Repeatable locking and separating device

A separation device, repeated locking technology, applied in the direction of the docking device of the aerospace vehicle, can solve the problems of inability to meet on-orbit maintenance and service, non-reusable structure, damage to electronic components, etc., to achieve high reliability, vibration and shock Small, easy-to-maintain effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

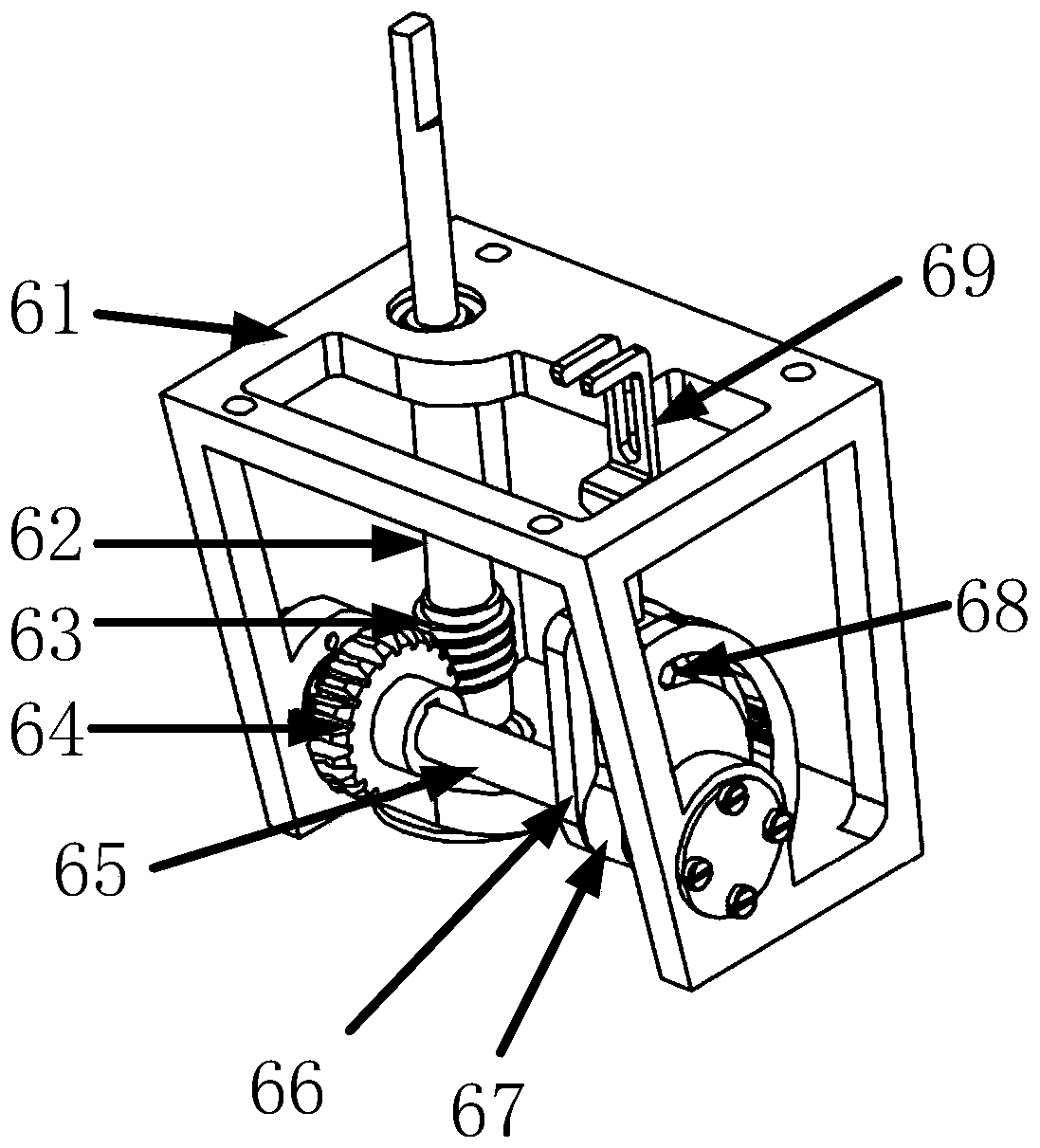

[0032] A re-lockable separation device comprising:

[0033] Bracket 61, vertical shaft 62, worm 63, turbine 64, horizontal shaft 65, cam 66, chute 67, pin shaft 68, locking hook 69, first bearing, second bearing, third bearing;

[0034] The vertical shaft 62 is fixedly connected with the worm 63, the vertical shaft 62 is mounted on the bracket 61 through the first bearing; the worm wheel 64 is fixedly connected with the horizontal shaft 65, and the horizontal shaft 65 is mounted on the bracket 61 through the second bearing On; the worm 63 cooperates with the turbine 64 for transmission;

[0035] Described chute 67 is installed on the cross shaft 65 by the 3rd bearing, a cam 66 is respectively installed on the both sides of described chute 67, and two cams 66 are fixedly connected with cross shaft 65, and two cams 66 are all provided with guide groove; the chute 67 is provided with a cavity and a waist groove, and the locking hook 69 is inserted into the cavity; the pin shaft ...

Embodiment 2

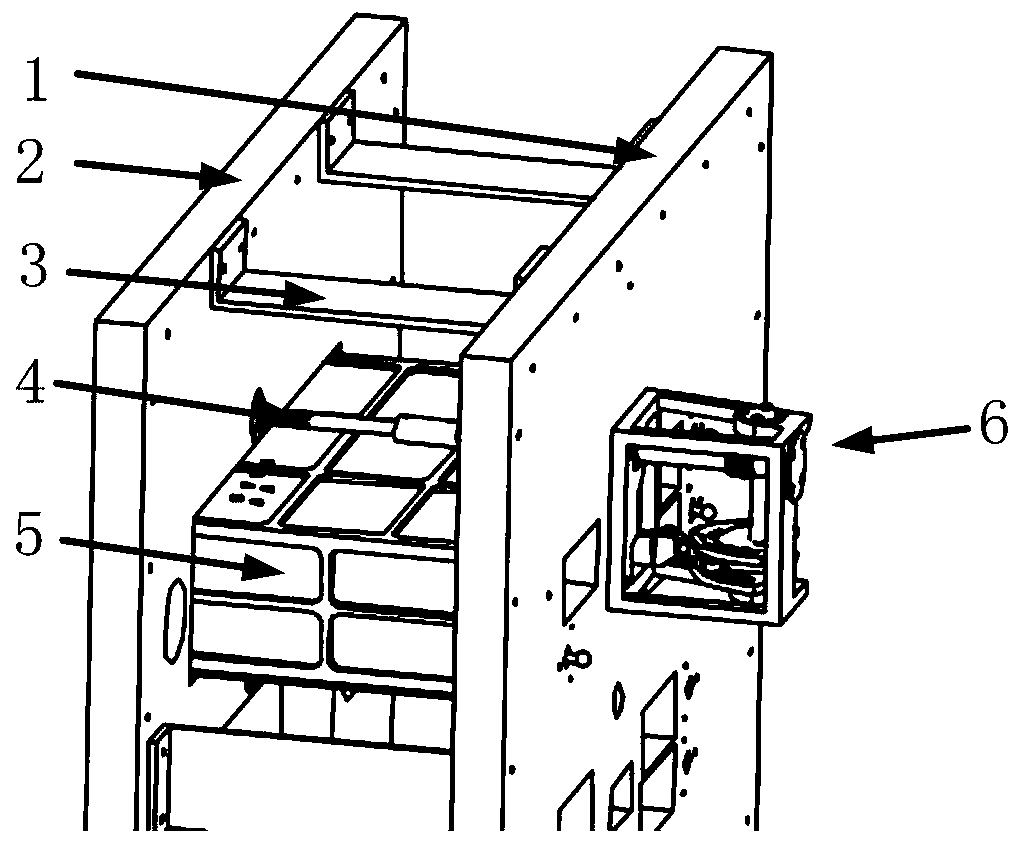

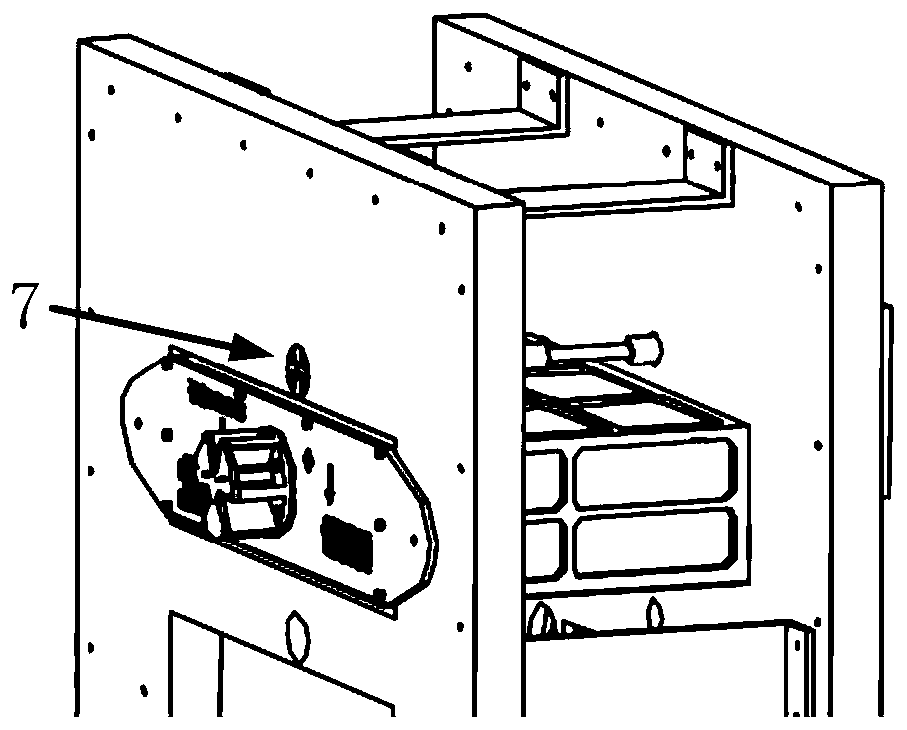

[0043] This embodiment is applied to on-orbit spacecraft or satellites, and relevant components need to be locked and separated. Such as figure 1 , 2 Shown is a schematic diagram of this embodiment applied to an on-orbit spacecraft or satellite locking and separation environment. The local structure of an on-orbit spacecraft is composed of an inner side plate 1 and an outer side plate 2, and the inner and outer side plates are supported by a bracket plate 3 , the on-orbit replacement module 5 can be inserted and removed on the rail through a mechanical arm or other mechanism, and when the on-orbit replacement module 5 is inserted into the designated position of the spacecraft, the unlocking end 7 is locked by the mechanical arm or other mechanism. When the on-rail replacement module 5 needs to be replaced, the unlocking end 7 is also operated by a mechanical arm or other mechanism to unlock, and then the on-rail replacement module 5 is pulled out.

[0044] The device of this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com