A mechanical arm for handcart cargo loading and unloading

A technology of mechanical arms and trolleys, applied in the field of mechanical arms for loading and unloading goods with manual trolleys, can solve problems such as increased costs, increased handling time, and inapplicability to market demand, so as to avoid safety accidents, speed up loading and unloading efficiency, and liberate labor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

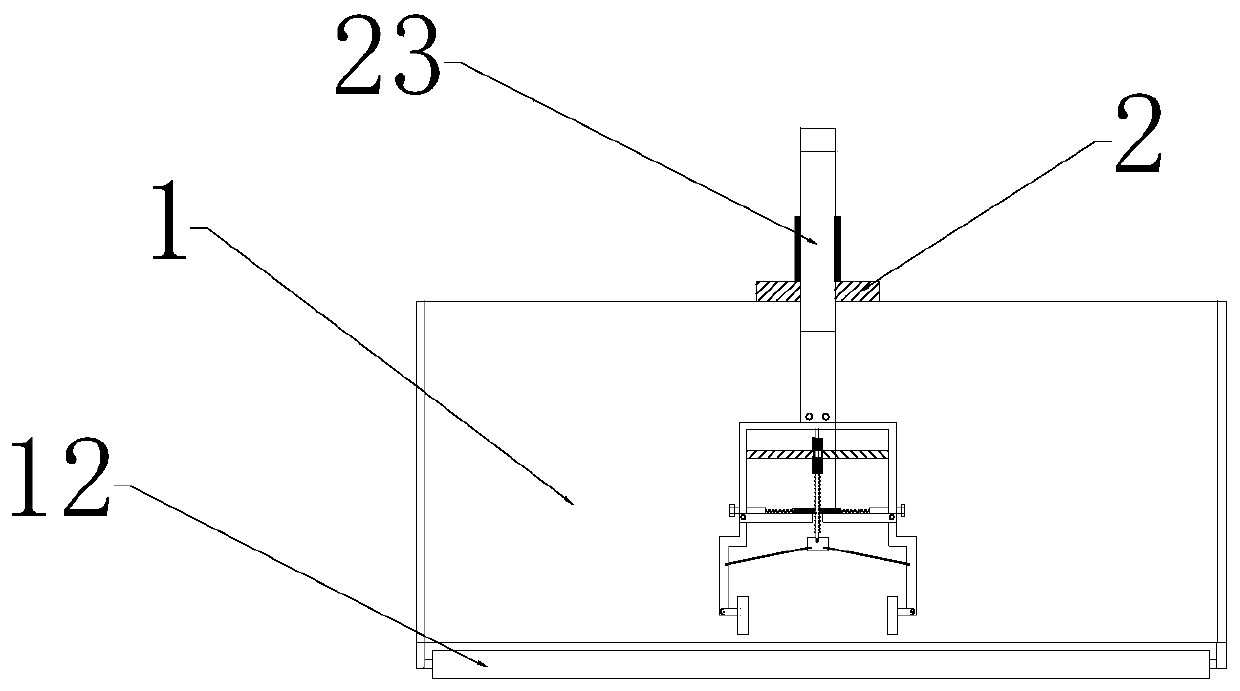

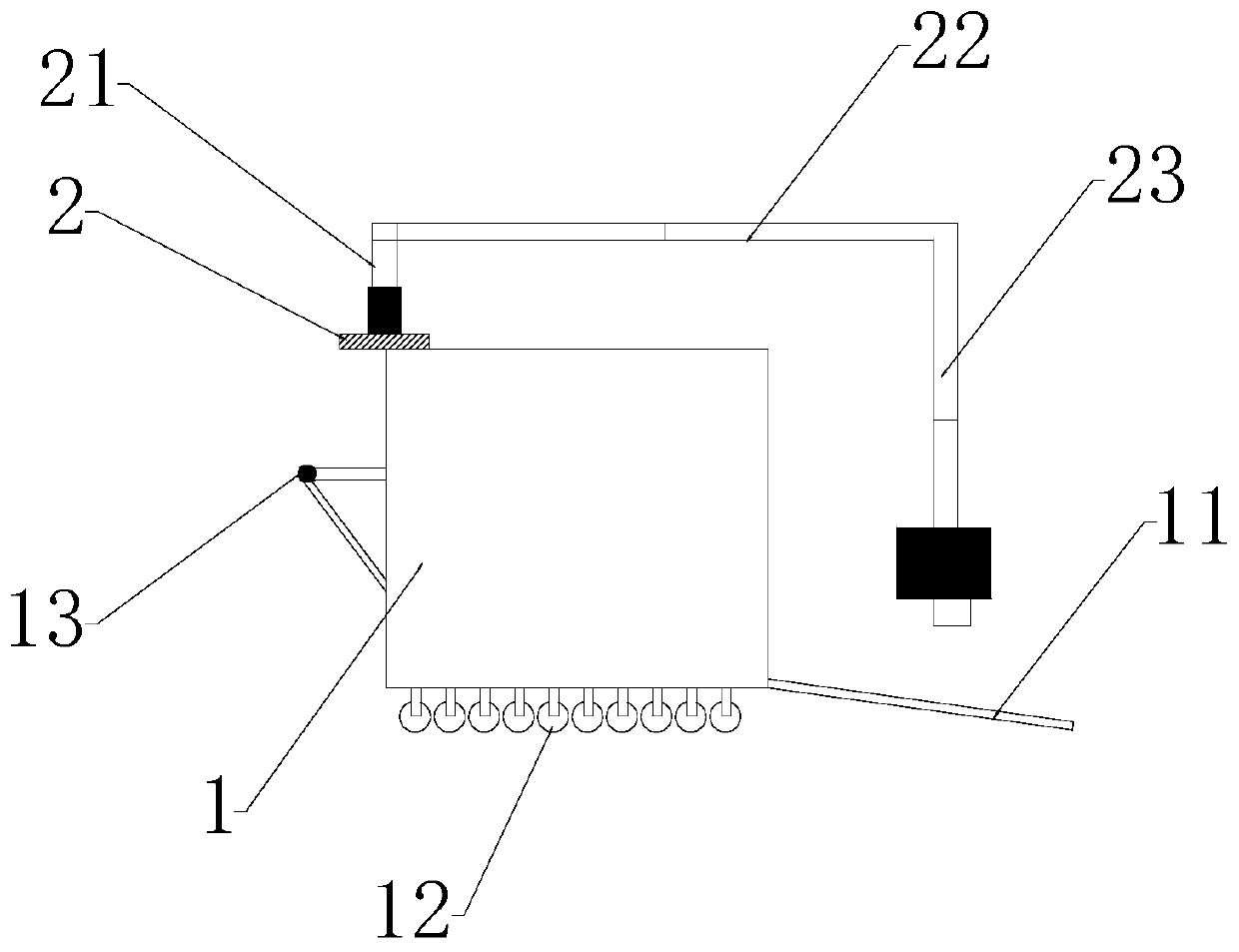

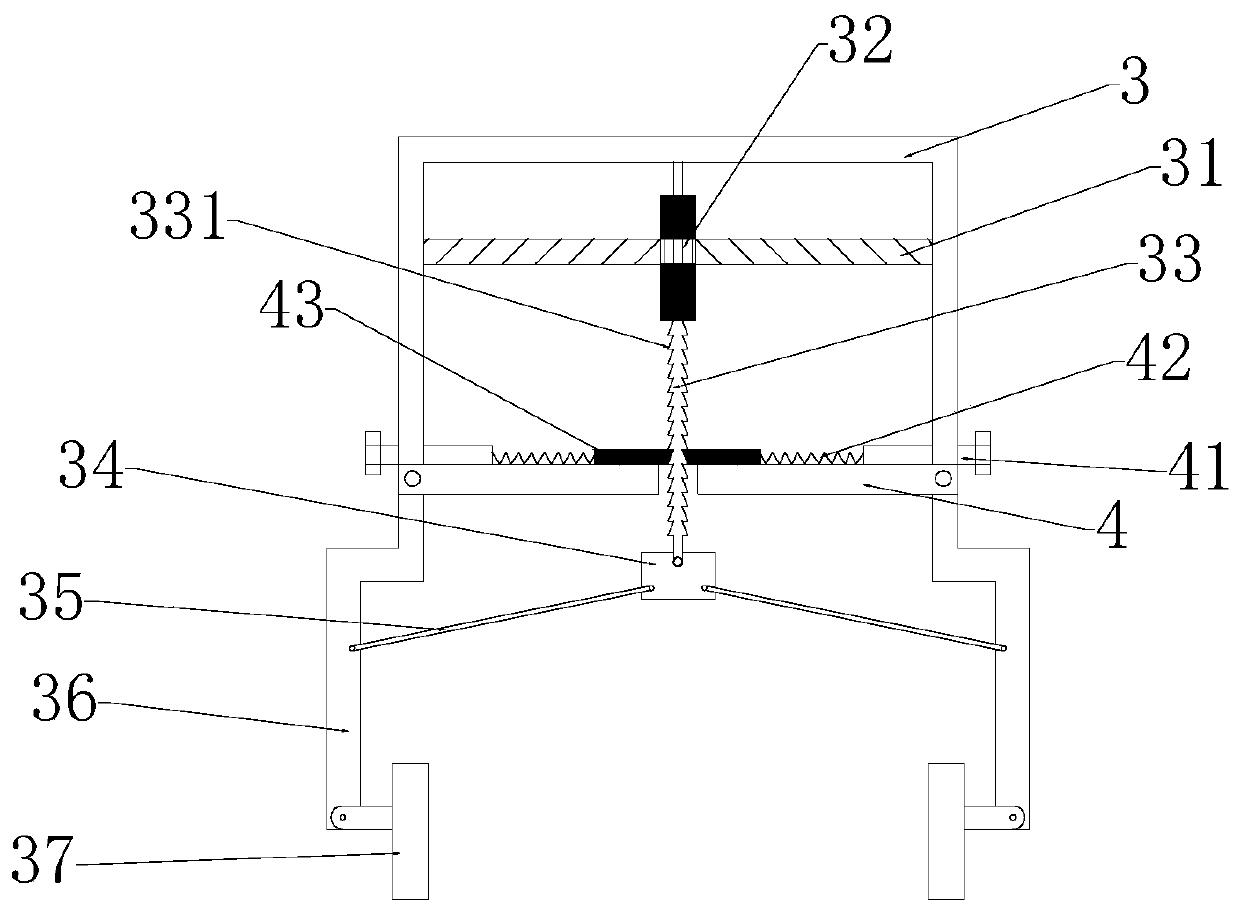

[0023] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 side view, image 3 It is a schematic diagram of the clamping assembly of the present invention, Figure 4 It is a schematic diagram of the trolley body of the present invention, Figure 5 It is a combined schematic diagram of the anti-retraction block of the present invention, Figure 6 It is a schematic diagram of the separation of the anti-retraction block of the present invention. As shown in the figure, the mechanical arm for loading and unloading the manual trolley in this embodiment includes a trolley body 1, a mechanical arm assembly installed on the trolley body 1, and a mechanical arm assembly installed on the trolley body 1. The clamping assembly at the end and the auxiliary clamping assembly maintain a stable clamping safety assembly; the mechanical arm assembly includes an arm base 2 arranged on the trolley body 1 for installing a mechanical arm, and the mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com