Crystal micro-texture orientation obtaining device and obtaining method

An acquisition device and acquisition method technology, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of limited spatial resolution and inability to apply large plastic deformation samples, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0133] Determination of Micro Texture Orientation of AZ31B Magnesium Alloy Rolled Sheets:

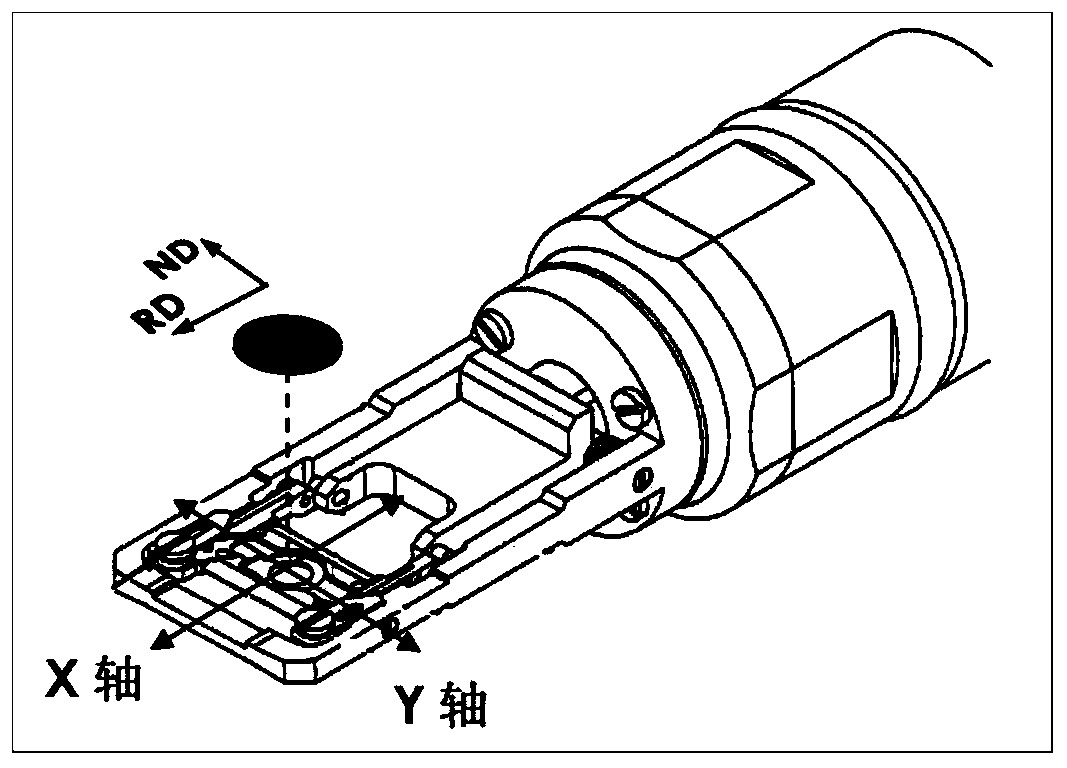

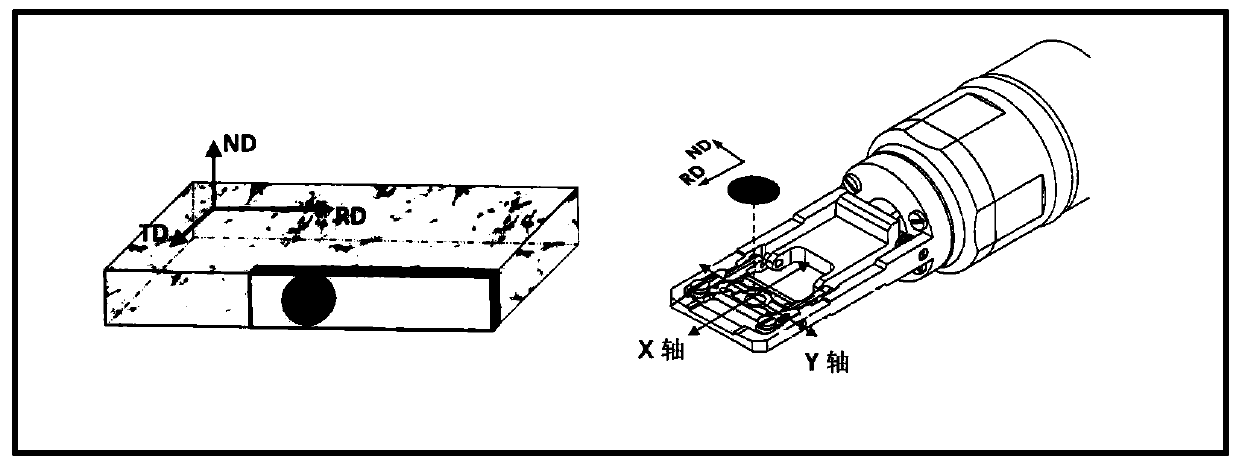

[0134] (1) Cut the sample into 0.5mm thin slices along the rolling direction (RD) and normal direction (ND) of the magnesium alloy rolling plate, such as image 3 shown. Use 200#, 400#, 600# and 800# metallographic sandpaper to grind the thin slice sample to 0.1mm in turn, cut the thin slice sample into a Φ3mm disc with a TEM sample punch, and mark the rolling direction RD of the rolled plate on the disc And the ND direction of the normal line of the rolling plate, using the HNO3-CH3OH electrolyte, the TEM observation sample was prepared by the electrolytic double spray method.

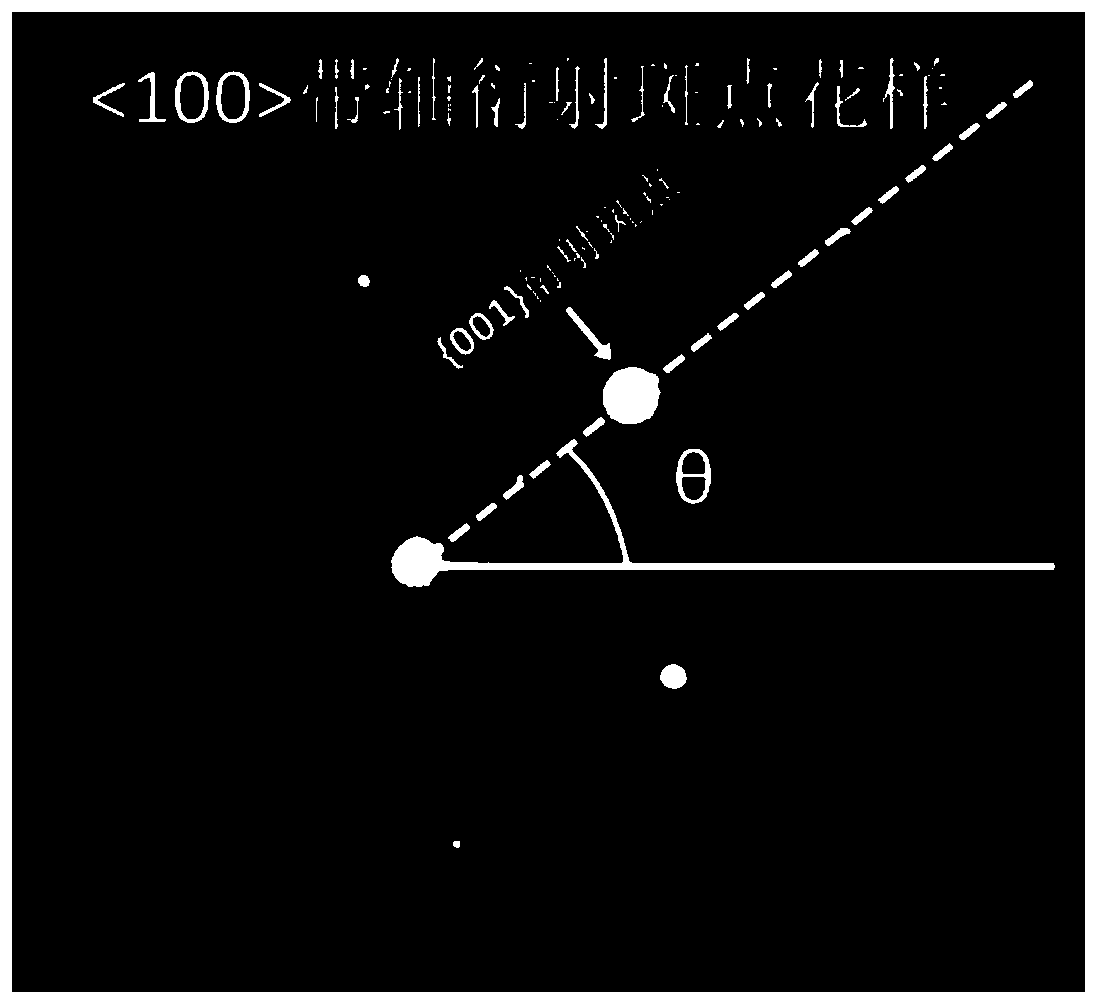

[0135] (2) Place the wafer sample on the TEM bidirectional tilting sample stage, and put it into the transmission electron microscope for observation. Note that when placing the sample, make sure that the RD direction marked on the disc sample is consistent with the X-axis direction of the shaft horizontal di...

Embodiment 2

[0151] Determination of micro-texture orientation for industrial pure aluminum extruded rods:

[0152] (1) Cut the sample along the cross-section of the extruded rod perpendicular to the extrusion direction (ED) (eg Figure 5 Shown), cut into 0.5mm thin slices, grind the thin slice samples to 0.1mm with 200#, 400#, 600# and 800# metallographic sandpaper in turn, cut the thin slice samples into Φ3mm discs with TEM sample punch, and The extrusion direction (TD1) and transverse direction (TD2) of the bar are marked on the wafer, and the HNO3-CH3OH electrolyte is used to prepare the TEM observation sample by the electrolytic double-spray method.

[0153] (2) Place the wafer sample on the TEM bidirectional tilting sample stage, and put it into the transmission electron microscope for observation. Note that when placing the sample, make sure that the TD2 direction marked in the disc sample is consistent with the X-axis direction of the shaft horizontal direction of the TEM bidirect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com