Heating device and rolling device for online rolling of thick steel plate and rolling method thereof

A technology of heating device and thick steel plate, applied in rolling mill control device, workpiece heating device, metal rolling, etc., can solve the problems of billet tearing, failure to reach, damage to rolling mill, etc., achieve uniform heating, improve quality and efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

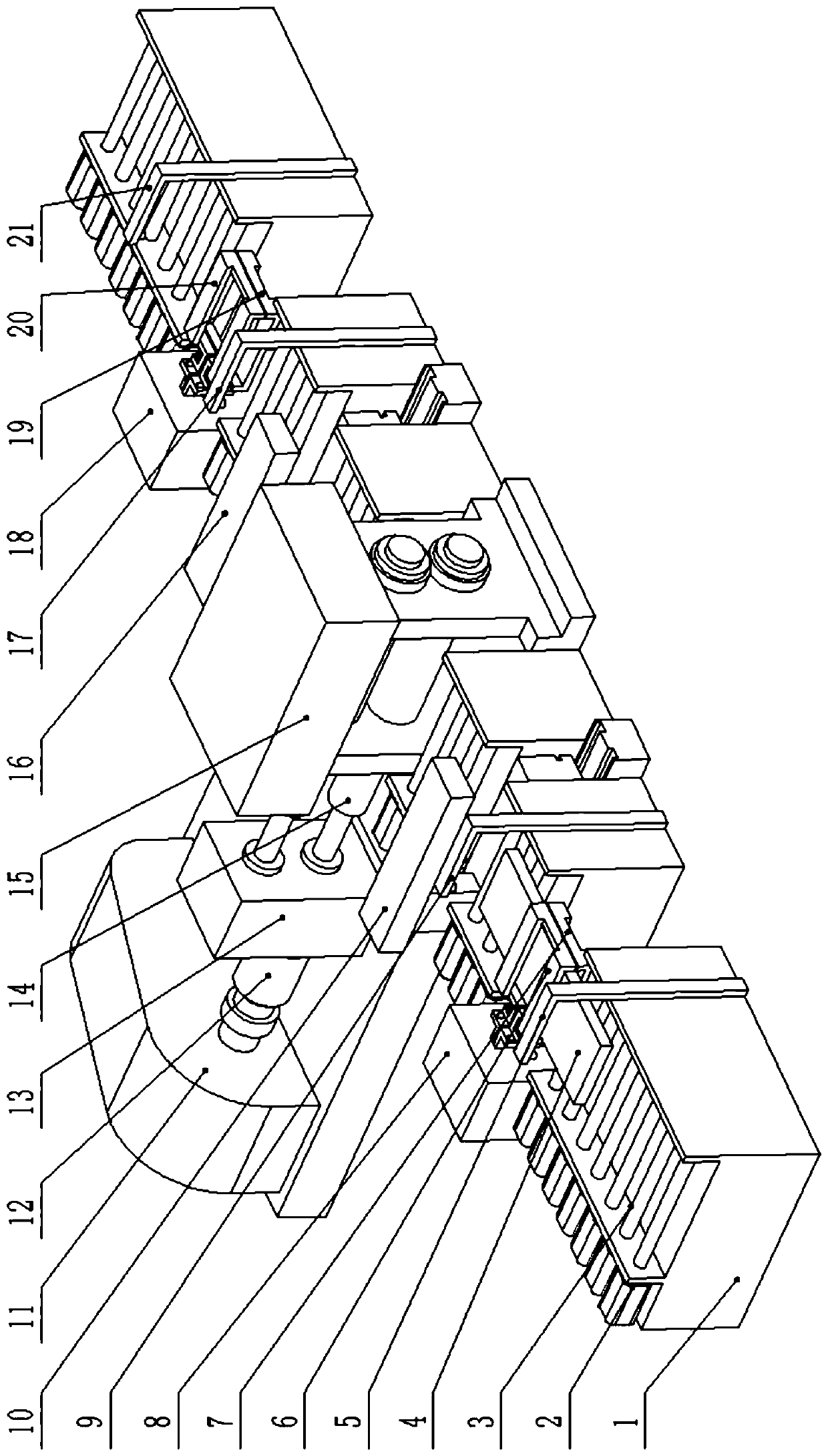

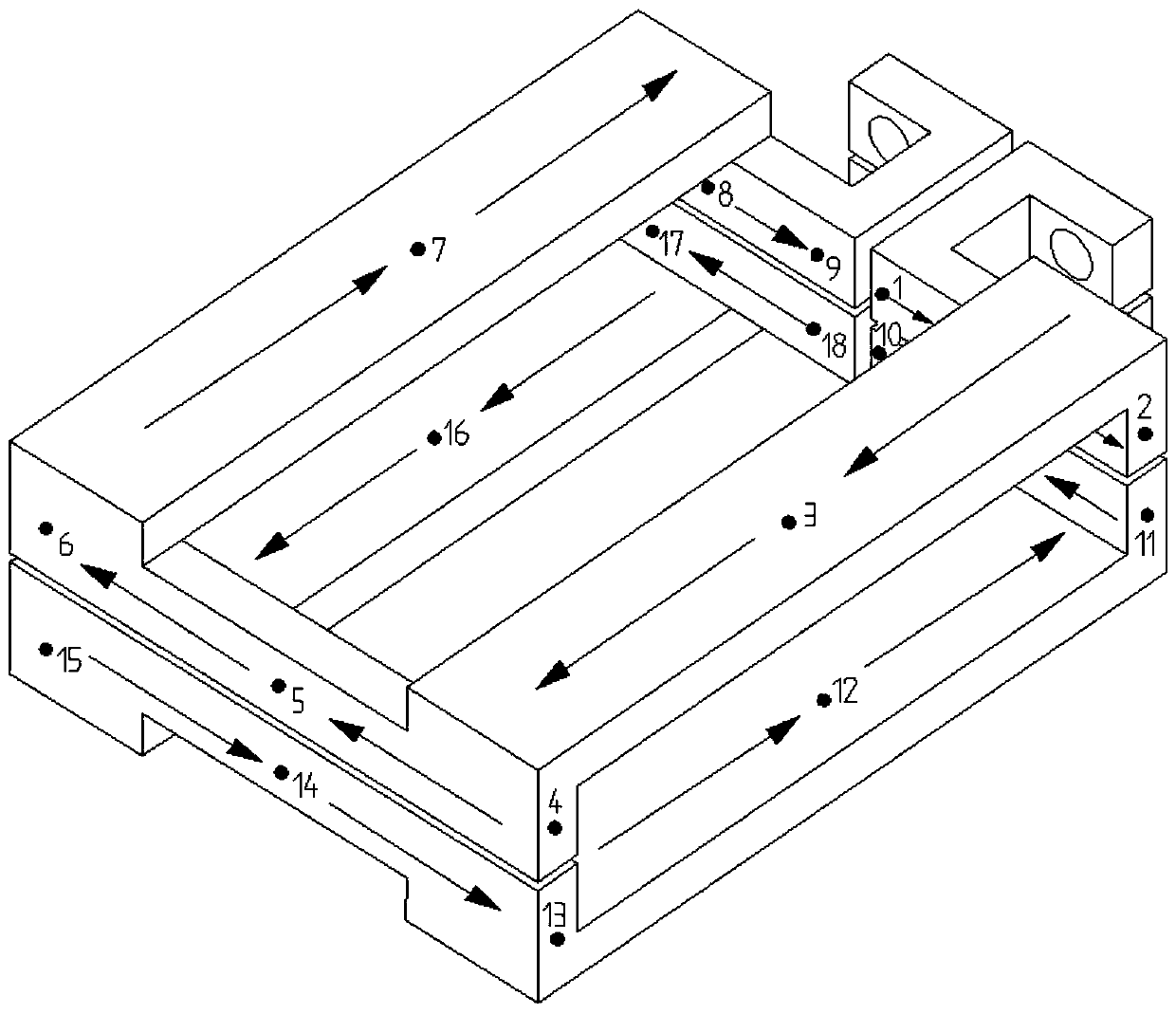

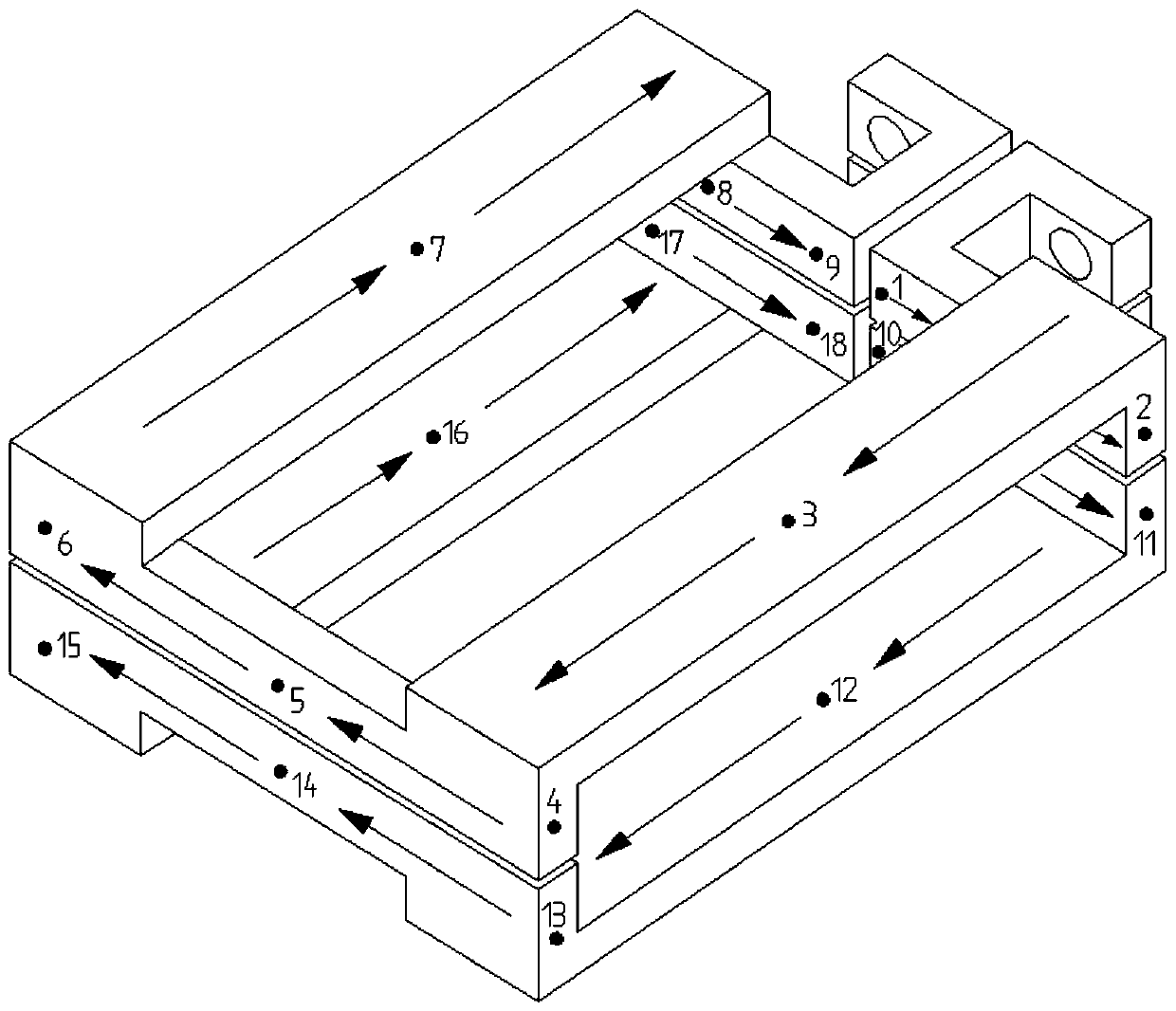

[0035] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

[0036] In the embodiment of the present invention, such as Figure 2-5 A heating device for on-line rolling of a thick steel plate is shown, which includes an AC power supply, an upper coil, and a lower coil; the upper coil is located directly above the lower coil; the left and right sides of the upper coil respectively face Bending in the direction of the lower coil, and / or the left and right sides of the lower coil are respectively bent in the direction of the upward coil; between the upper coil and the lower coil is a channel through which the thick steel plate 4 to be rolled passes; the The AC power supplies power to the upper coil and the lower coil respectively.

[0037] In the embodiment of the present invention, such as Figure 1-5 In the heating device shown, the front side of the upper coil and the front side of the lower coil form a channel outlet; the rear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com