A composite crusher liner device

A crusher and composite technology, which is applied in the field of composite crusher liner devices, can solve the problems of increasing the labor load of the user, and affecting the crushing efficiency of the composite crusher due to the time of disassembly and reinstallation, so as to increase the labor load and shorten the The time of the angle, the effect of improving the crushing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

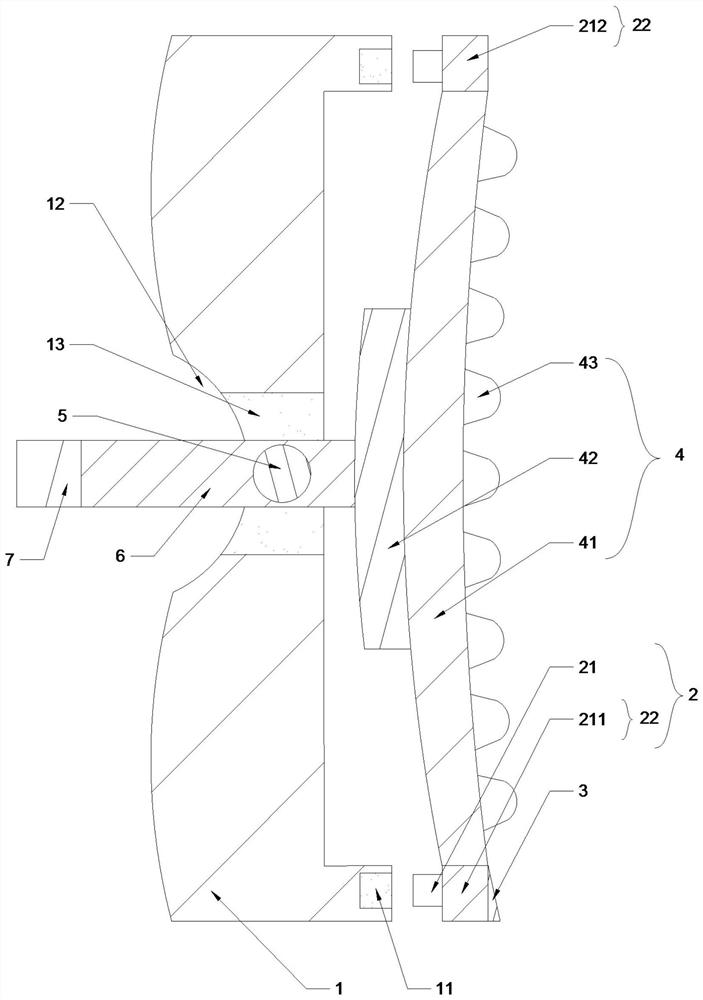

[0028] see Figure 1~3 , a composite crusher liner device, including a liner 4, an adjustment rod 6 is provided at the end of the liner 4 away from the working surface, an adjustment block 1 is provided on the adjustment rod 6, and an accommodation adjustment rod is provided on the adjustment block 1 6 of the adjustment hole 13, the adjustment hole 13 is provided with a fixed shaft 5 for the rotation of the adjustment rod 6, and the fixed shaft 5 runs through the adjustment rod 6, the aperture of the adjustment hole 13 is greater than the diameter of the adjustment rod 6, and the adjustment block 1 is provided with a The adjusting groove 12 for the movement of the adjusting rod 6 is connected with the adjusting hole 13 , the fixing device 2 is arranged on the liner 4 , and the locking groove 11 for engaging the fixing device 2 is arranged on the adjusting block 1 .

[0029] In the present invention, the user can adjust the angle of the liner 4 according to the specific needs. ...

Embodiment 2

[0031] see Figure 1~3 , a composite crusher liner device, including a liner 4, an adjustment rod 6 is provided at the end of the liner 4 away from the working surface, an adjustment block 1 is provided on the adjustment rod 6, and an accommodation adjustment rod is provided on the adjustment block 1 6 of the adjustment hole 13, the adjustment hole 13 is provided with a fixed shaft 5 for the rotation of the adjustment rod 6, and the fixed shaft 5 runs through the adjustment rod 6, the aperture of the adjustment hole 13 is greater than the diameter of the adjustment rod 6, and the adjustment block 1 is provided with a The adjusting groove 12 for the movement of the adjusting rod 6 is connected with the adjusting hole 13 , the fixing device 2 is arranged on the liner 4 , and the locking groove 11 for engaging the fixing device 2 is arranged on the adjusting block 1 .

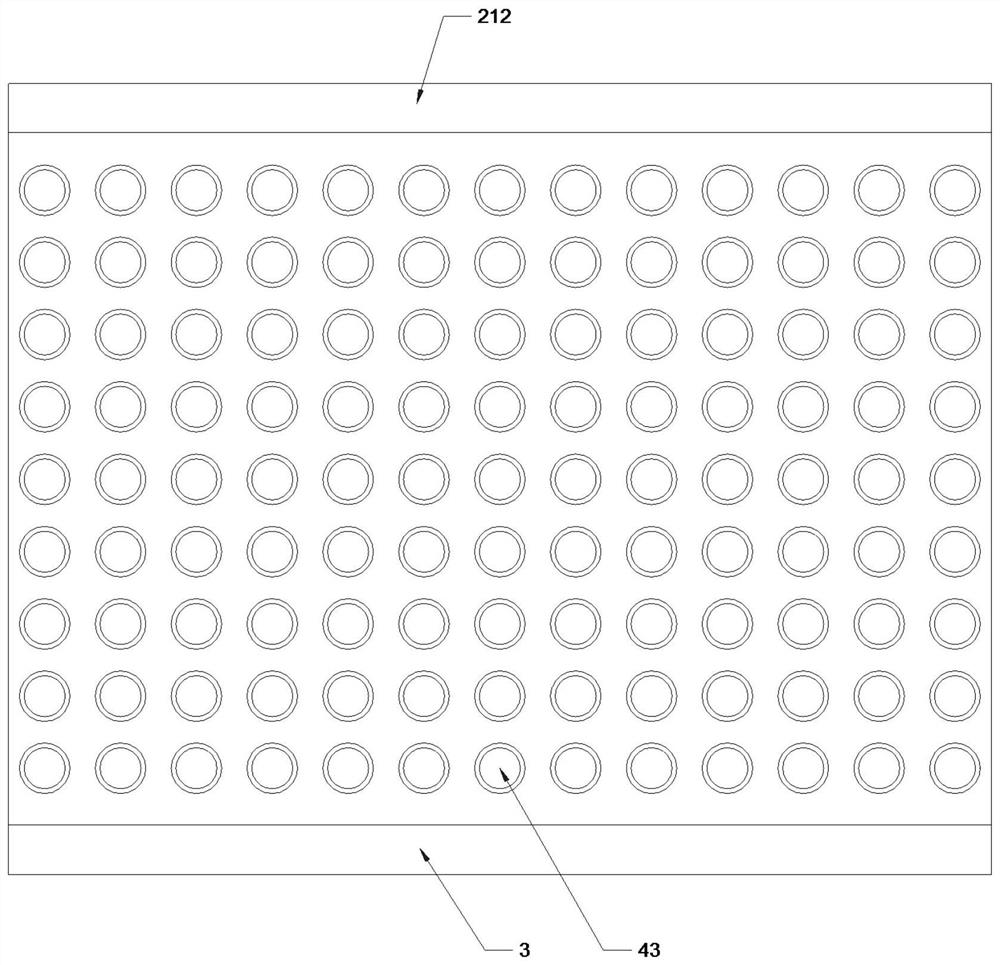

[0032] The fixing device 2 includes a fixed arc block 22, the two ends of the lining plate 4 are respectively p...

Embodiment 3

[0036] see Figure 1~3 , a composite crusher liner device, including a liner 4, an adjustment rod 6 is provided at the end of the liner 4 away from the working surface, an adjustment block 1 is provided on the adjustment rod 6, and an accommodation adjustment rod is provided on the adjustment block 1 6 of the adjustment hole 13, the adjustment hole 13 is provided with a fixed shaft 5 for the rotation of the adjustment rod 6, and the fixed shaft 5 runs through the adjustment rod 6, the aperture of the adjustment hole 13 is greater than the diameter of the adjustment rod 6, and the adjustment block 1 is provided with a The adjusting groove 12 for the movement of the adjusting rod 6 is connected with the adjusting hole 13 , the lining plate 4 is provided with the fixing device 2 , and the adjusting block 1 is provided with a slot 11 for engaging the fixing device 2 .

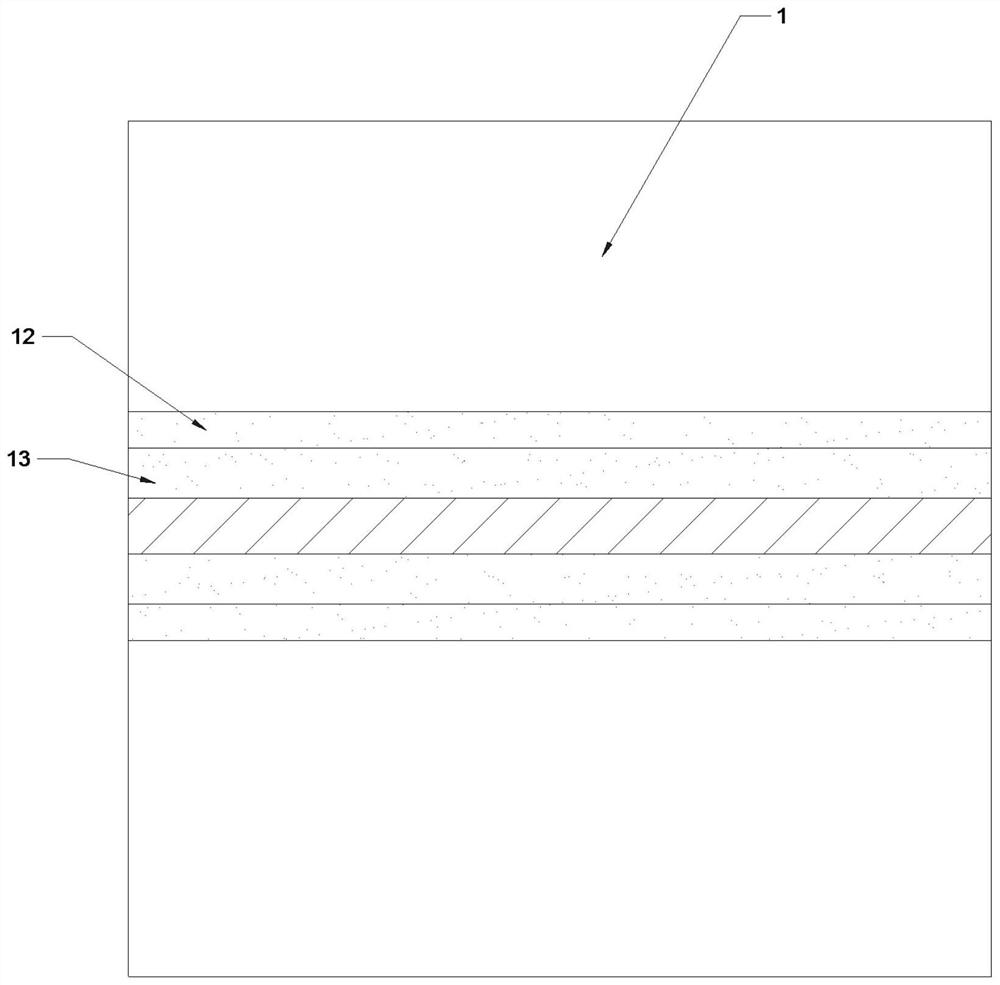

[0037]The liner 4 includes an arc plate 41 and a fixed support block 42. The working surface of the arc plate 41...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com