A light bulb automatic drying device

A technology of drying device and light bulb, applied in drying, dryer, progressive dryer and other directions, can solve the problems of personal injury, increase labor cost and time cost, low efficiency of manual operation, etc. The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

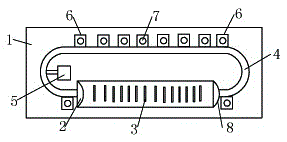

[0010] Combine below figure 1 Specific description embodiment:

[0011] Such as figure 1 As shown, an automatic bulb drying device includes a frame 1, the frame 1 is provided with a drying channel 2, the bottom of the drying channel 2 is a heating wire 3, and the frame 1 is provided with There is an endless conveying chain 4, and the said endless conveying chain 4 is connected with a motor 5, and said endless conveying chain 4 is provided with a plurality of bulb fixing seats 6, and said bulb fixing seats 6 are provided with seat holes 7, said The endless conveyor chain 4 partially passes through the drying tunnel 2 and is located above the heating wire 3 . The said drying tunnel 2 is provided with an arched shield 8 .

[0012] In actual use, the light socket of the light bulb passes downwards through the seat hole on the light bulb fixing seat and is placed on the endless conveyor chain. The endless conveyor chain drives the bulbs to perform circular motion. The circular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com