Correction machine at front end of container

A container and calibrating machine technology, applied in the field of container maintenance, can solve the problems of low efficiency, high noise, high labor intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Typical implementations embodying the features and advantages of the present application will be described in detail in the following description. It should be understood that the present application can have various changes in different embodiments without departing from the scope of the present application, and that the descriptions and illustrations therein are illustrative in nature and not limiting this application.

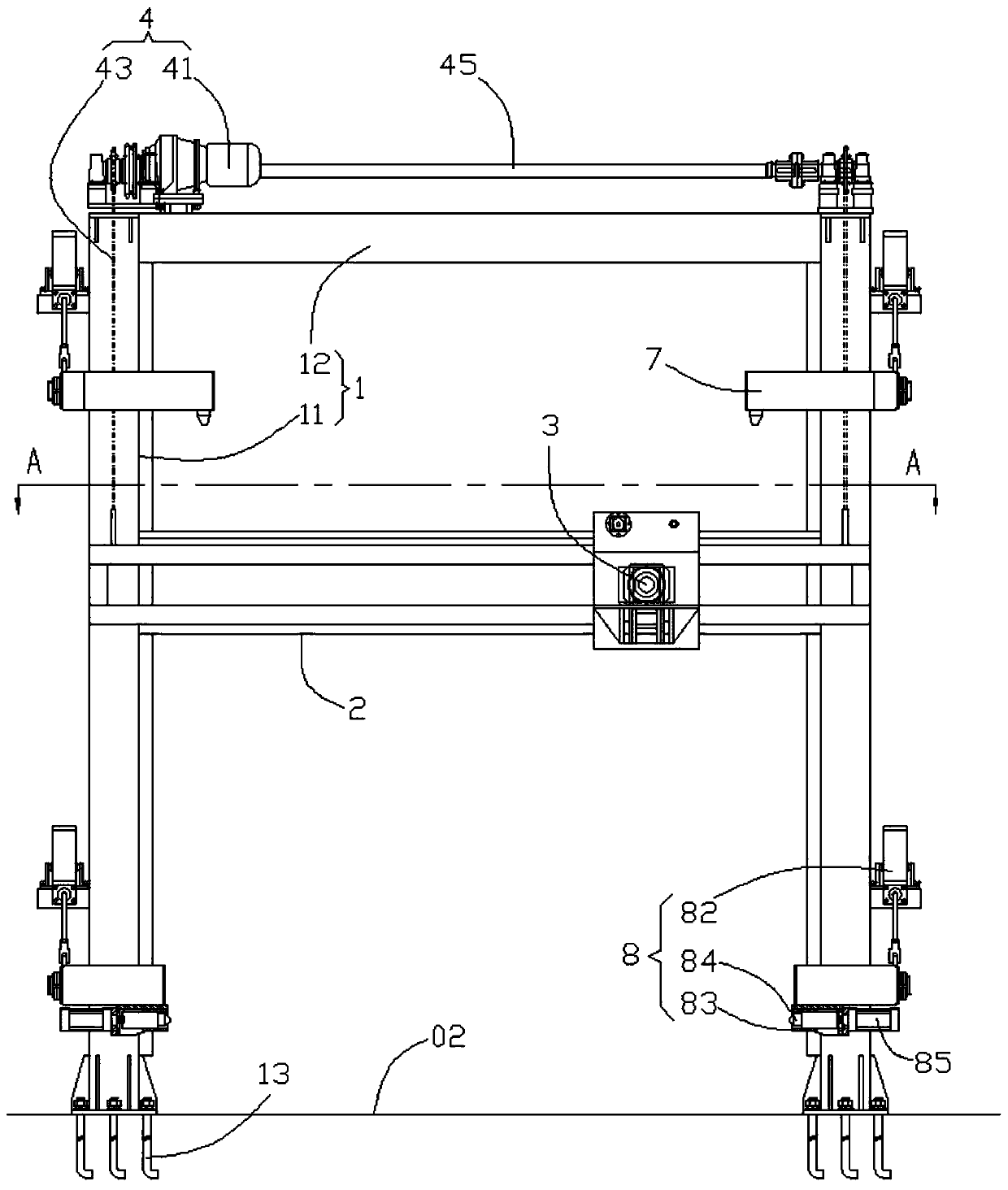

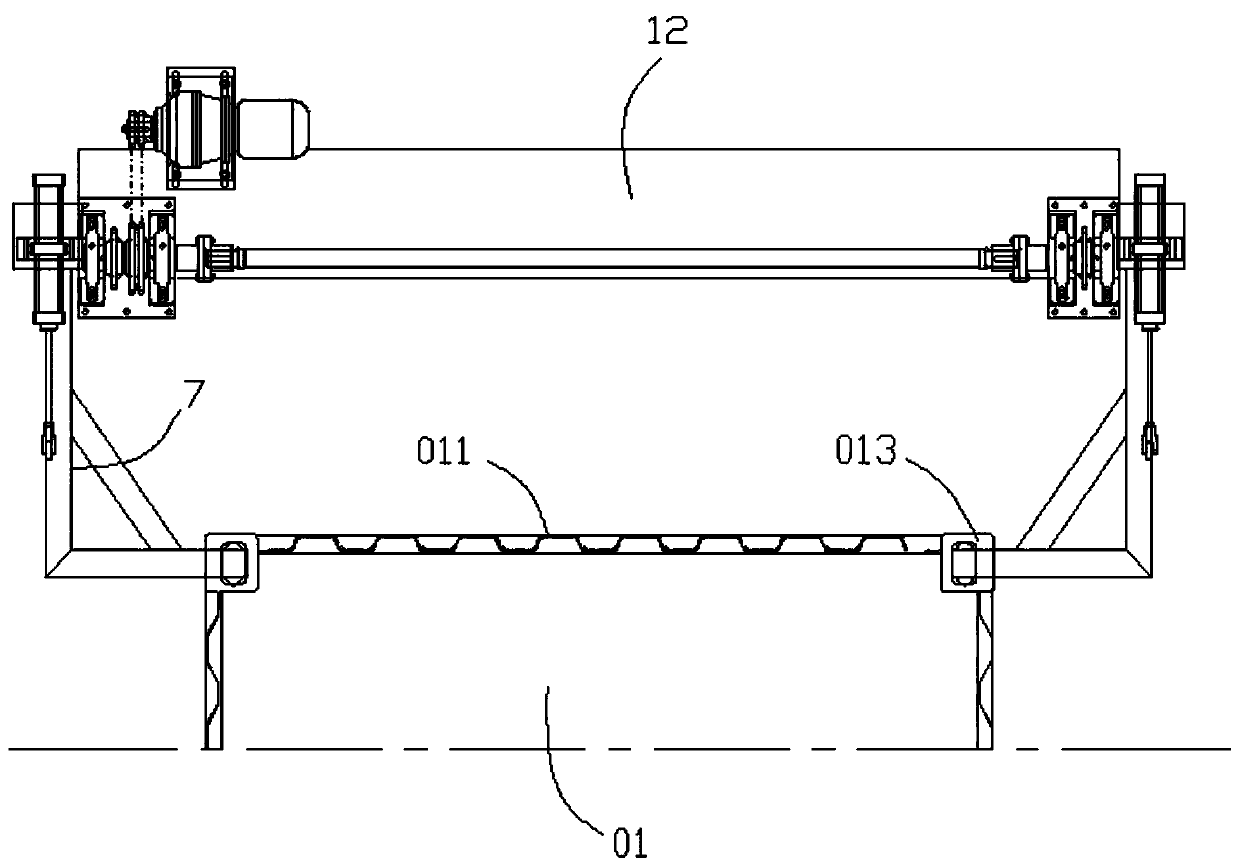

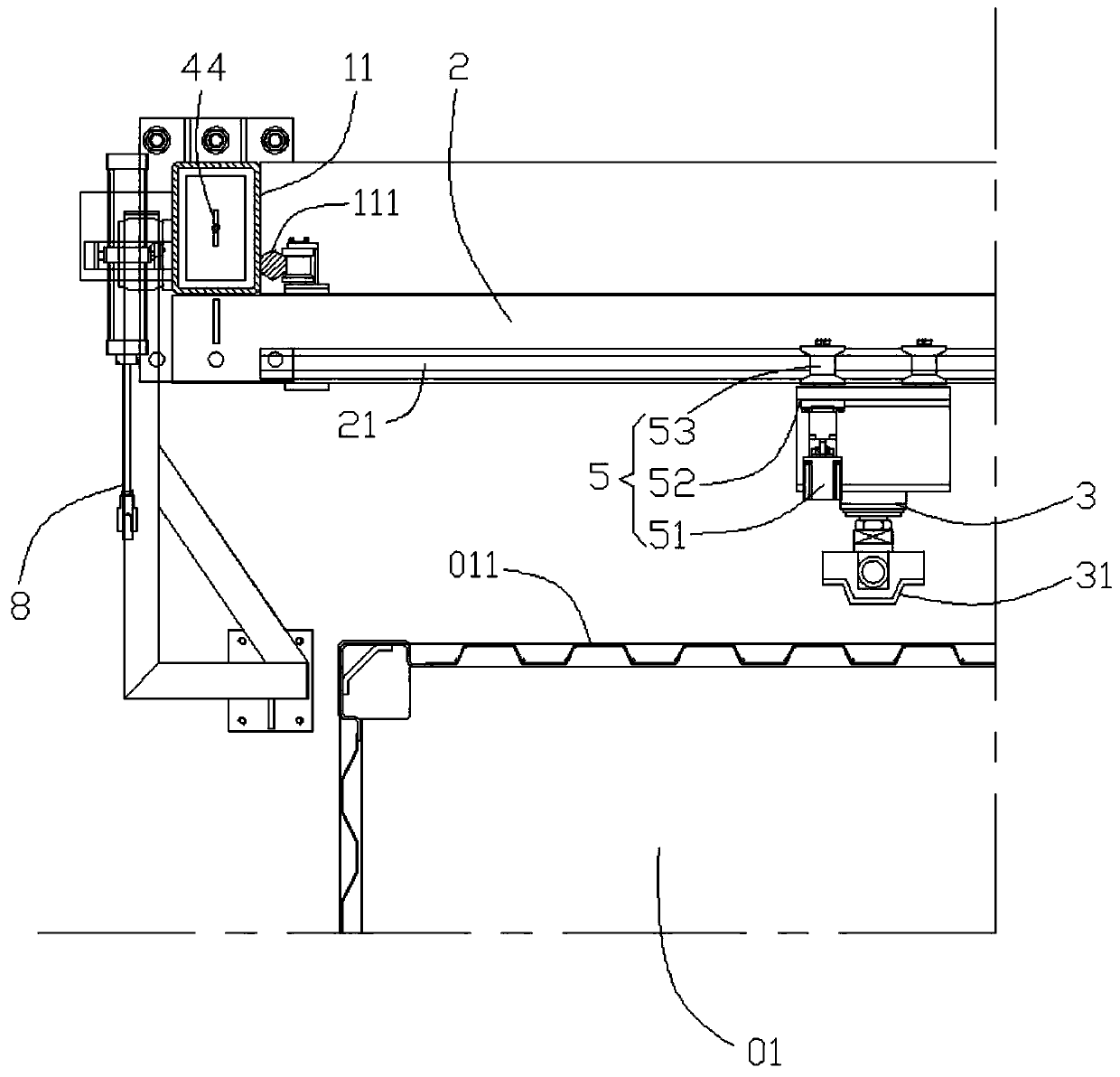

[0037] refer to Figure 1 to Figure 4 The embodiment of the present application provides a container front end correction machine, including a frame 1, a lifting beam 2, a hydraulic cylinder 3, a lifting drive mechanism 4, a lateral movement drive mechanism 5, a hook claw 6, an upper positioning mechanism 7 and a lower positioning mechanism 8.

[0038] The frame 1 includes two vertical beams 11 arranged at intervals and a fixed beam 12 fixedly connecting the two vertical beams 11 from the top, and the two vertical beams 11 are fixed to the ground 02...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com