Motor and support structure thereof

A support structure and cylinder technology, applied in the direction of magnetic circuit shape/pattern/structure, electrical components, electromechanical devices, etc., can solve the problem of high cost, achieve the effect of improving product performance and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

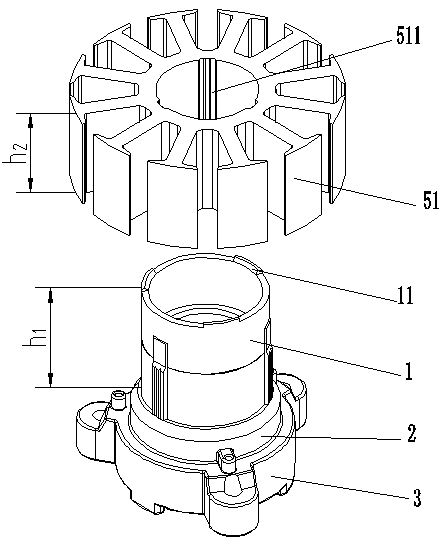

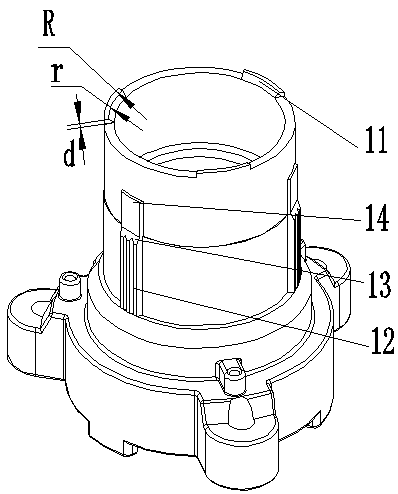

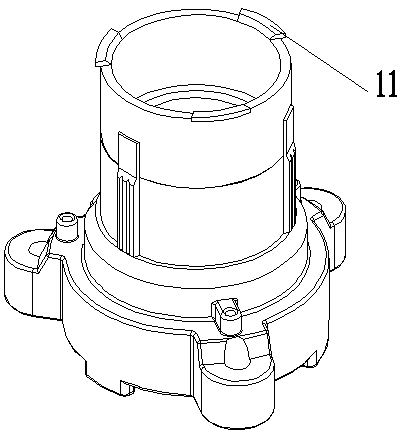

[0021] Such as Figures 1 to 3 As shown, the present invention proposes a bracket structure of a motor, including: a cylinder, the outer diameter of which is enlarged step by step from one end to the other to form a first cylinder 1, a second cylinder 2 and a third cylinder 3 , so that the first step is formed between the first cylinder 1 and the second cylinder 2, the end surface of the first cylinder 1 is provided with a crimping structure 11, the stator core 51 is set on the first cylinder 1, and the two ends respectively pass through The first step and the crimping structure 11 make the stator core fixed, which can replace the traditional support structure and the stator core circumferential surface interference fit or adhesive to realize the support and iron core fit, simplifying the operation process and the manufacturing cost of the motor At the same time, it solves the problem of loose fit between the bracket structure and the stator core, improves product performance,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com