A battery tab transfer structure and transfer method

A technology of battery tabs and tabs, which is applied to structural parts, battery pack parts, circuits, etc., can solve problems such as not being able to meet needs, and achieve the effect of realizing automatic production lines, good transfer quality, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

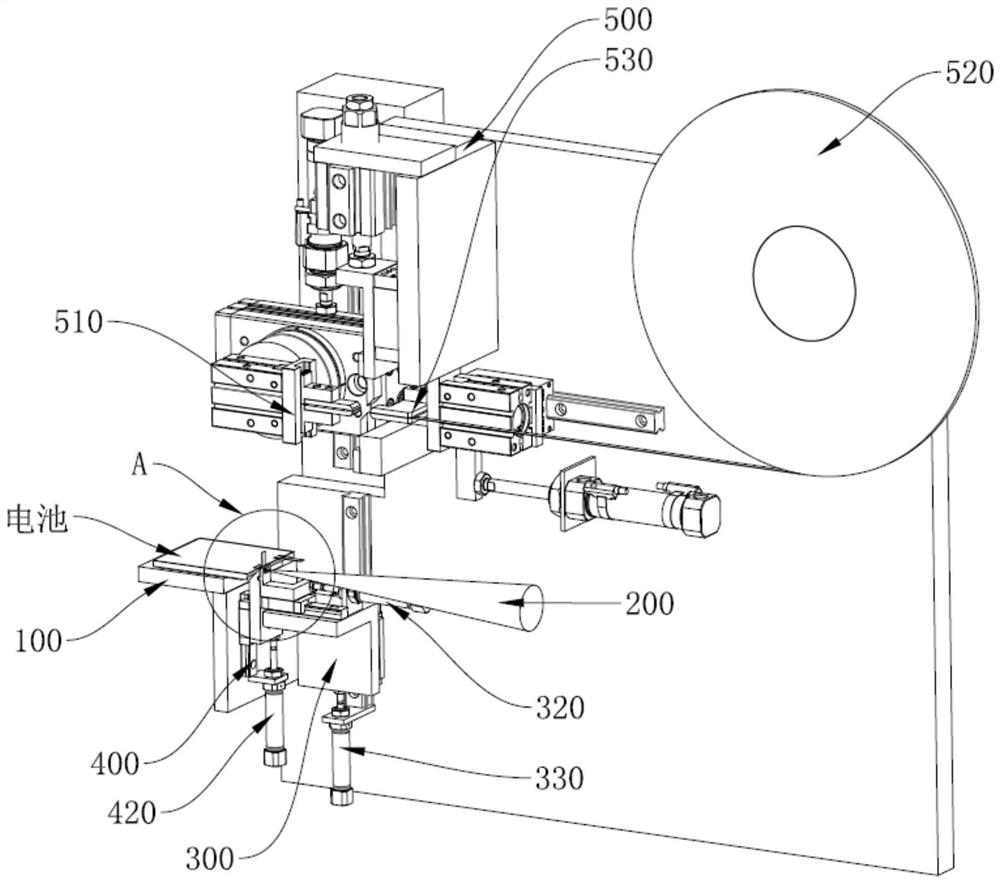

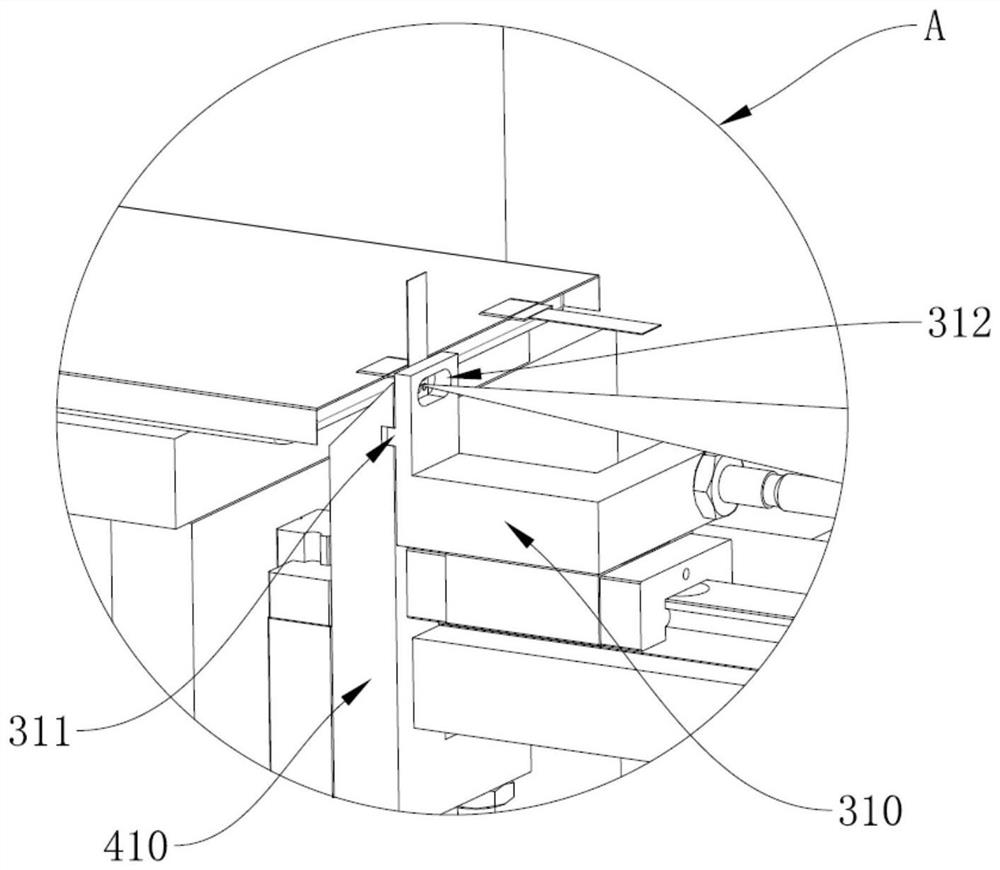

[0042] Such as Figure 1 - Figure 3 As shown in the present invention, the present invention provides a battery pole pinch structure for pushing the aluminum pole of the battery into a solderable nickel belt, including battery clamp 100 and a nickel welding mechanism, wherein the nickel welding is used. The mechanism includes the laser welding device 200, the block assembly 300, and the top block assembly 400, and the battery clamp 100 is used to position the battery pole earlings, the top block assembly 400 is used to top support aluminum Ear ear, the block assembly 300 is configured to take a vertical state when the aluminum pole is smooth, 90 °, vertically opposed to the aluminum pole and nickel belt are passed closely to the block assembly 300 and the top block assembly 400. Fixed, the laser welding device 200 is used to weld the nickel tape and an aluminum pole.

[0043]When the battery pole is transferred, the aluminum pole ear is supported by the top block assembly 400, and ...

Embodiment 2

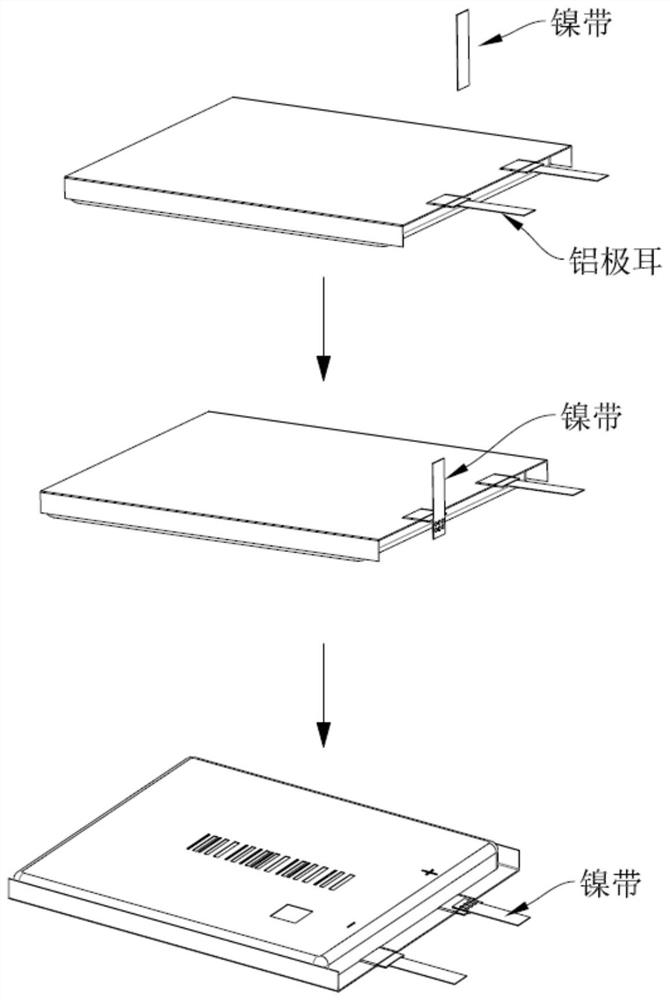

[0062] Combine Figure 4 As shown, the second embodiment of the present invention provides a transfer method of the battery pole pinch structure described in the first embodiment, including the following steps:

[0063] Step S0: Start the block assembly 300 so that the block assembly 300 rises to a position higher than the extract of the battery to be placed;

[0064] Step S1: The battery clamp 100 moves the fabricated battery from the previous step to level fixed, at which point the aluminum polar ear is toward the nickel welding mechanism;

[0065] Step S2: Starting the top block assembly 400 causes the top block body 410 to abut against the lower end surface of the aluminum pool;

[0066] Step S3: Start the block assembly 300 and move the aluminum pole scrape 90 ° vertically by moving down the aluminum pole.

[0067] Step S4: Place the nickel tape vertically in the position of the vertical aluminum pole ear.

[0068] Step S5: The startup block assembly 300 is moved to the top b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com