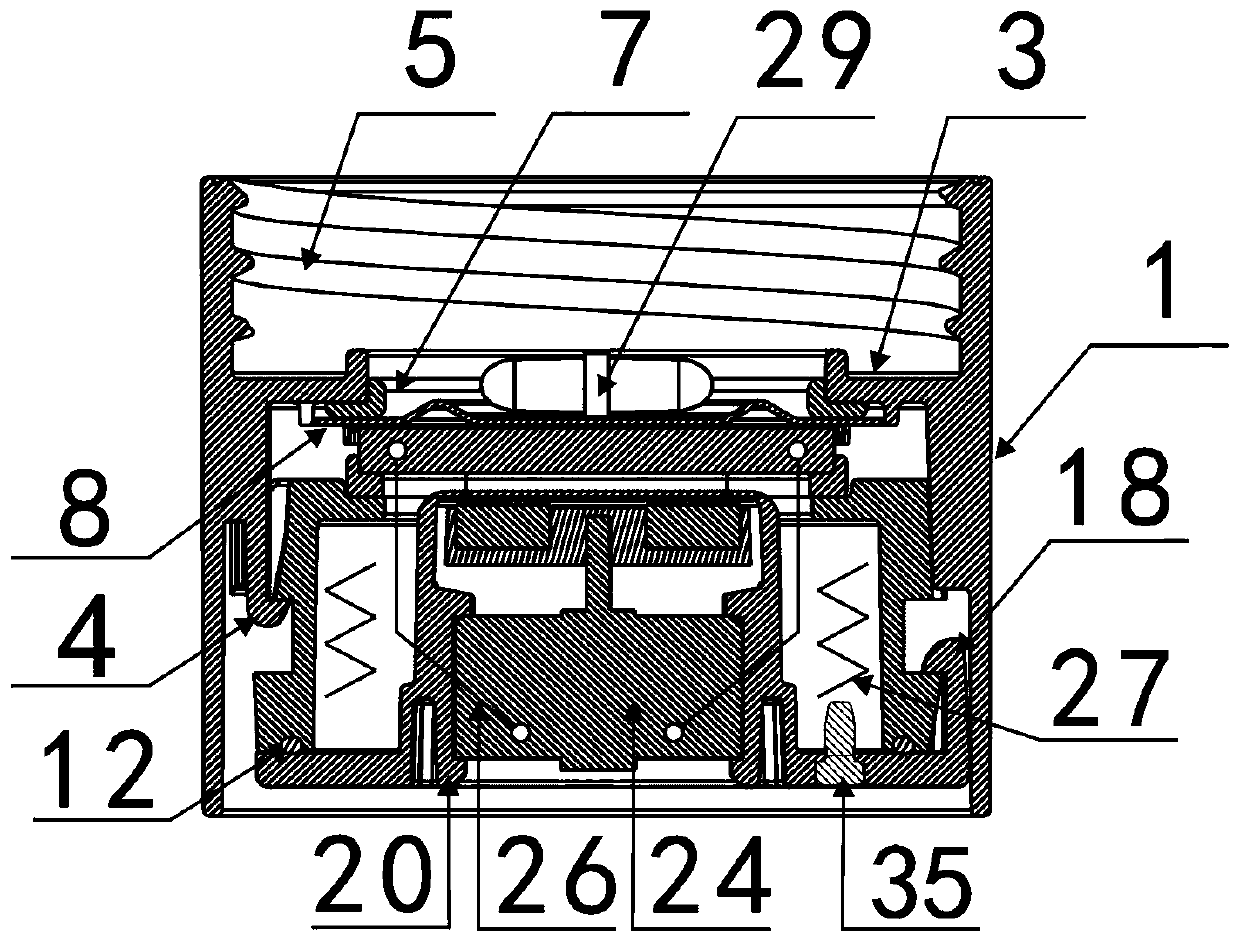

Heat energy power supply stirrer

A stirrer and thermal energy technology, applied in the field of stirring cups, can solve the problems of high use cost, high manufacturing cost, narrow interlayer space, etc., and achieve the effect of simple manufacture and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

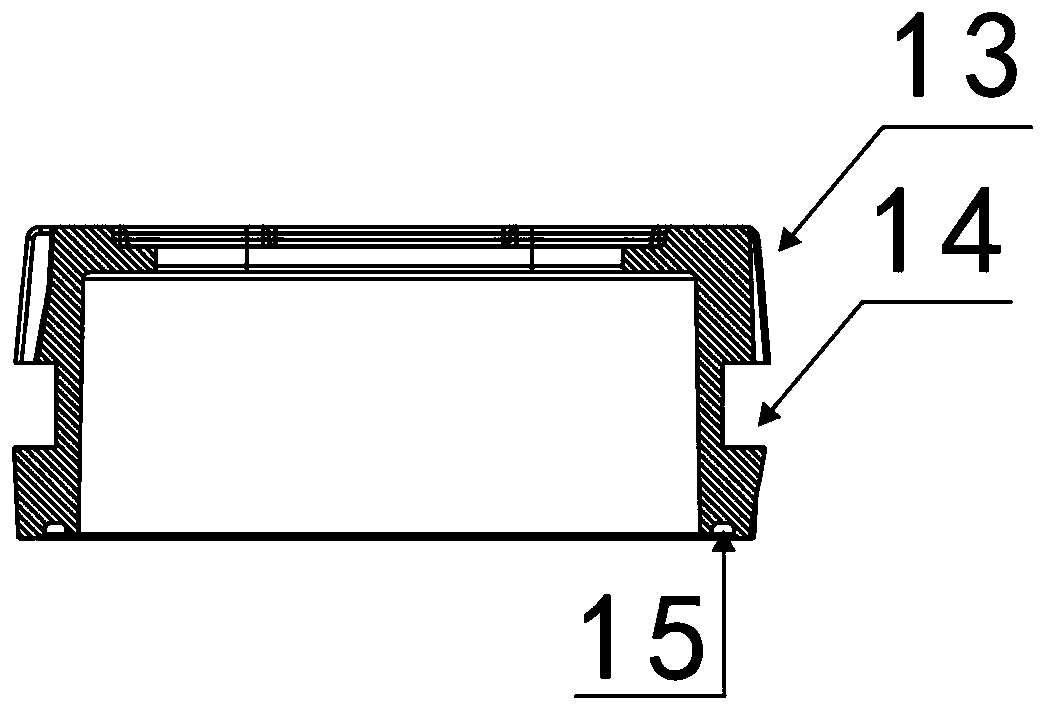

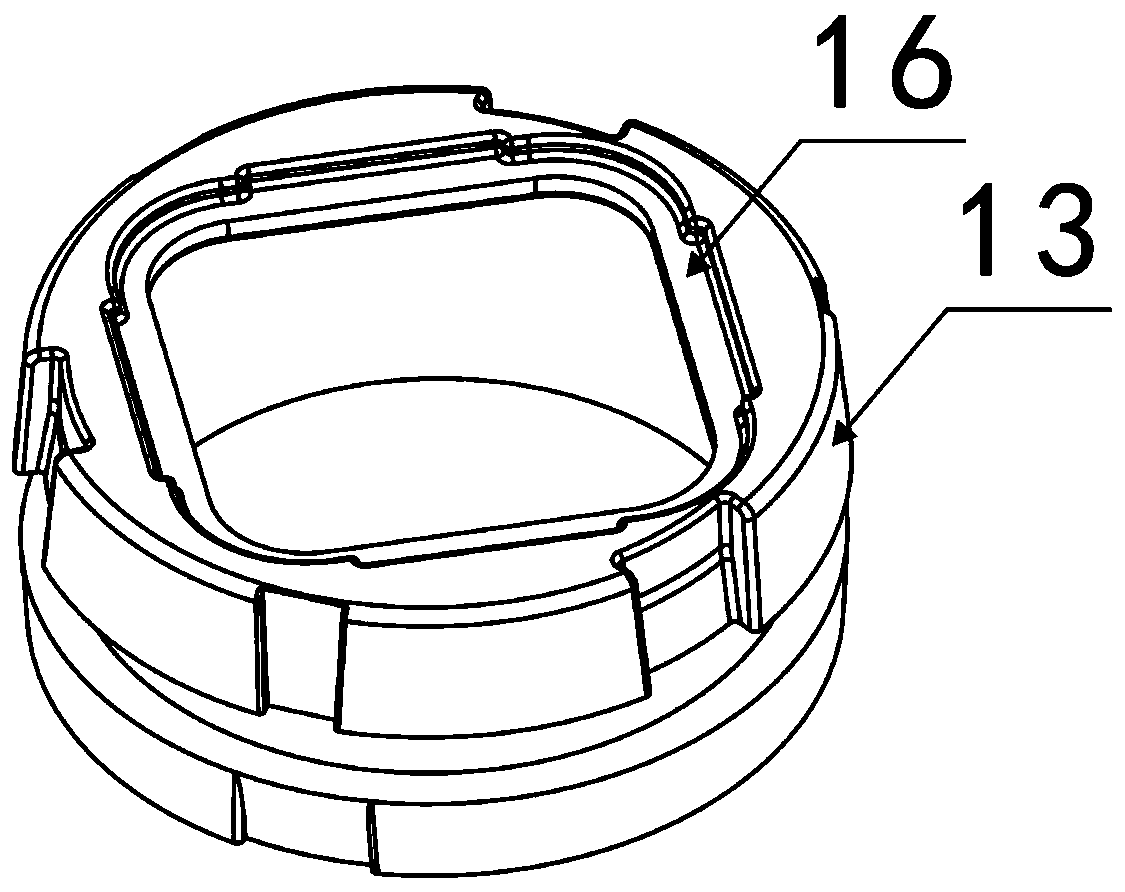

Method used

Image

Examples

Embodiment 1

[0059] With the heat-powered stirrer described in the present invention, the upper cup body can be a feeding bottle body 31, which can be used for automatic stirring when making milk powder for babies.

Embodiment 2

[0061] With the heat-powered stirrer described in the present invention, the upper cup body can be an ordinary cup cup body 34, which can be applied to automatic stirring when brewing in daily life.

Embodiment 3

[0063] Using the heat-powered agitator described in the present invention, the upper part of the agitator body 1 can be any container with a lower thread 32 that can be installed with the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com