Asphalt Pavement reclaim device and method

A technology for asphalt mixture and recycling equipment, applied in roads, road repair, roads, etc., can solve the problems of fuel and power consumption, high exhaust gas emissions, high energy consumption, etc., to reduce emissions and odors, save energy, and improve materials. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

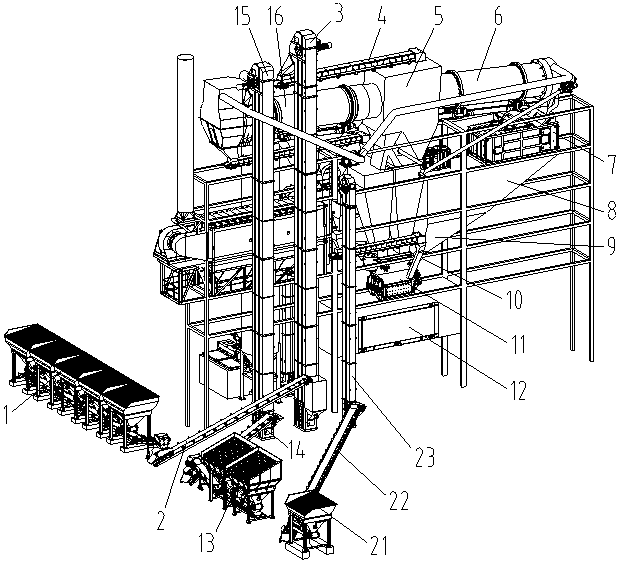

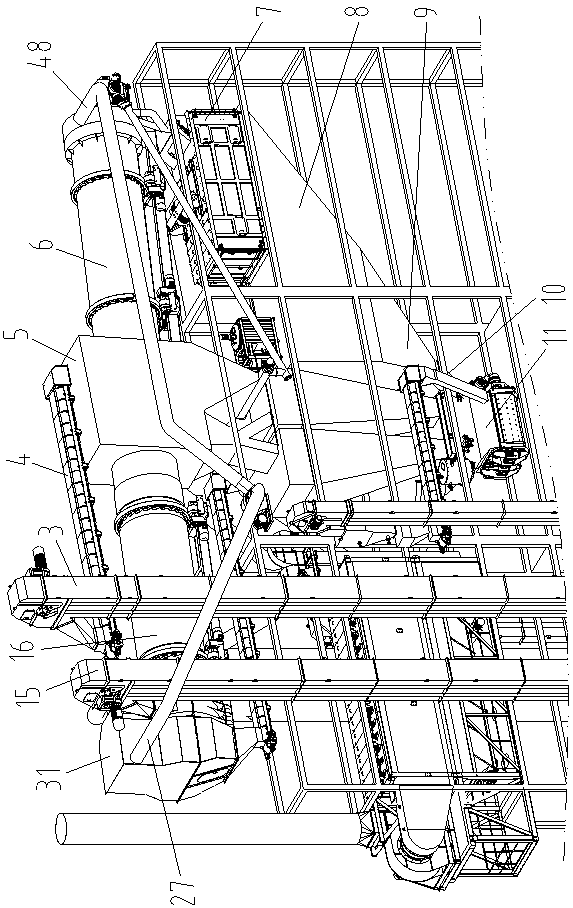

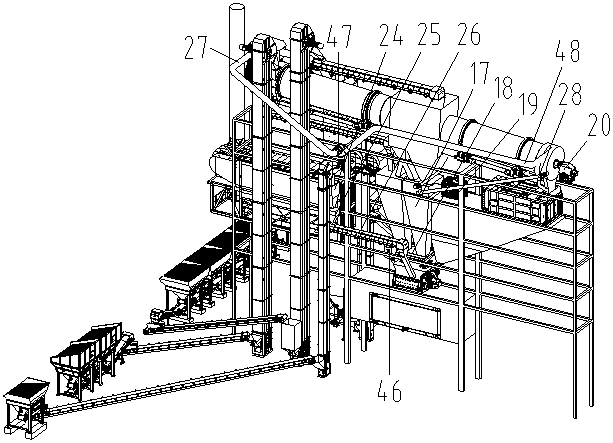

[0042] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments will be described in detail with reference to the accompanying drawings.

[0043] Such as Figure 1 to Figure 7 As shown, this embodiment provides a kind of asphalt mixture recycling equipment, including the original drying drum 6 and the regeneration drying drum 16, and the original drying drum 6 and the regeneration drying drum 16 are respectively installed obliquely on the upper part of the main building, The lower end of the primary drying drum 6 is equipped with a burner 20 shared with the regenerated drying drum 16, and the higher end of the primary drying drum 6 is opposite to the lower end of the regenerated drying drum 16 and between the two A transition chamber 5 is connected between them, and the lower part of the transition chamber 5 is provided with two discharge passages located below the lower end of the regenerativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com