Test apparatus for material cutting performance testing and test method

A technology for cutting performance and testing instruments, applied in the field of oral teaching models, can solve problems such as unnatural biological hard tissue grinding scenarios, simulating material cutting feeling of alveolar bone approaching, and simulating material development difficulties, etc., and achieve sample preparation. Low requirements, real cutting data, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to understand the technical content of the present invention more clearly, the following examples are given in detail, the purpose of which is only to better understand the content of the present invention but not to limit the protection scope of the present invention.

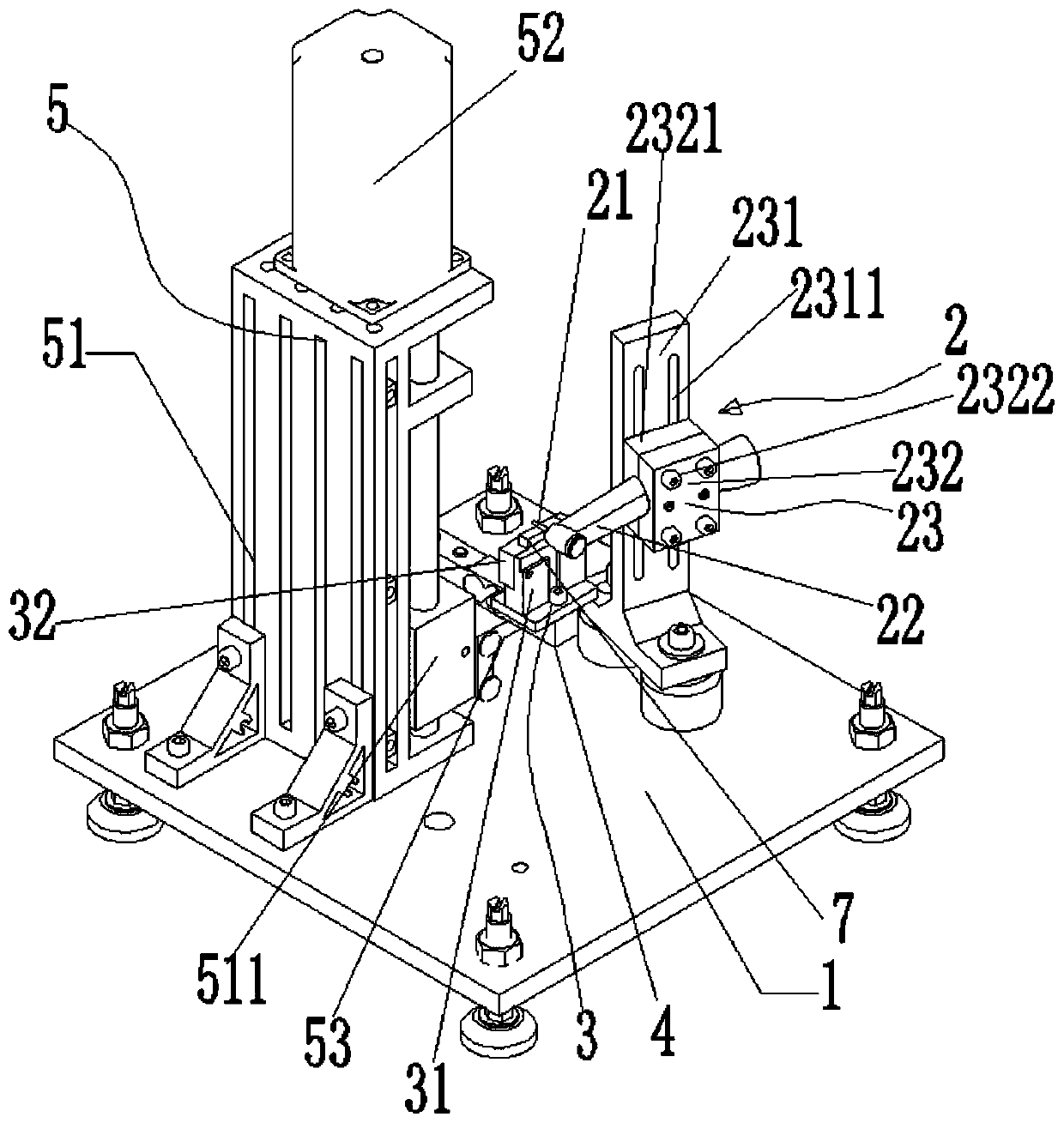

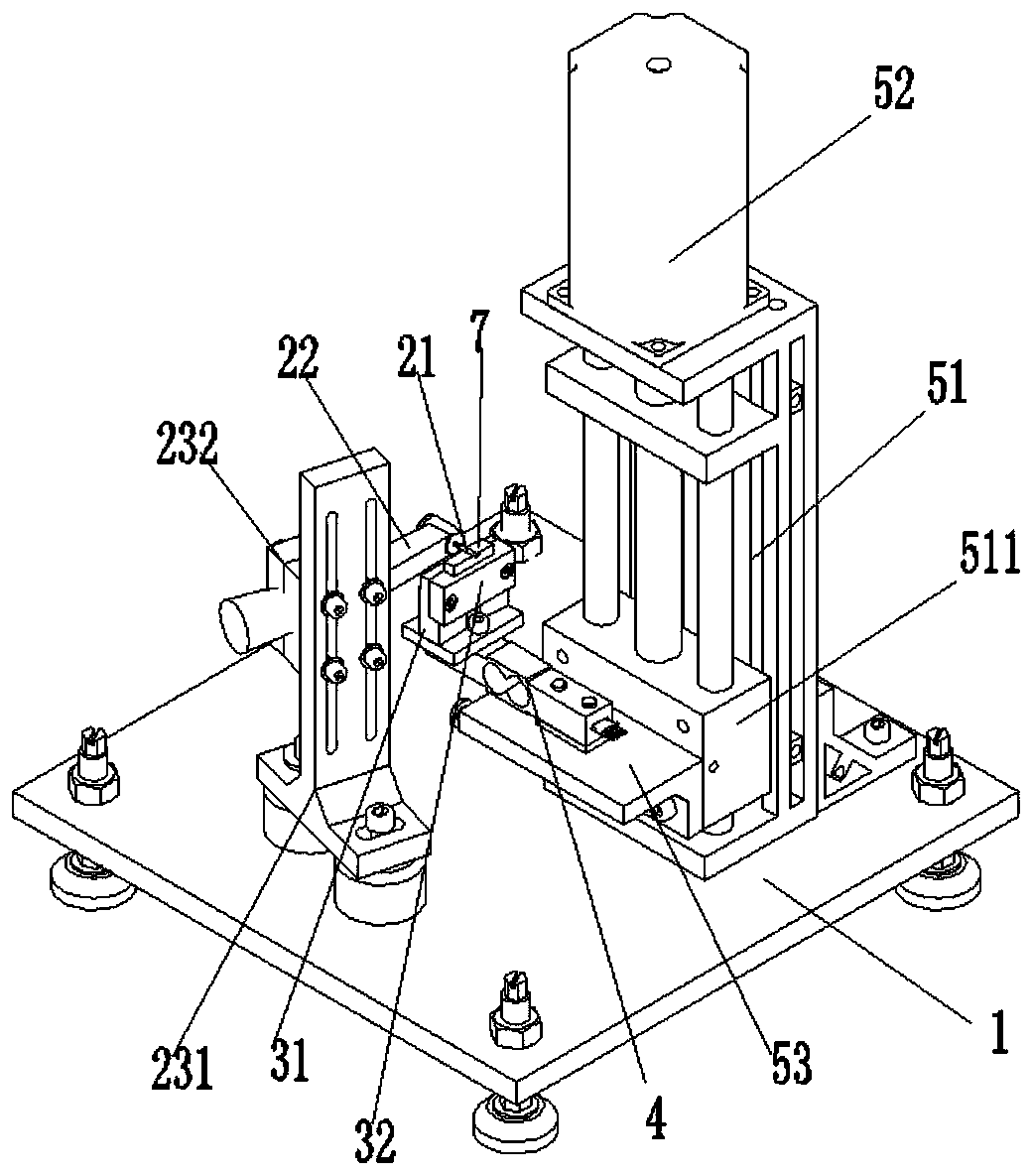

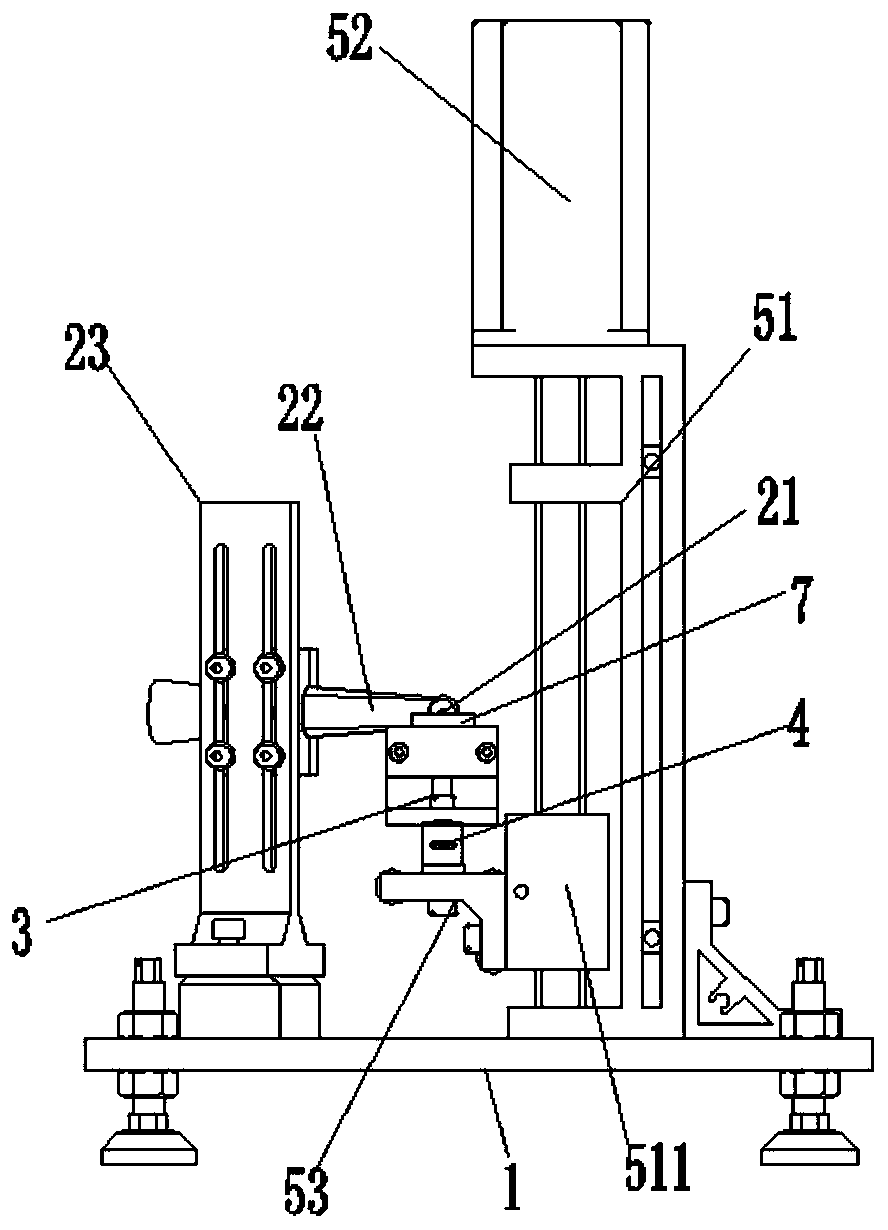

[0034] figure 1 It is a perspective view of a testing instrument used for material cutting performance testing according to the present invention; figure 2 It is a perspective view of another perspective of the test instrument used for material cutting performance testing in the present invention; image 3 It is a side view of the test instrument used in the material cutting performance test of the present invention; Figure 4 It is the top view of the test instrument used for material cutting performance test of the present invention; as figure 1 , figure 2 , image 3 and Figure 4As shown, a test instrument for testing the cutting performance of materials includes a workbench 1, a cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com