Production profile monitoring method based on distributed optical fiber sound monitoring and distributed optical fiber temperature monitoring

A distributed optical fiber and profile monitoring technology, applied to thermometers, thermometers with physical/chemical changes, measurement, etc., can solve problems such as long test time, high test cost, and low test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

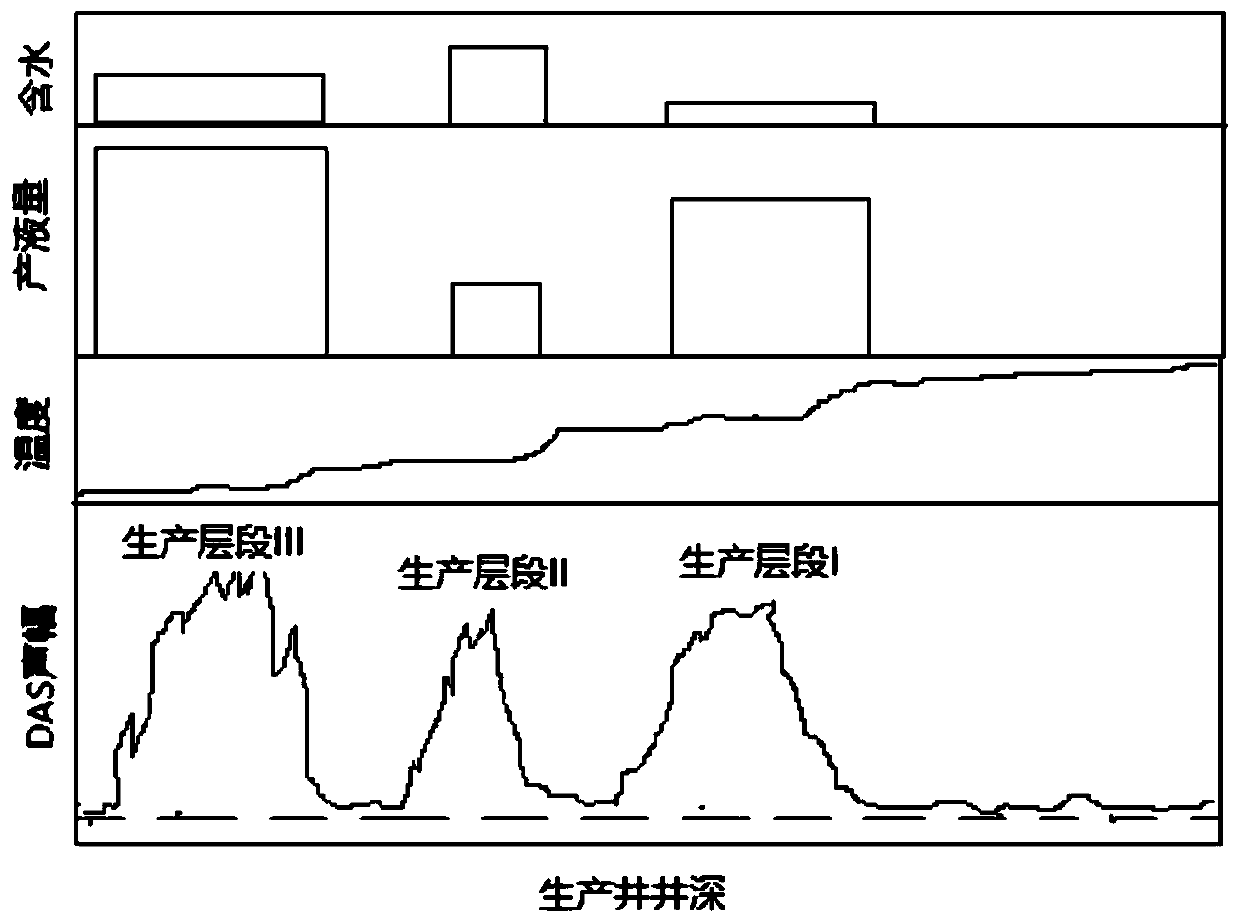

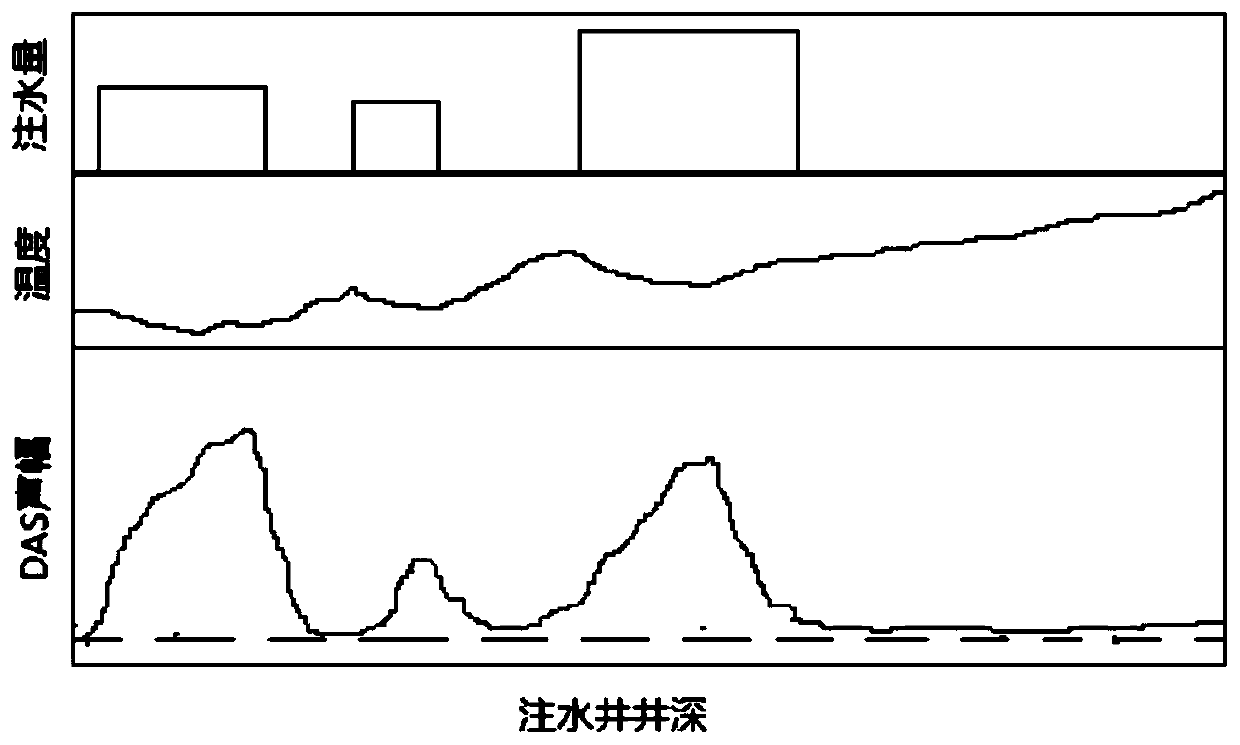

[0058] A production profile monitoring method based on distributed optical fiber sound monitoring and distributed optical fiber temperature monitoring, characterized in that the sound signal reflected by the single-mode acoustic optical fiber and the temperature signal reflected by the multi-mode temperature-sensitive optical fiber are used DTS / DAS The injection-production well production section interpretation module processes it, and finally obtains the real-time flow rate and water content of each production layer of the injection-production well.

[0059] The DTS / DAS injection-production well production profile interpretation module includes a data preprocessing module, an oil and gas well fluid production profile interpretation module and an injection well injection profile interpretation module;

[0060] The data preprocessing module is used to obtain denoised sound data and temperature data related to the flow of formation fluid into the wellbore or the flow of injected ...

Embodiment 2

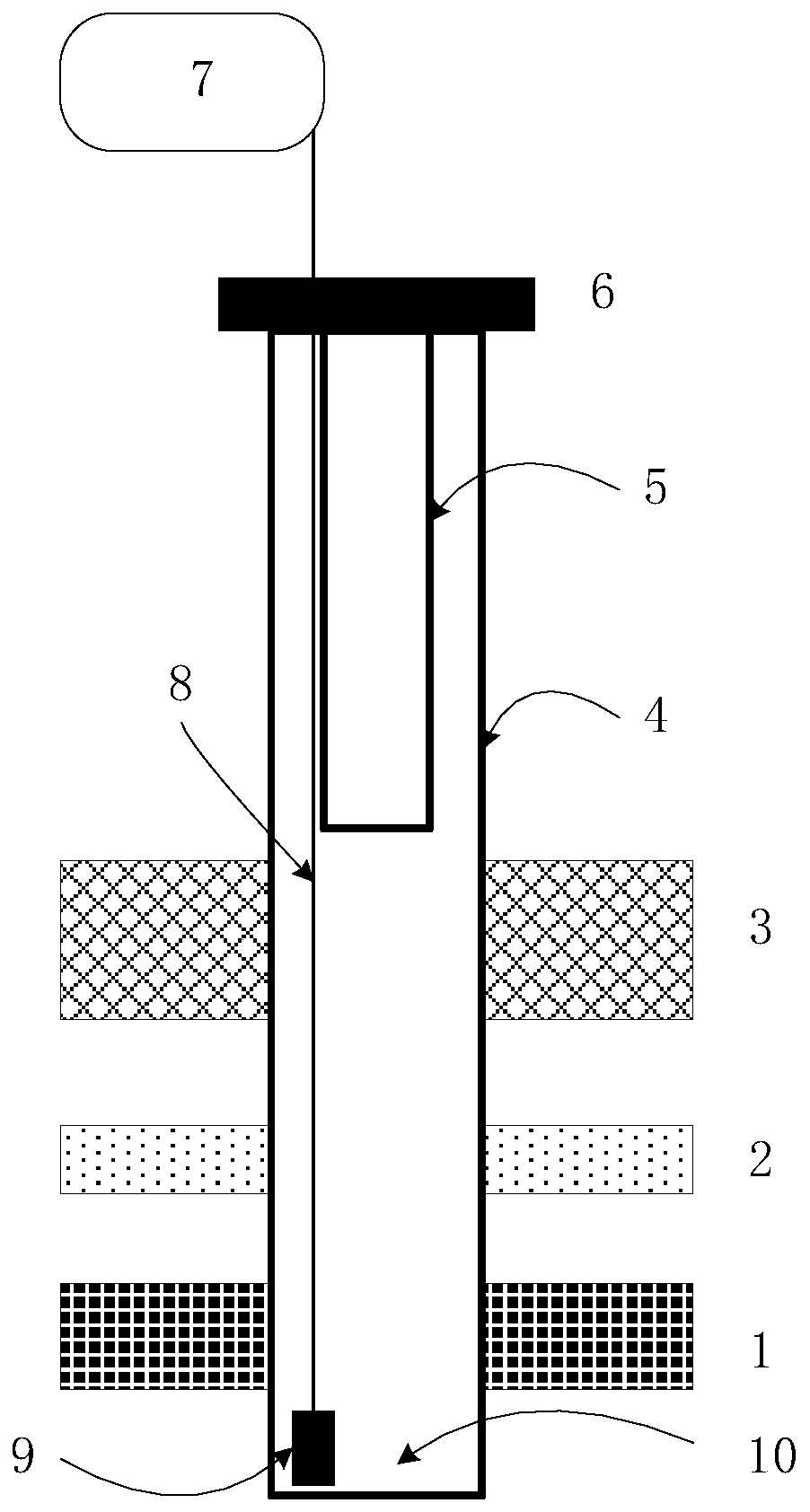

[0094] Such as figure 1 shown.

[0095] A kind of production profile monitoring method based on distributed optical fiber sound monitoring and distributed optical fiber temperature monitoring as described in embodiment 1, use DAS / DTS production profile monitor 7, armored optical cable 8 and weight 9 when realizing above-mentioned monitoring, The DAS / DTS production profile monitor 7 described therein is placed on the ground and is directly connected to the armored optical cable 8; the armored optical cable 8 is attached to the slot on the outer wall of the oil pipe 5; the weight 9 is connected to the lower end of the armored optical cable 8;

[0096] Described DAS / DTS production profile monitor 7 is made up of laser light source, sound signal receiver, temperature signal receiver and computer control and display system; The multi-mode temperature-sensing fiber sends pulsed laser light; the sound signal receiver receives the sound signal reflected from the single-mode sound-se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com