An unloading device for a transport vehicle

A technology of unloading device and transport vehicle, which is applied in the direction of transportation and packaging, conveyor, loading/unloading, etc. It can solve the problems of heavy load, inconvenient sand unloading, and slow sand unloading by manpower, so as to achieve small load, not easy to damage, low noise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

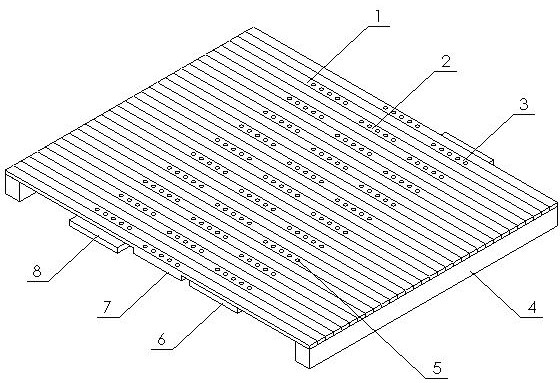

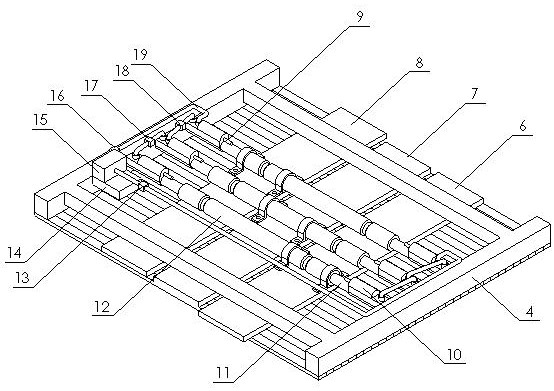

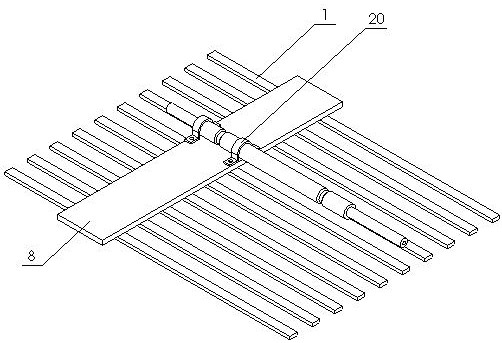

[0023]A cargo unloading device for a transport vehicle of the present invention is realized in the following way: a cargo unloading device for a transport vehicle of the present invention comprises a bottom fixed frame (4), a sliding bottom plate and push-pull parts, and the sliding bottom plate is movably placed on the bottom fixed frame (4). ), the push-pull part is placed at the bottom of the sliding floor, the bottom fixing frame (4) is composed of two vertical bars and two horizontal bars, the two horizontal bars are placed between the two vertical bars, and the horizontal bar The two ends of the rod are vertically connected with two vertical rods respectively. The sliding bottom plate includes the No. 1 sliding bottom plate, the No. 2 sliding bottom plate and the No. 3 sliding bottom plate. The No. 1 sliding bottom plate is composed of the No. (8), the No. 2 sliding bottom plate is composed of the No. 2 slide rail (2) and the No. 2 fixed bottom plate (7), and the No. 3 sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com