Soil straw mixing agitator, spiral conveying unit and mixing agitation method

A technology of transmission unit and mixer, which is applied in the field of agricultural machinery and fertilizer returning to the field, which can solve the problems of affecting the quality of sowing operations and excessive straw, so as to improve the efficiency of returning to the field and ensure the emergence rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0036] This embodiment is the embodiment of the soil straw mixing mixer.

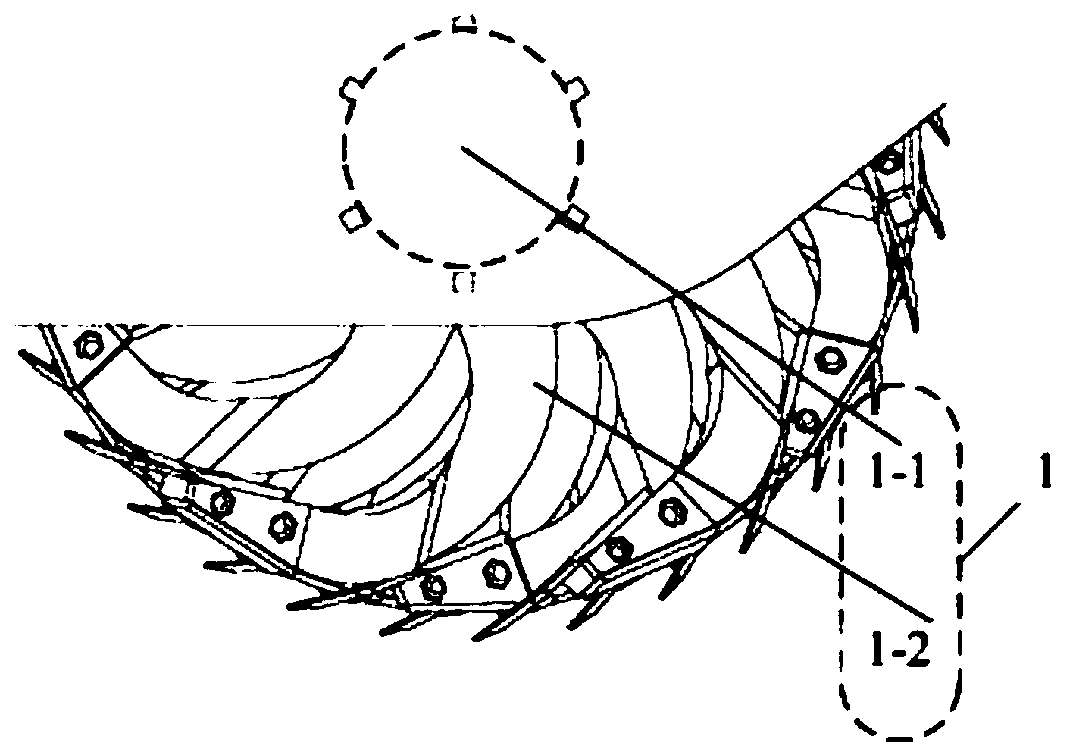

[0037] The soil straw mixing mixer under the present embodiment, the drawing is as follows figure 1 As shown; the soil straw mixing mixer is provided with a deep rotary mixing broken soil unit 1 and a spiral transmission unit 2 sequentially from front to back along the forward direction of the soil straw mixing mixer;

[0038] The deep rotary mixing unit 1 includes a first rotating shaft 1-1 and a deep rotary blade 1-2 evenly distributed on the first rotating shaft 1-1, such as figure 2 shown;

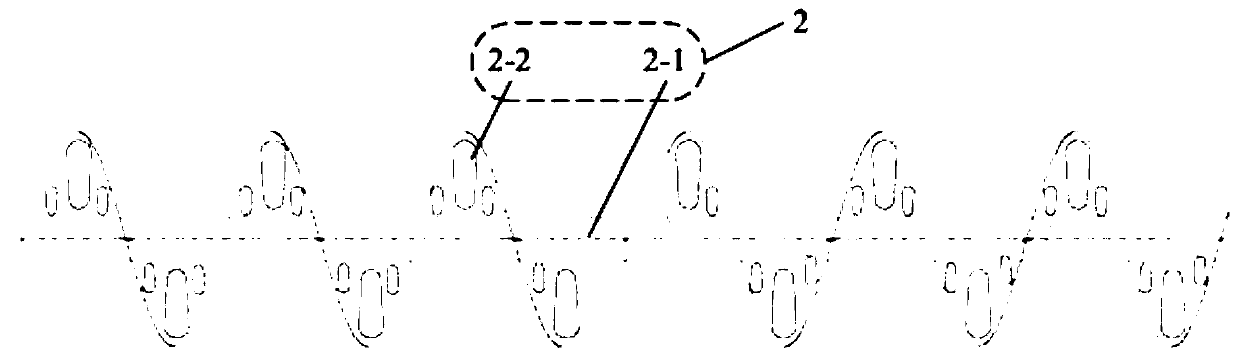

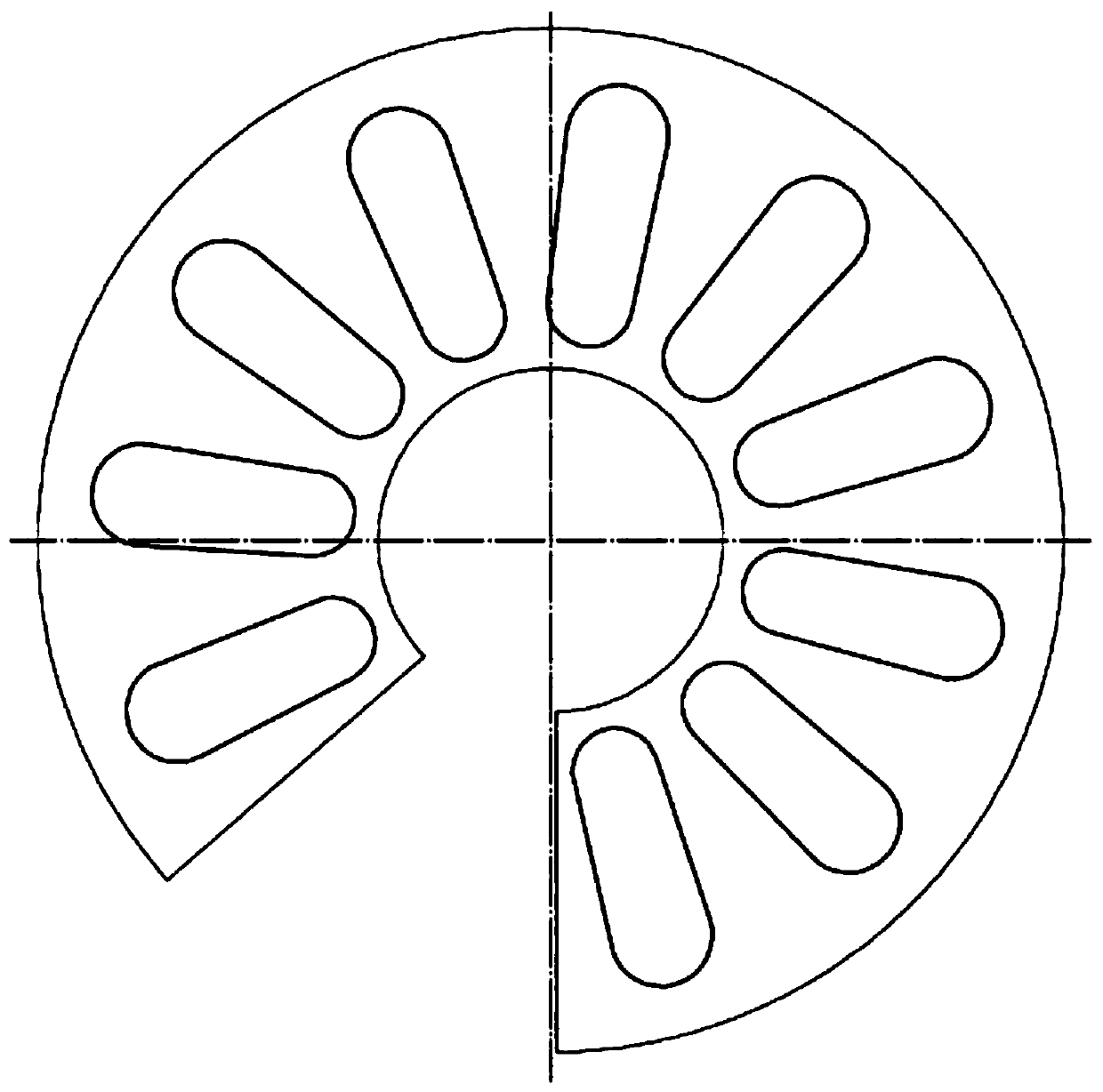

[0039] The screw transmission unit 2 includes a second rotating shaft 2-1 and two spiral blades 2-2 symmetrically distributed on the second rotating shaft 2-1, such as image 3 As shown; the helical directions of the two helical blades 2-2 are opposite, and long holes are evenly distributed on the helical blades 2-2, and the schematic diagram after the helical blades 2-2 is expanded is as follows Figure 4 A...

specific Embodiment approach 2

[0045] This embodiment is the embodiment of the screw transmission unit in the soil straw mixing mixer.

[0046] A spiral transmission unit capable of realizing secondary mixing of straw and soil, comprising a second rotating shaft 2-1 and two spiral blades 2-2 symmetrically distributed on the second rotating shaft 2-1, two spiral blades 2-2 The helical direction is opposite, and the helical blade 2-2 is evenly distributed with long holes.

specific Embodiment approach 3

[0048] This embodiment is an embodiment of the soil straw mixing and stirring method.

[0049] A method for mixing and stirring soil straw, comprising the following steps:

[0050] Step a, opening a trench for mixing soil and straw;

[0051]Step b, placing the soil straw mixing mixer on the groove, so that the groove is located in the middle of the soil straw mixing mixer;

[0052] Step c, moving the soil straw mixing mixer along the direction of the groove, specifically, moving from the screw conveying unit 2 to the direction of the deep rotary mixing crushed soil unit 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com