Quenching Furnaces for Vane Pump Rotors

A vane pump and quenching furnace technology, applied in the field of quenching furnace, can solve the problems of unreasonable, different preheating, incomplete austenitization, etc., and achieve the effect of making full use of energy and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

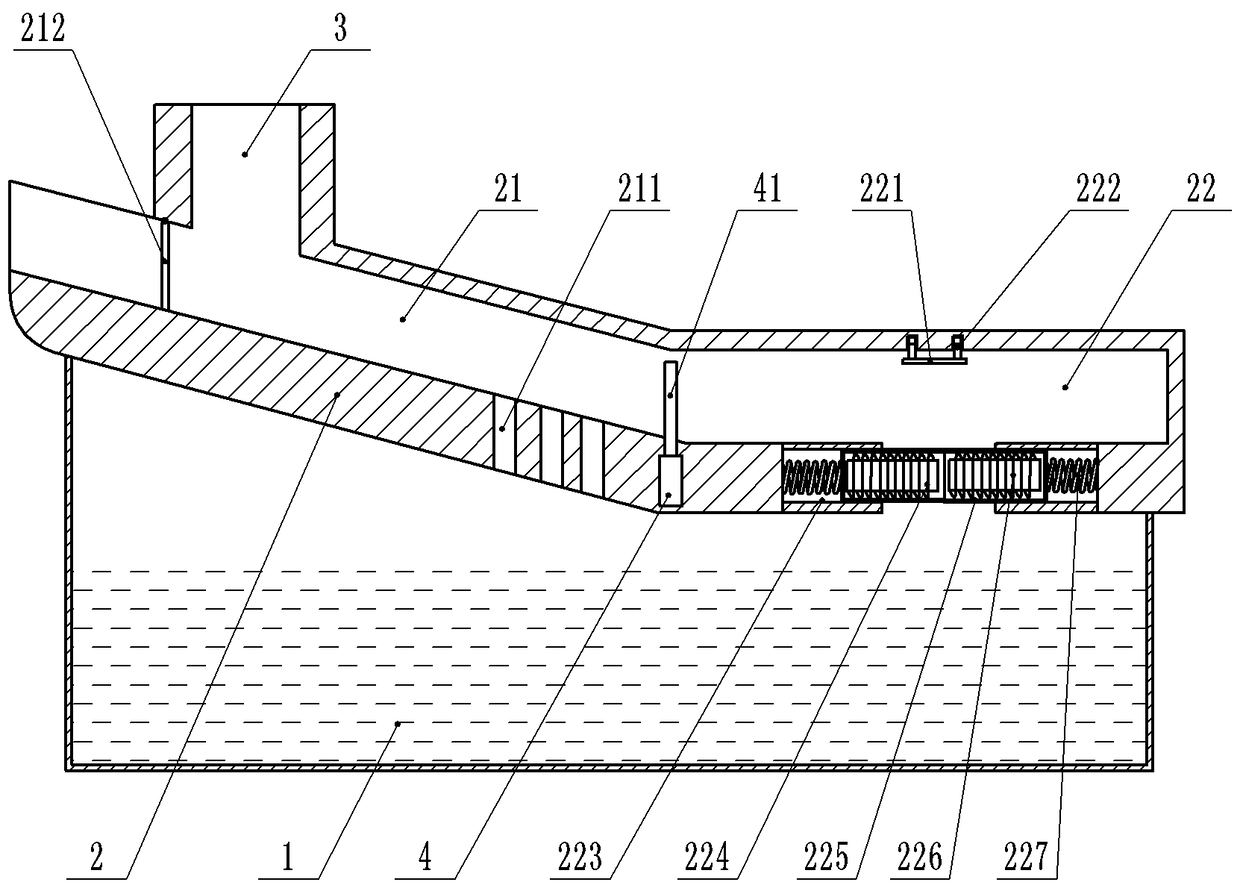

[0019] The reference signs in the drawings of the description include: oil pool 1, furnace body 2, preheating chute section 21, through hole 211, feed door 212, heating flat section 22, moving plate 221, telescopic rod 222, chute 223 , the first coil 224 , the slider 225 , the second coil 226 , the spring 227 , the exhaust port 3 , the cam 4 , and the separator 41 .

[0020] Such as figure 1 As shown, the quenching furnace for the vane pump rotor includes a furnace body 2, a quenching unit and a smoke exhaust unit. The furnace body 2 includes a preheating chute section 21 and a heating flat section 22 connected together, and the preheating chute section 21 A partition 41 is movably connected to the junction with the heating flat section 22 . The bottom of body of furnace 2 is provided with motor and the cam 4 that is used to drive partition 41 to move up and down, the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com