Automotive part automatic turnover sand blasting device

A technology for auto parts and sand blasting devices, which is applied to used abrasive processing devices, abrasive jetting machine tools, abrasives, etc. It can solve the problems of affecting the ability to turn over and the inability to clamp auto parts, so as to ensure stable clamping Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

[0026] like Figure 1-Figure 6 As shown, the present invention provides a technical scheme of an auto parts automatic flip sandblasting device:

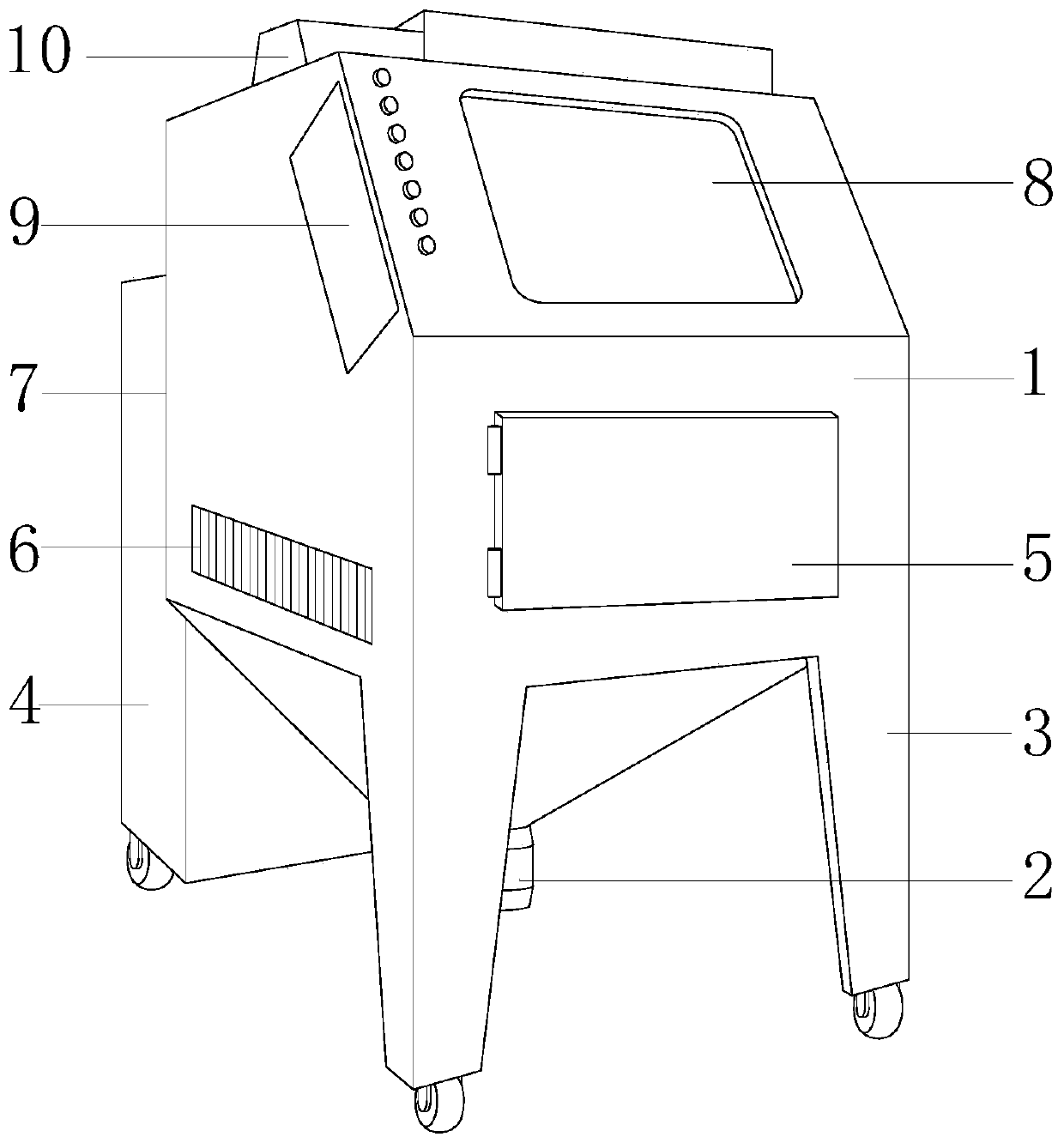

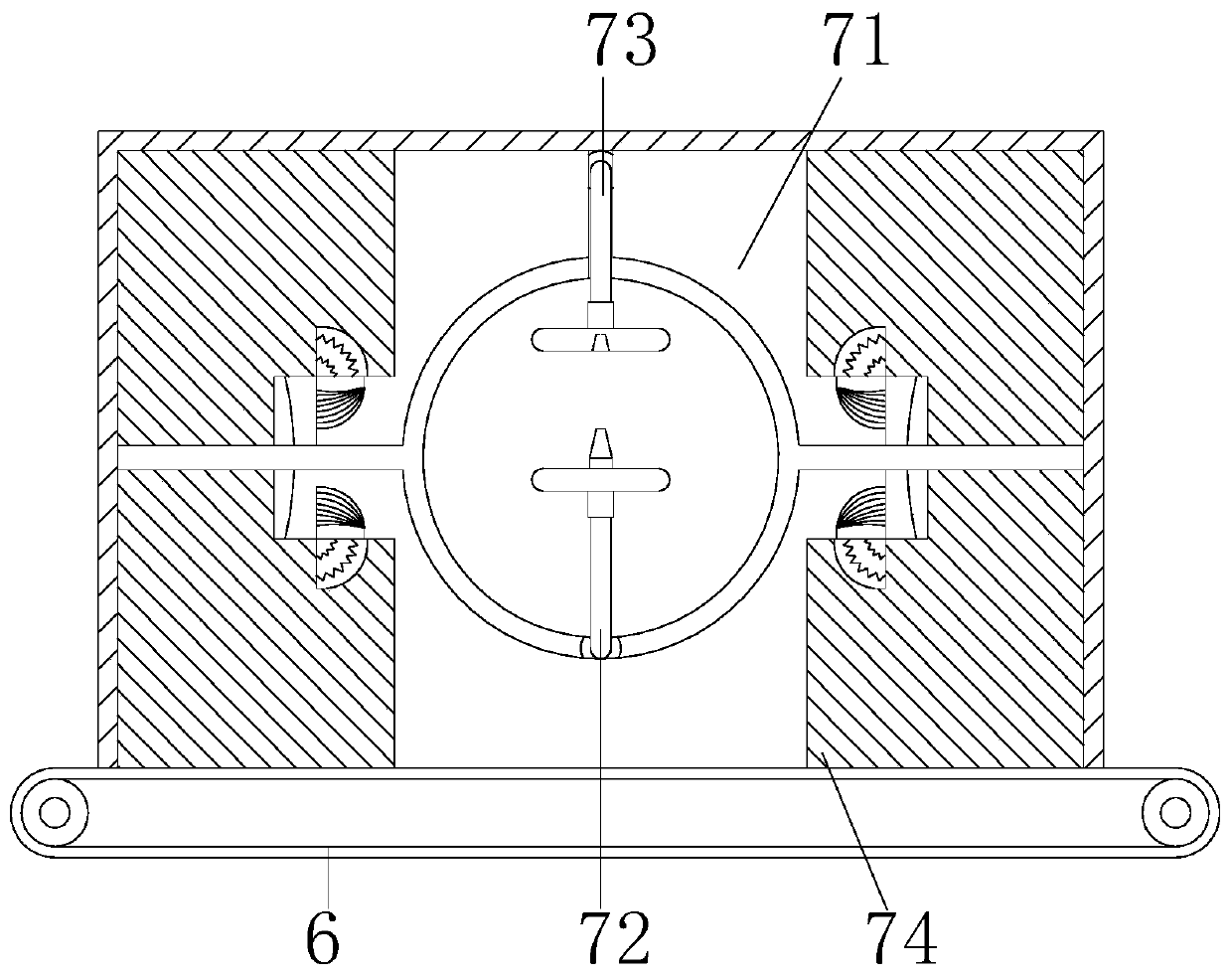

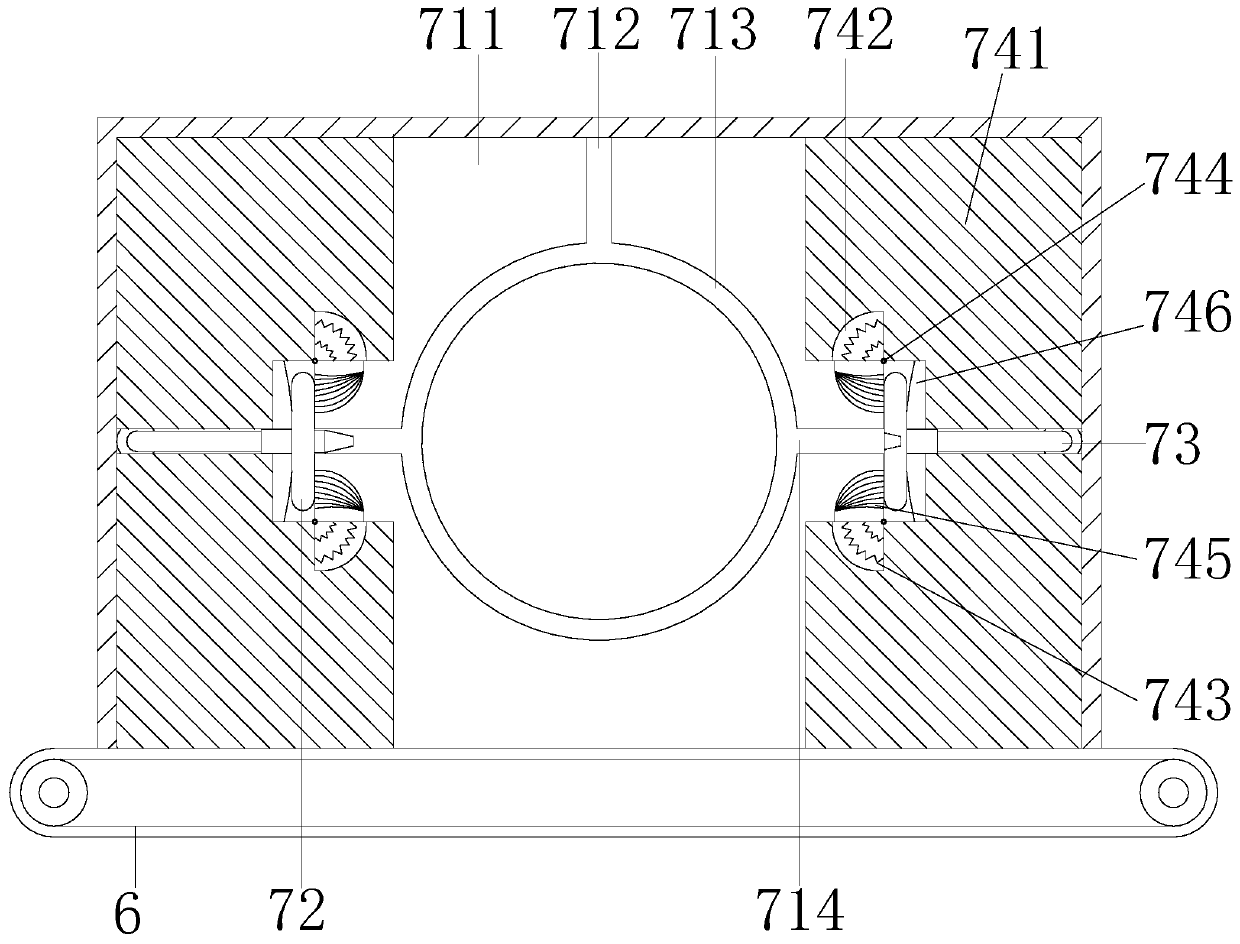

[0027] An automatic turning sandblasting device for auto parts, its structure includes a sandblasting machine body 1, a recovery bucket 2, a support foot 3, a raw material box 4, an accessory inlet 5, an accessory output device 6, an intermittent self-removing sand turning device 7, Visible window 8, electric control box 9, exhaust gas treatment device 10, the sandblasting machine body 1 has a rectangular structure, the recovery bucket 2 is arranged under the sandblasting machine body 1 and is an integrated structure, and the supporting feet 3 are set At the four ends below the sandblasting body 1, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com