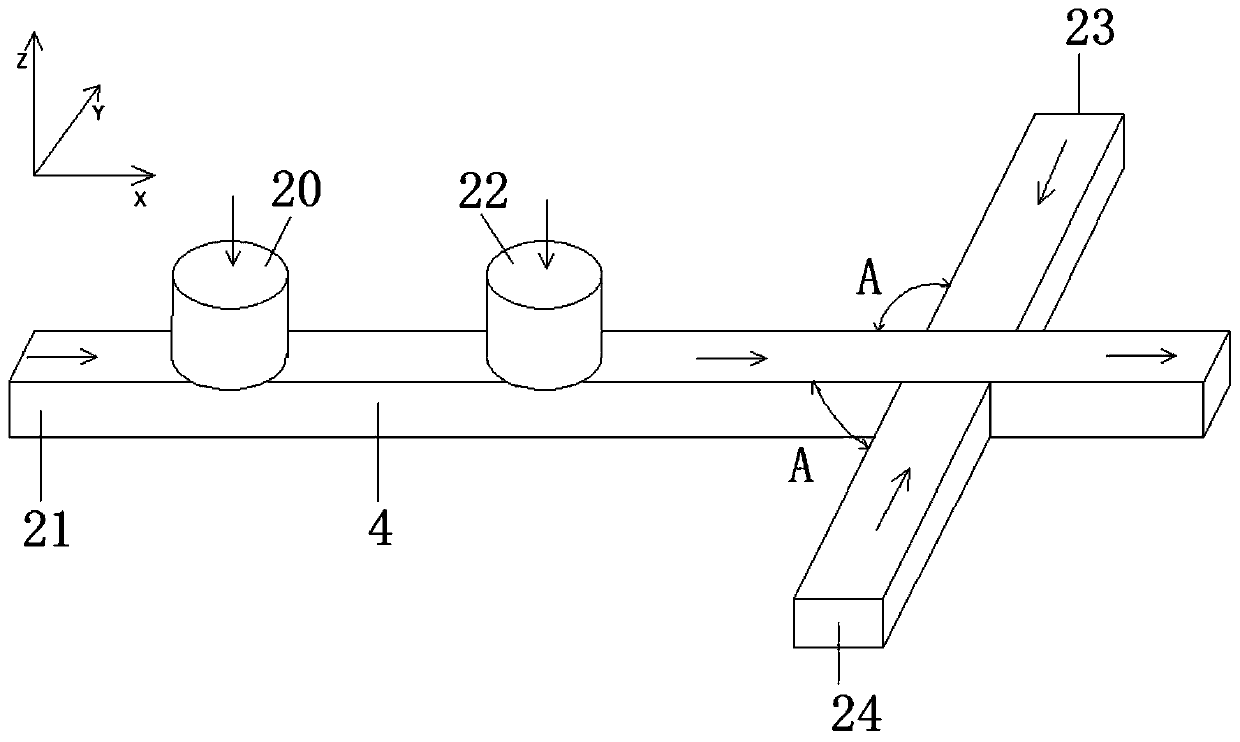

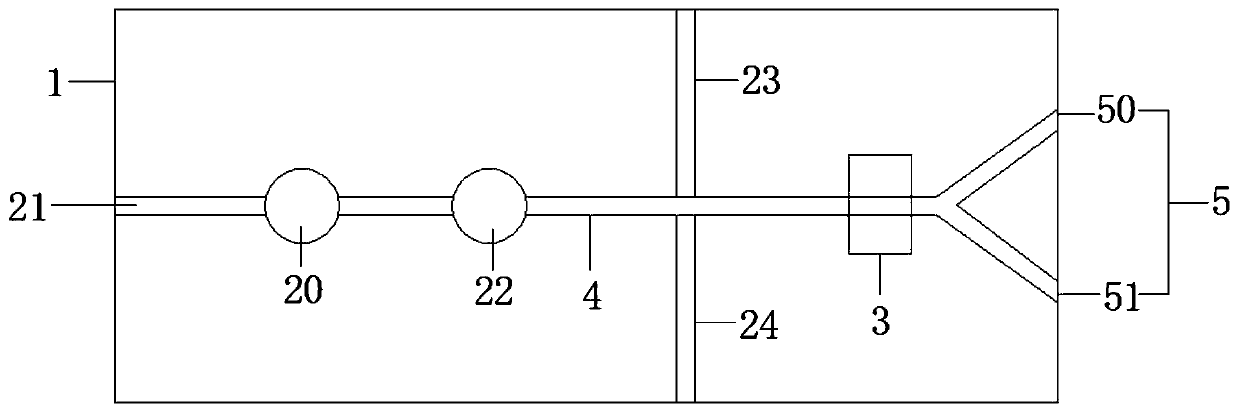

[0035] like Figure 1-2 As shown, a single-layer microfluidic chip with a three-dimensional focusing function in this embodiment includes a single-layer microfluidic chip main body 1, a main channel 4 and a focusing module 2 arranged in the single-layer microfluidic chip main body 1 , the focusing module 2 includes a sample pipeline 20 communicated with the main channel 4, and a first sheath liquid pipeline for realizing the focus of the sample flow in the main channel 4 in the vertical direction (XZ plane in the figure) communicated with the main channel 4 21 and the second sheath fluid pipeline 22, the third sheath fluid pipeline 23 and the fourth sheath fluid pipeline 23 and the fourth sheath fluid that communicate with the main channel 4 and are used to focus the sample flow in the main channel 4 in the horizontal direction (XY plane in the figure). Line 24:

[0036] The first sheath fluid pipeline 21 is on the same streamline as the main channel 4, the second sheath flui...

Embodiment 2

[0044] refer to image 3 , which is a further preferred embodiment on the basis of the above-mentioned embodiment 1, the microfluidic chip also includes a sorting module 3 arranged on the main channel 4, and after the main channel 4 passes through the sorting module 3 Two outlet channels 5 are bifurcated at the outlet end of the single-layer microfluidic chip main body 1, which are respectively a sorting channel 50 (and a target channel, which communicates with the target outlet), and a waste liquid channel 51 ( connected to the waste liquid outlet), a countercurrent sheath fluid channel 6 communicating with the main channel 4 is provided between the two outlet channels 5, and the countercurrent sheath fluid channel 6 is connected to the main channel The flow direction of the fluid in channel 4 is opposite to the reverse flow of the sheath fluid.

[0045] After the sample passes through the sorting module 3 , target particles enter the sorting channel 50 , and non-target cell...

Embodiment 3

[0048] refer to Figure 4-8 , as a further preferred embodiment on the basis of embodiment 2, a flow guide device 8 is arranged in the main channel 4 at the intersection of the two outlet channels 5, and the flow guide device 8 is located between the main channel 4 and the countercurrent sheath liquid flow The junction of the channel 6; the guide device 8 includes two guide vanes 80 connected to each other, the angle between the two guide vanes 80 is the same as the angle between the two outlet flow channels 5, and the two guide vanes 80 are the same. The flow vanes 80 are symmetrically distributed on both sides of the center line of the reverse flow sheath fluid channel 6 , and the two guide vanes 80 are respectively parallel to the two liquid outlet channels 5 . Wherein, a tapered flow guide hole 81 is vertically penetrating through the flow guide plate 80 along the thickness direction, and the size of the tapered flow guide hole 81 gradually increases from the side close to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com