Connecting structure of aluminum square tube unit

A connection structure and screw connection technology, which is applied in building construction, covering/lining, construction, etc., can solve problems such as deformation, poor fireproof effect, easy cracking, etc., and achieve high efficacy, prolong service life, and high bite.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

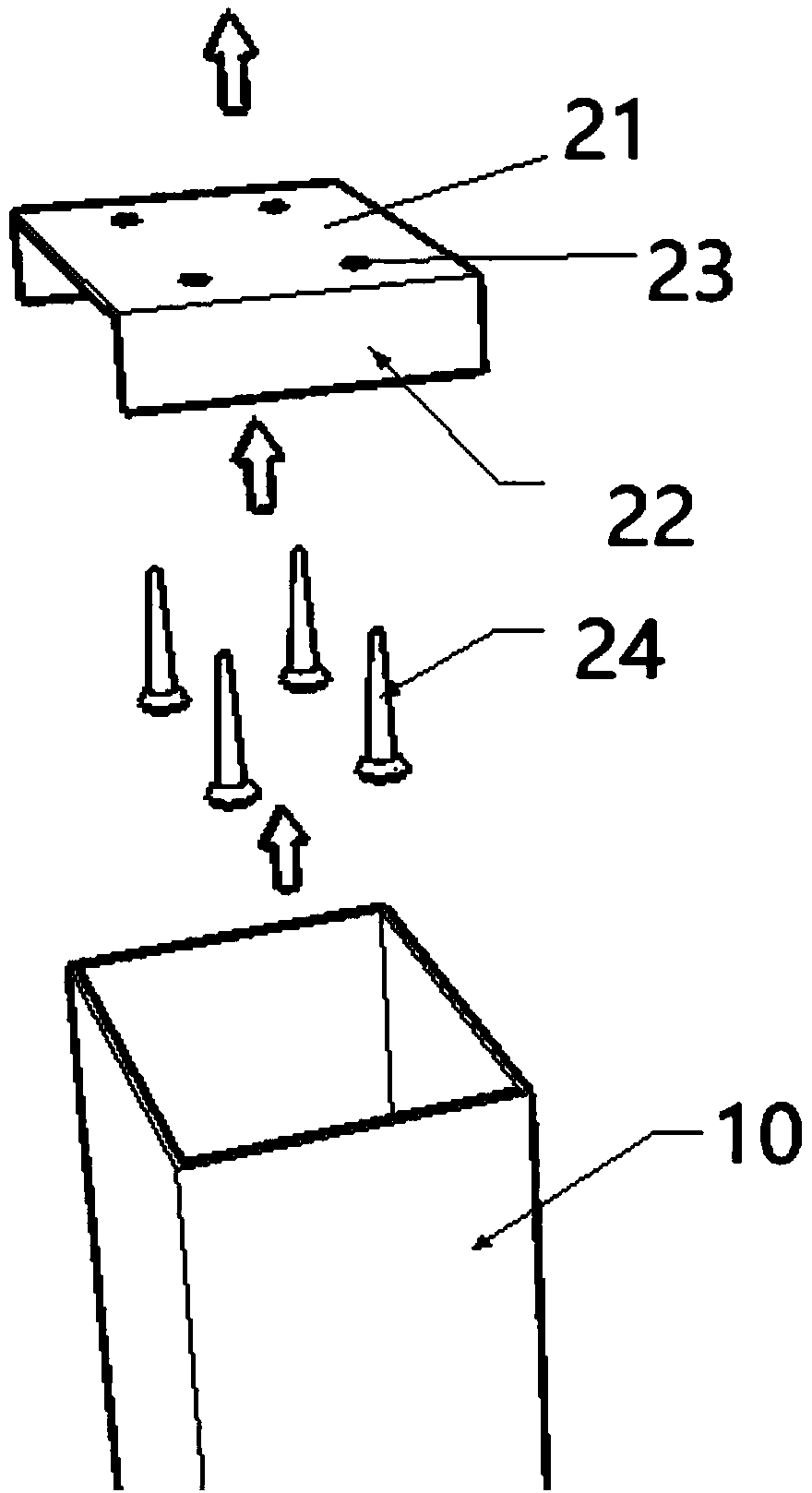

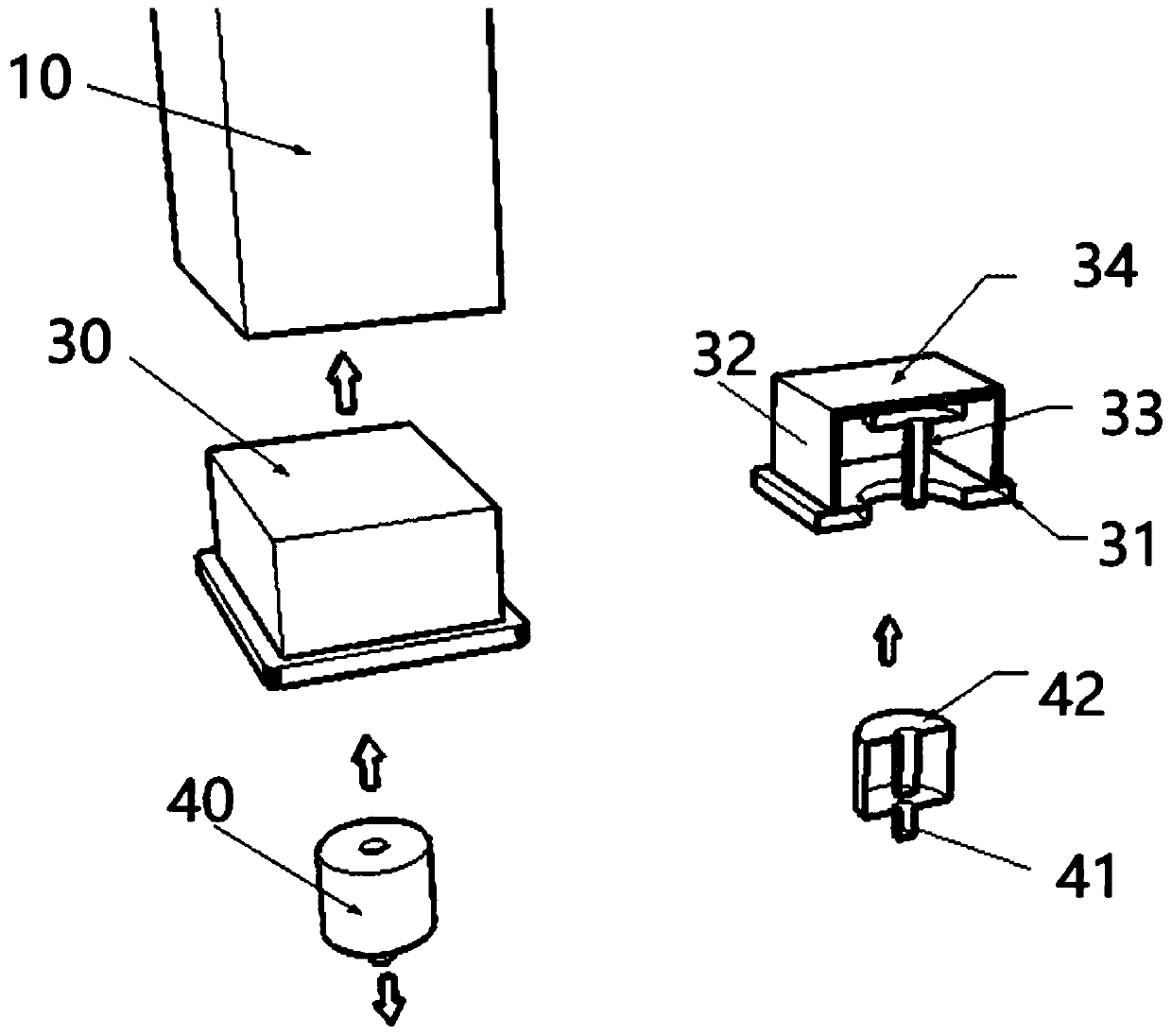

[0025] see figure 1 and figure 2 , as shown in the legend, a connection structure of an aluminum square pass unit, including an aluminum imitation wood grain square pass 10, a top installation base layer (not shown in the figure) and a bottom installation base layer (not shown in the figure), It also includes a first positioning member 20 and a second positioning member 30. The first positioning member 20 is fixed on the top mounting base, the second positioning member 30 is fixed on the bottom mounting base, and the first positioning member 20 is inserted into the aluminum imitation wood grain square. In the upper port of the pass 10, the second positioning member 30 is inserted into the lower port of the aluminum imitation wood grain square pass 10, and at least one of the first positioning member 20 and the second positioning member 30 restricts the aluminum imitation wood grain square pass. 10 Move in the horizontal direction.

[0026] In a preferred implementation in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com