Automatic cement gum preparation device for blending, stirring and bagging materials according to formula

A technology for making devices and cement, which is applied to mixers with rotating stirring devices, mixer accessories, packaging, etc., which can solve the problems of high net content of inhalable particulate matter, large manpower and time costs, and difficulty in strict installation standards, etc., to prevent Dust scattered, work efficiency improved, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

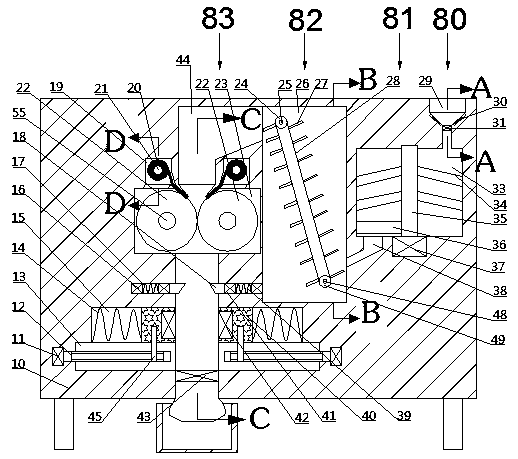

[0021] Combine below Figure 1-5 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The front, back, left, right, up, and down directions of the view direction are the same, figure 1 It is the front view of the device of the present invention, figure 1 The directions shown are consistent with the front, back, left, right, up, and down directions of the front view direction of the device of the present invention.

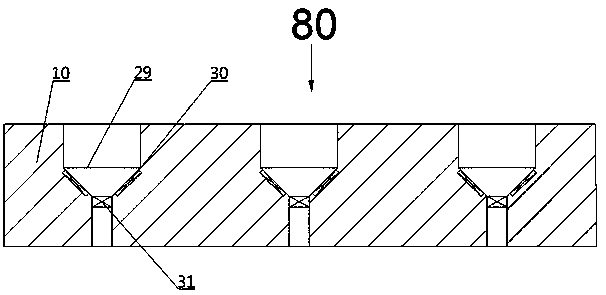

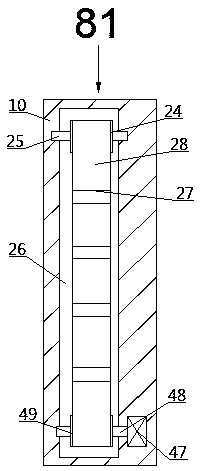

[0022] refer to Figure 1-5 , according to an embodiment of the present invention, an automatic production device for mixing and bagging cement according to a formula, comprising a fuselage 10, the top surface of the fuselage 10 is provided with a hopper 29 with an upward opening, and the hopper 29 is provided with a The batching part 80 of the formula batching, the batching part 80 includes the first weight sensor 30 used to measure the batching weight fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com