Crimping type roof lightning protection belt and installation method thereof

An installation method and lightning protection belt technology, which are used in the installation of cables, lighting conductors, corona discharge devices, etc., can solve the problems of roof lightning protection belts without both stainless steel composite material lightning protection belts, concrete can not be vibrated, and the appearance is not beautiful. To achieve the effect of simple and convenient installation and operation, firm and reliable connection, and prevention of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings of the specification.

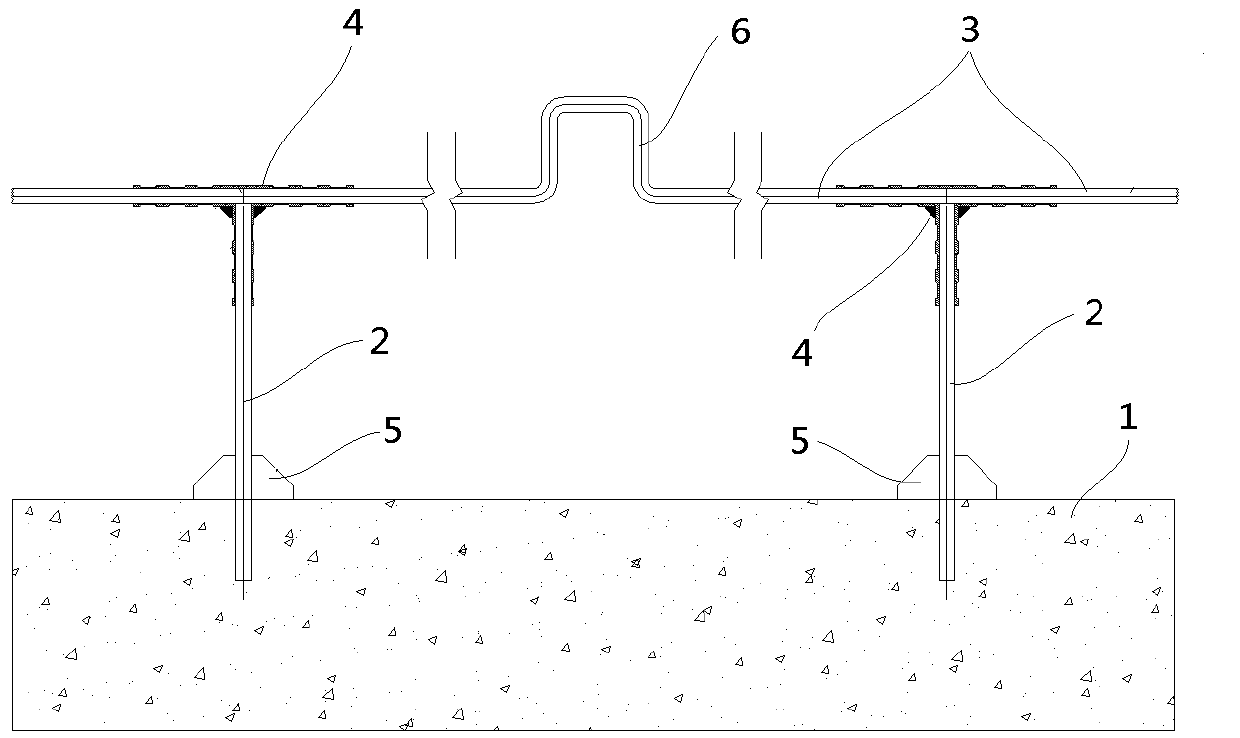

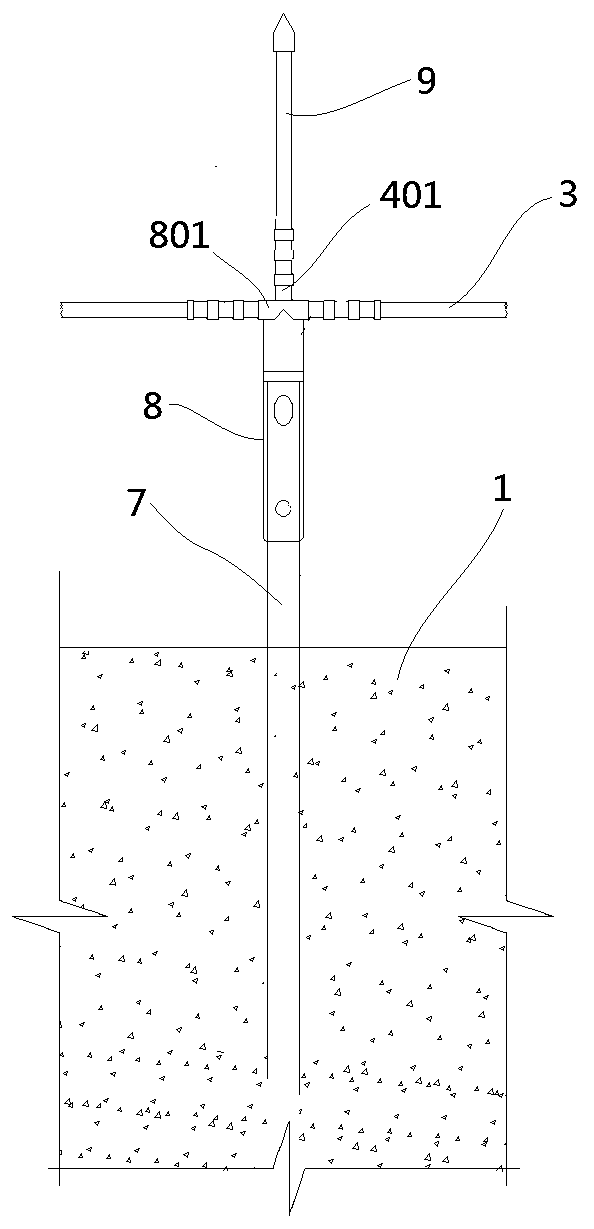

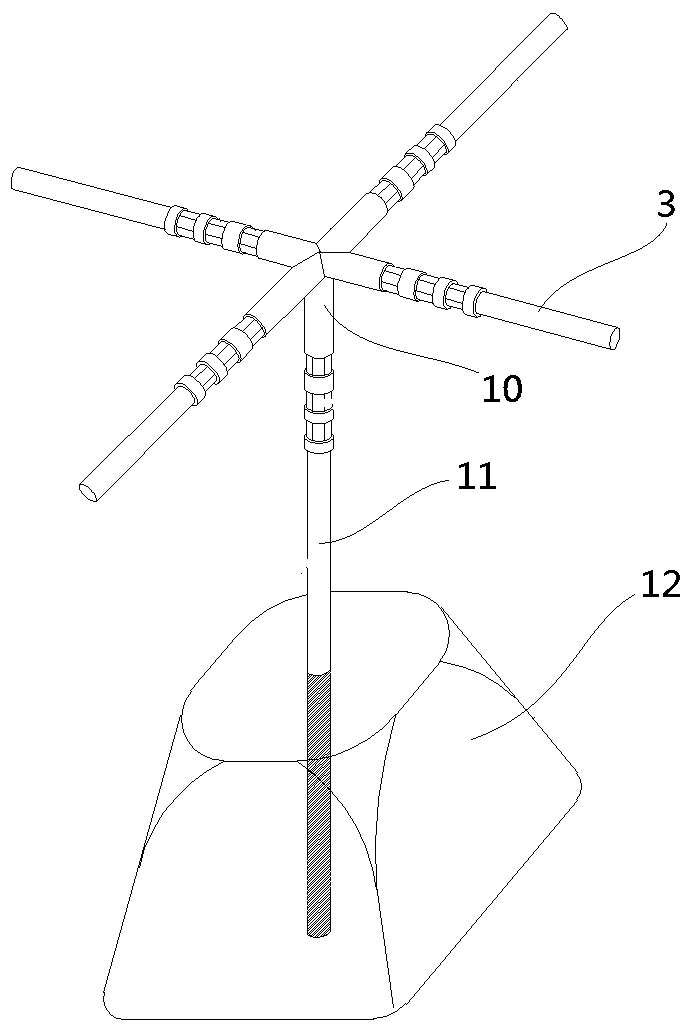

[0028] Such as Figure 1-3 As shown, a crimping type roof lightning protection belt includes parapet support rod 2, roof support rod 11, connecting rod 3, two-way crimping joint, three-way crimping joint 4, four-way crimping joint, five-way pressure Connecting connector 10, double-hole connecting plate 8 and short-pin air-termination device 9; parapet support rods 2 are distributed along the parapet wall 1 and fixed on the parapet wall 1. The parapet support rod 2 is covered with protective cap 5 and protective cap 5 The bottom is pasted and fixed on the surface of the parapet wall 1. The parapet wall support rod 2 is provided with a three-way crimping joint 4, the upper end of the parapet wall 1 lightning belt down conductor 7 is connected to the double hole connecting plate 8, and the top of the double hole connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com