Crankshaft transfer trolley capable of automatically moving up and down

A technology for automatic lifting and transfer vehicles, applied to motor vehicles, multi-axis trolleys, trolleys, etc., can solve the problems of reducing efficiency and increasing labor intensity of the crankshaft, and achieve the effects of reducing labor intensity, smooth movement, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

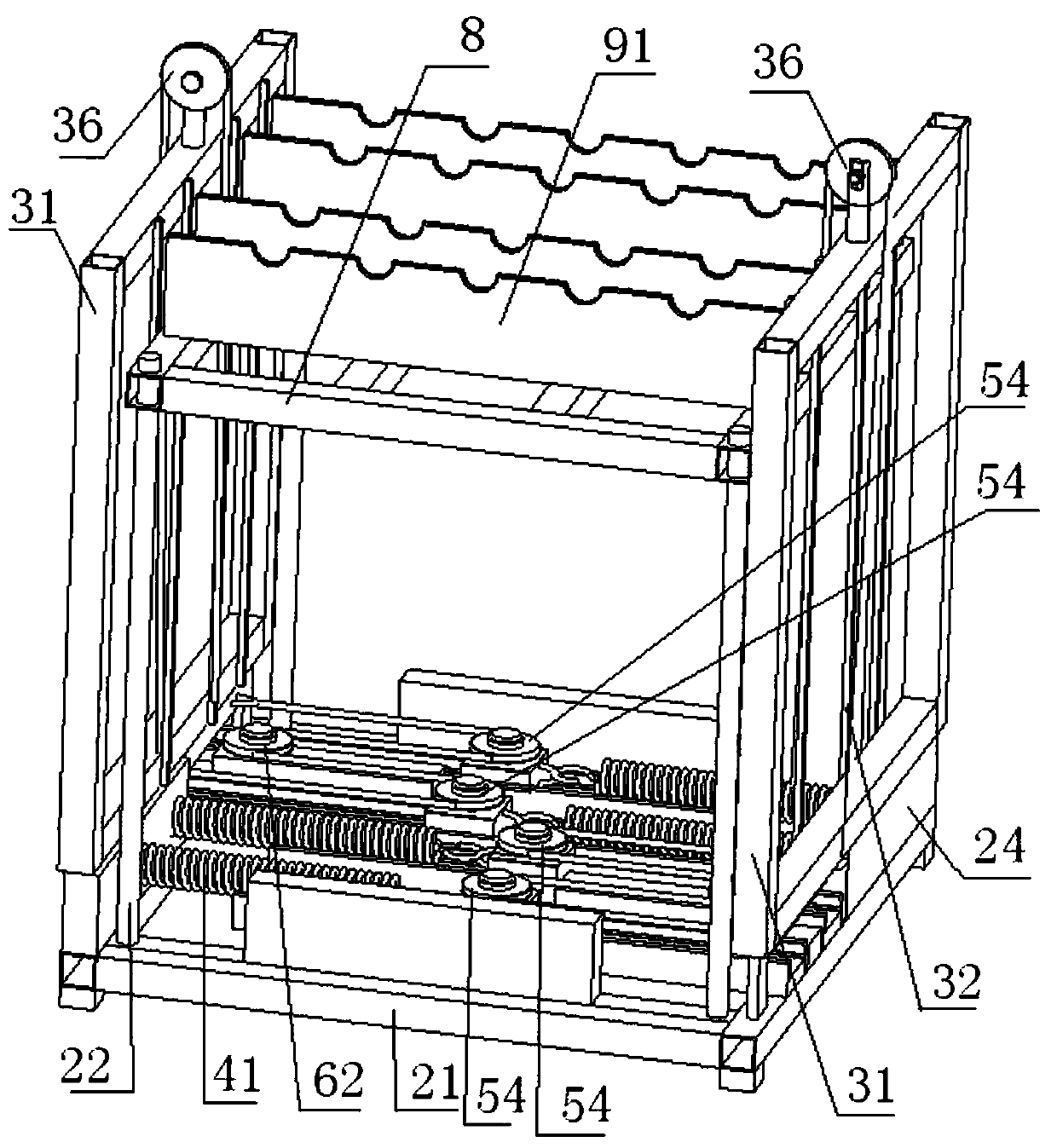

[0055] see figure 1 , an automatic lifting crankshaft transfer vehicle, comprising a frame 1, a driving device installed on the frame, a lifting frame 8 and a crankshaft support plate 9;

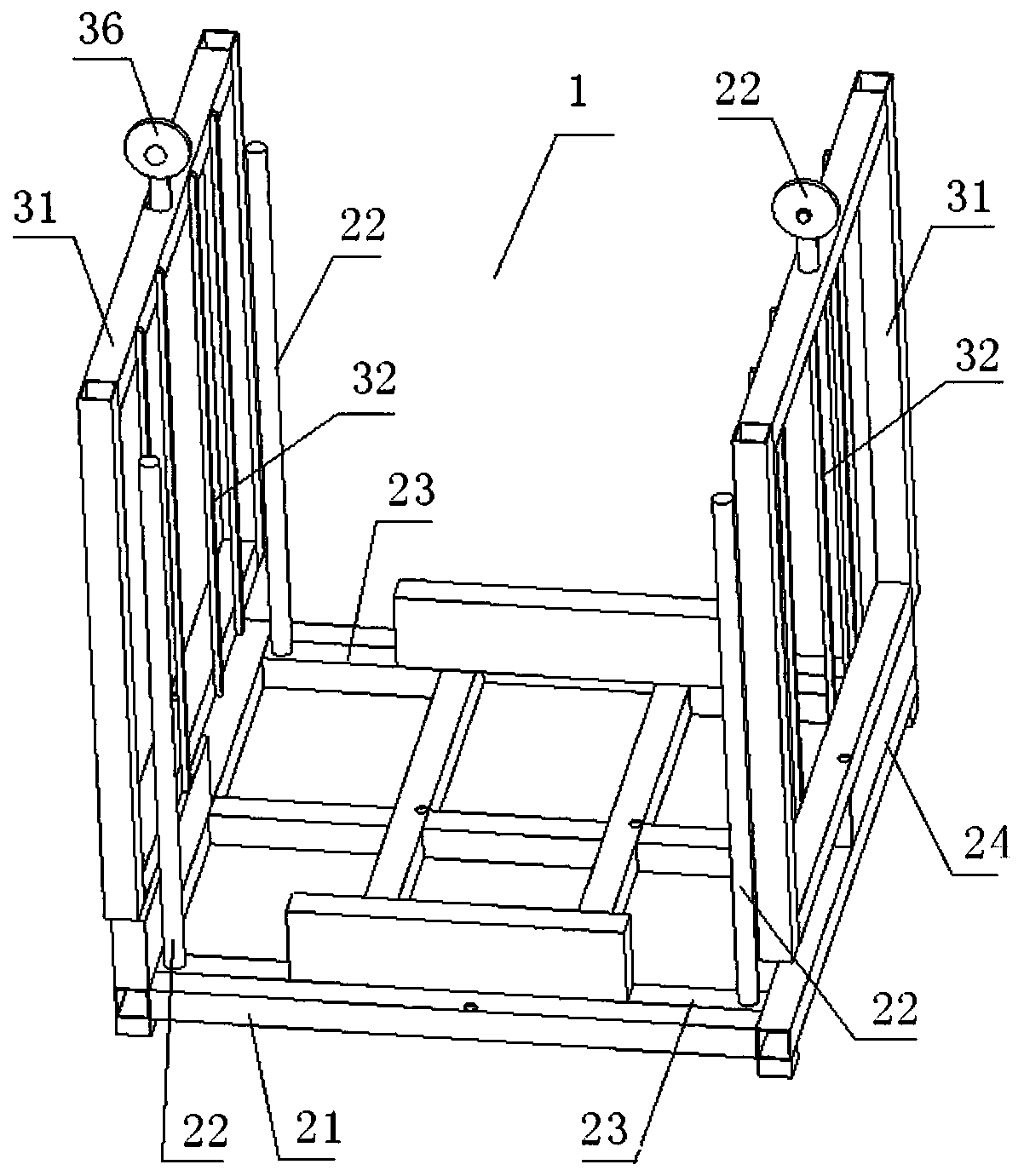

[0056] see figure 2 , the rack 1 includes a rack body 2 and a baffle 3;

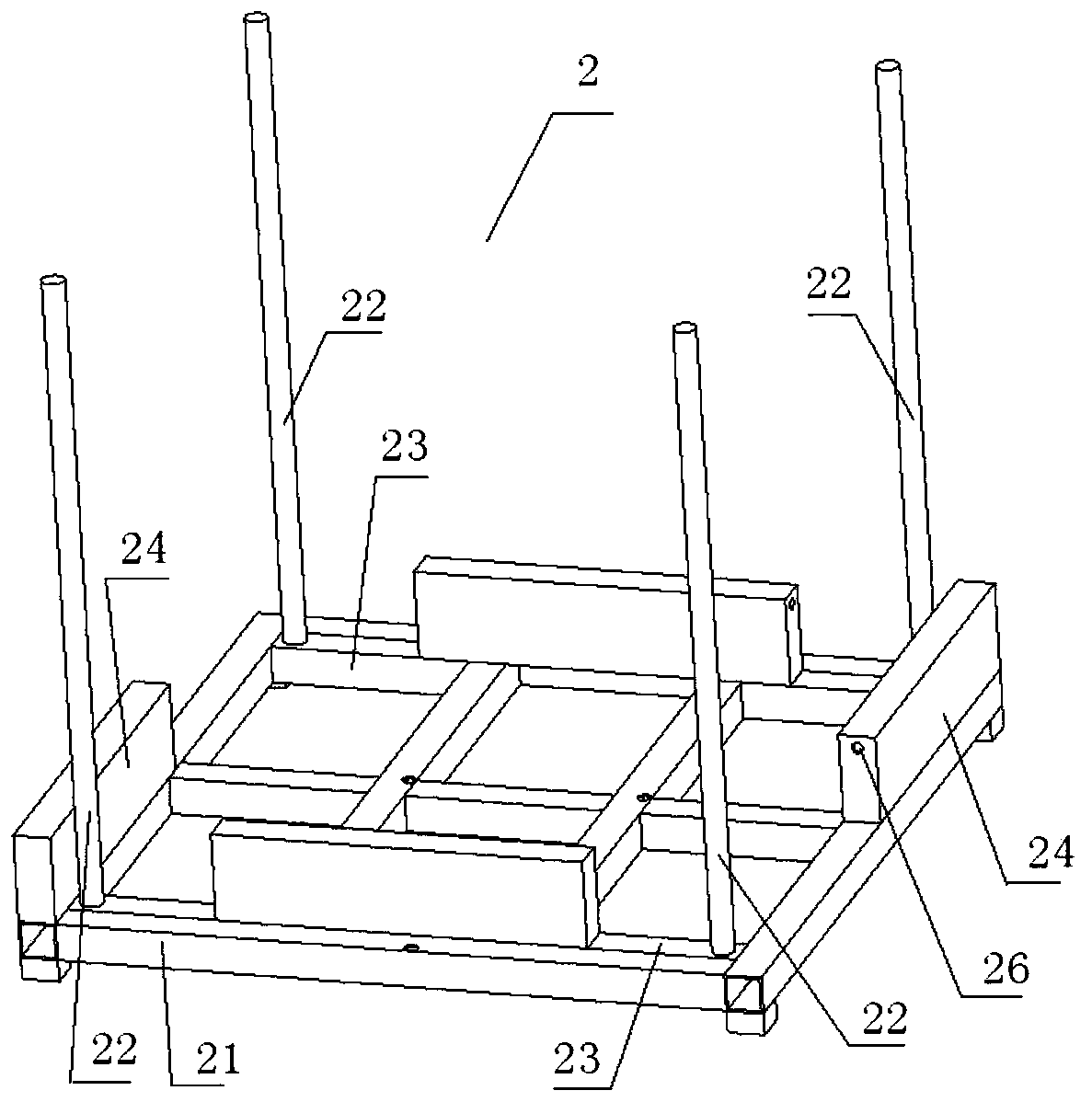

[0057] see image 3 , Figure 4 , the frame body 2 includes a base 21, a guide column 22 installed on the base 21, and the edge of the base 21 has a side support plate 24;

[0058] see Image 6 , the baffle 3 includes a baffle frame 31 and a guide bar 32 installed on the baffle frame 31, the first pulley assembly 34 is installed on the baffle frame 31, and the first pulley assembly 34 includes a first pulley 36;

[0059] see figure 1 , the lifting frame 8 is slidably matched with the guide column 22, the baffle frame 31 is fixed on the bottom plate 21, the cra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com