Energy-saving and environment-friendly weaving machine device with function of adsorbing fabric floccules, and using method thereof

An energy-saving and environmental protection, floc technology, applied in the direction of electrostatic cleaning, textile and papermaking, chemical instruments and methods, etc., can solve the problems of consuming manpower and material resources, affecting industrial production, etc., to save space, save manpower, and reasonable structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

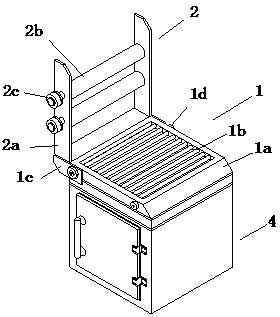

[0040] A method for using an energy-saving and environment-friendly textile machine device for absorbing fabric flocs. Using the above-mentioned device, the fabric is inserted through the closed loop formed by the top arm 2b and the bottom arm 2c arranged between two side arms 2a. The frame provides power for the rollers through the motor 2d, and then rotates in different directions through the two rollers 2a provided between the two side arms 2a, so that the fabric inserted on the closed frame can be continuously transported to the electrostatic adsorption On the device 1, the adsorption of the fabric flocs is carried out through the electrostatic adsorption device 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com