Cutting and stringing integrated novel stringing machine and work method thereof

A skewering machine, a new type of technology, applied in the field of food skewering machine, can solve the problems of low production efficiency and unable to meet the production capacity demand, and achieve the effect of simple structure, ingenious design and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

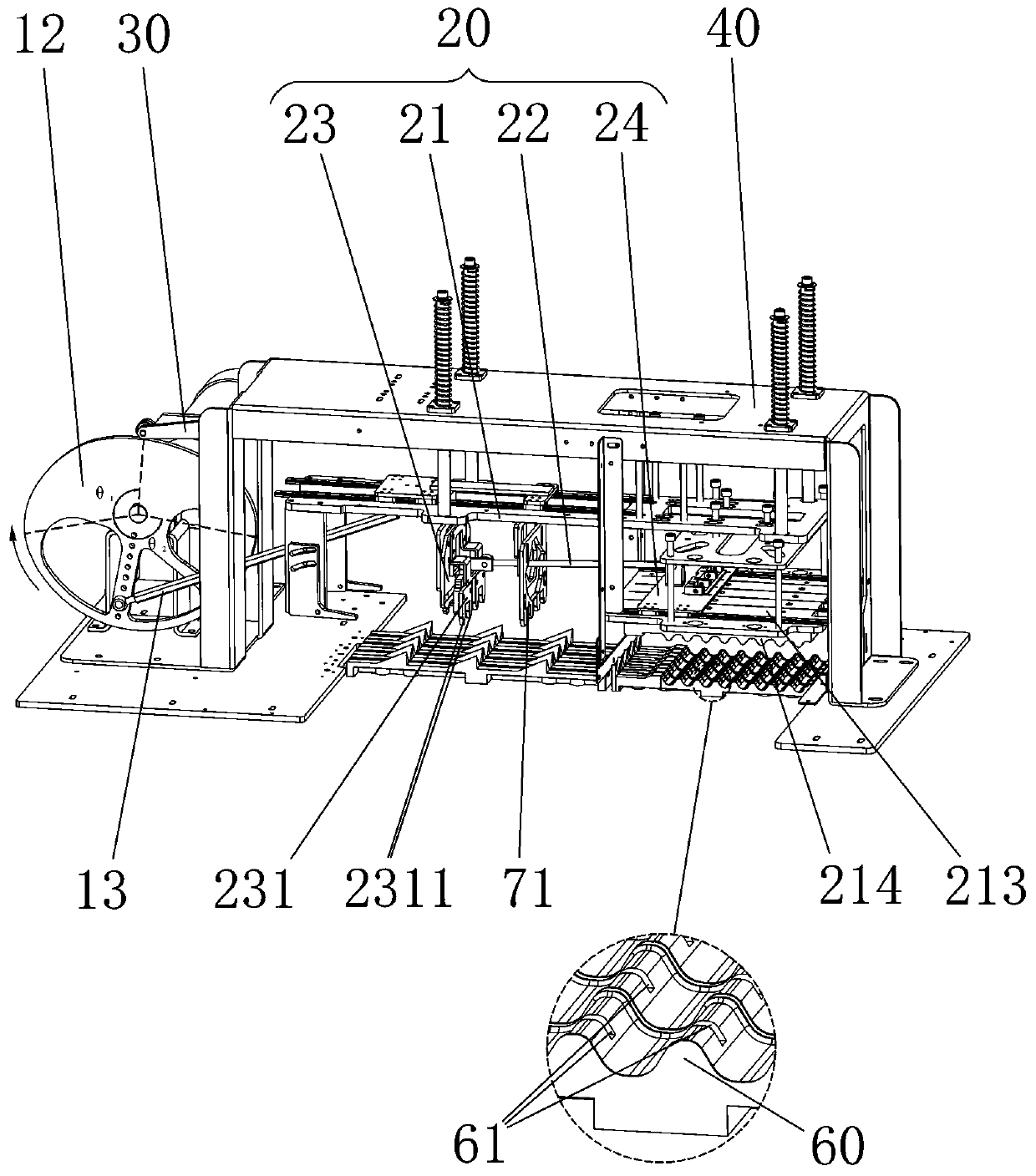

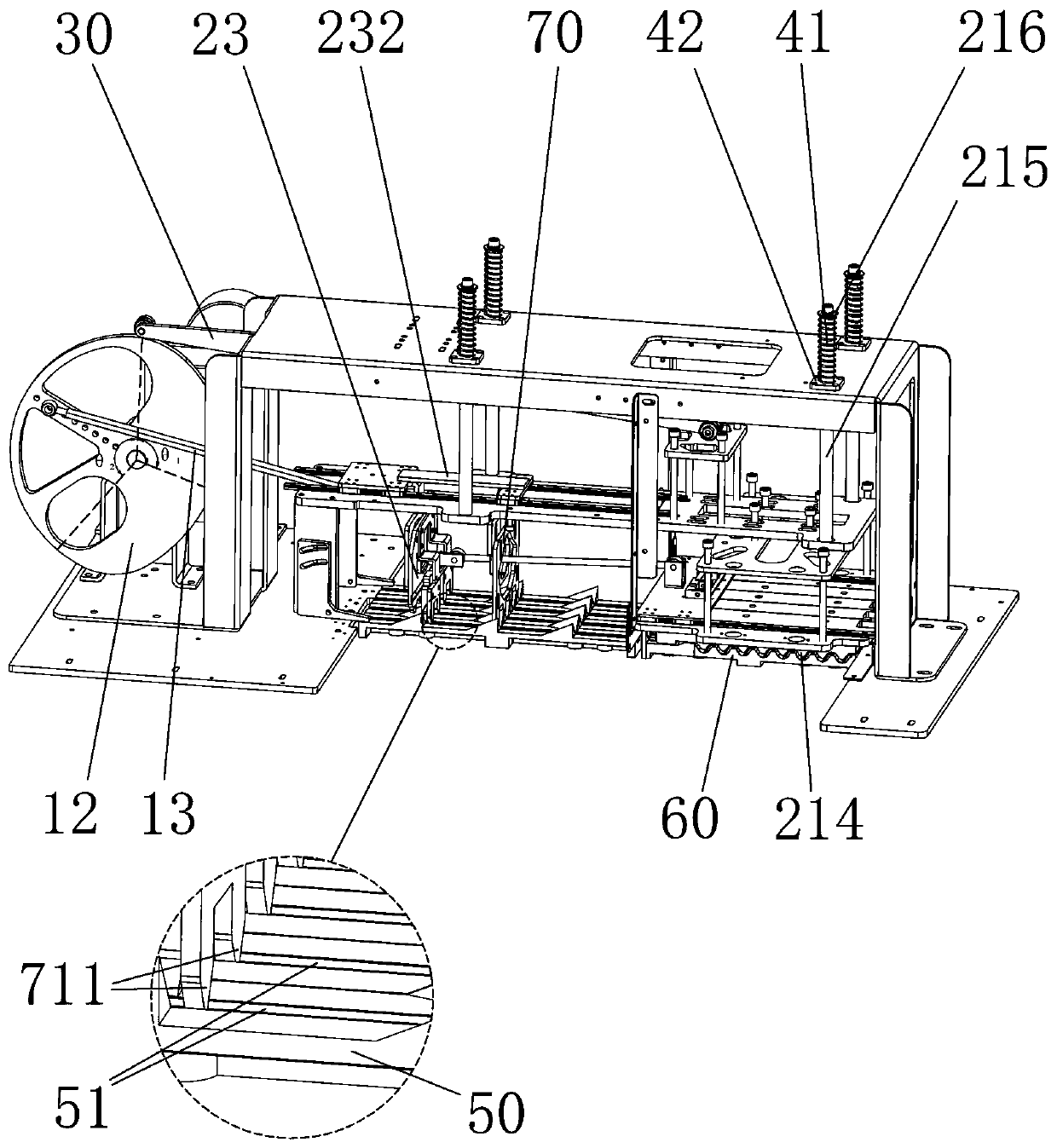

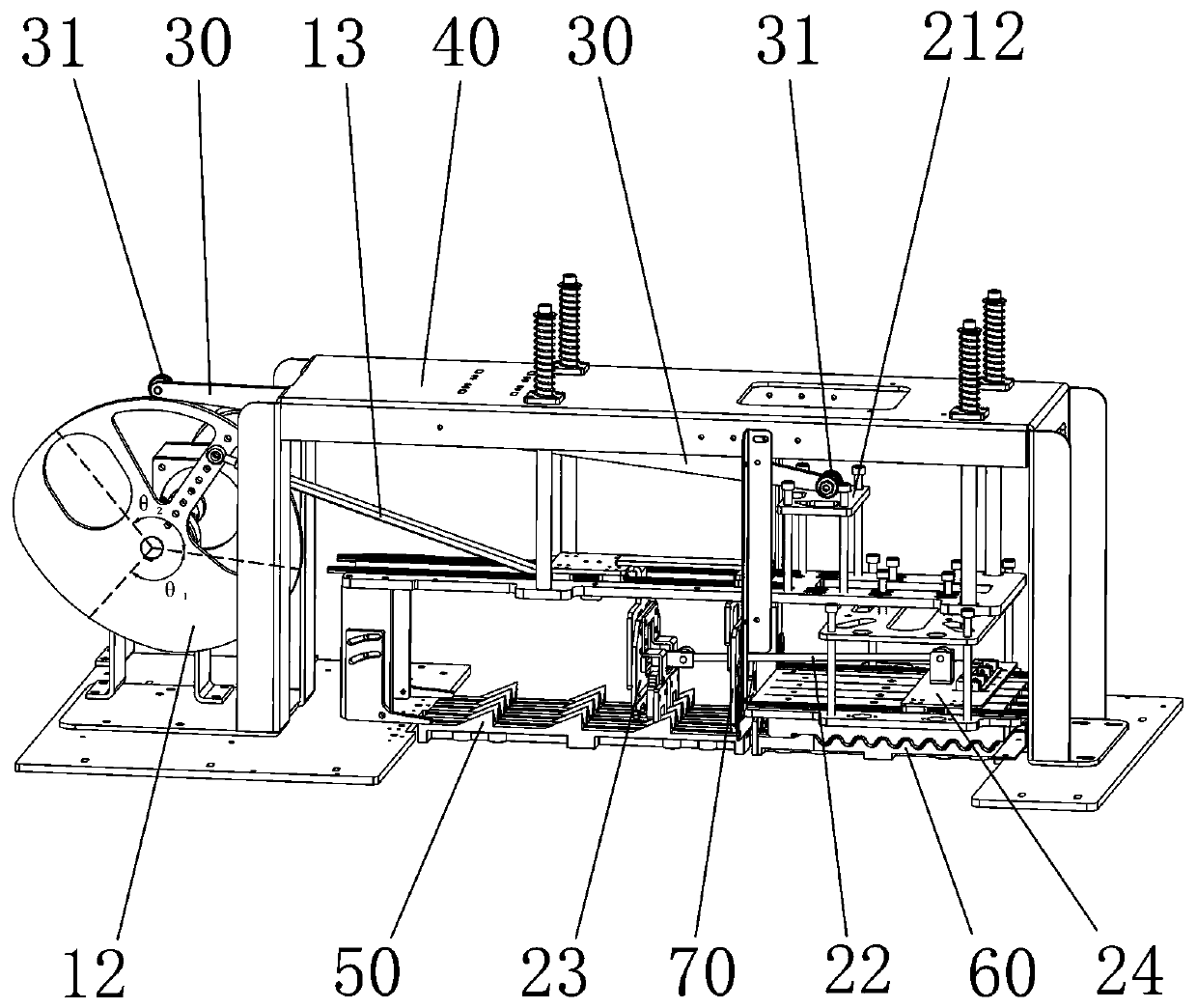

[0041] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0042] A novel threading machine that cuts through and integrates, including a driving device 10, a lifting device 20, a follower 30, a fixing frame 40, a guide block 50, and a lower anvil 60, and the follower 30 is arranged on the At the fixed frame 40, the driving device 10 drives the lifting device 20 to carry out lifting movement through the follower 30, the follower 30 is arranged above the lifting device 20, and the guide block 50 and The lower cutting boards 60 are all arranged below the lifting device 20;

[0043] The driving device 10 includes a driving motor 11 and a cam 12, the lifting device 20 includes a lifting seat 21, the follower 30 is hinged at a fulcrum 211 of the fixed frame 40, and the follower 30 Deflection around the fulcrum 211, one end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com