Stamping device for automotive body accessory processing

A technology for automobile body and stamping device, applied in the field of stamping device, can solve the problems of stamping part error, plate inclination, etc., and achieve the effect of avoiding skew and facilitating adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

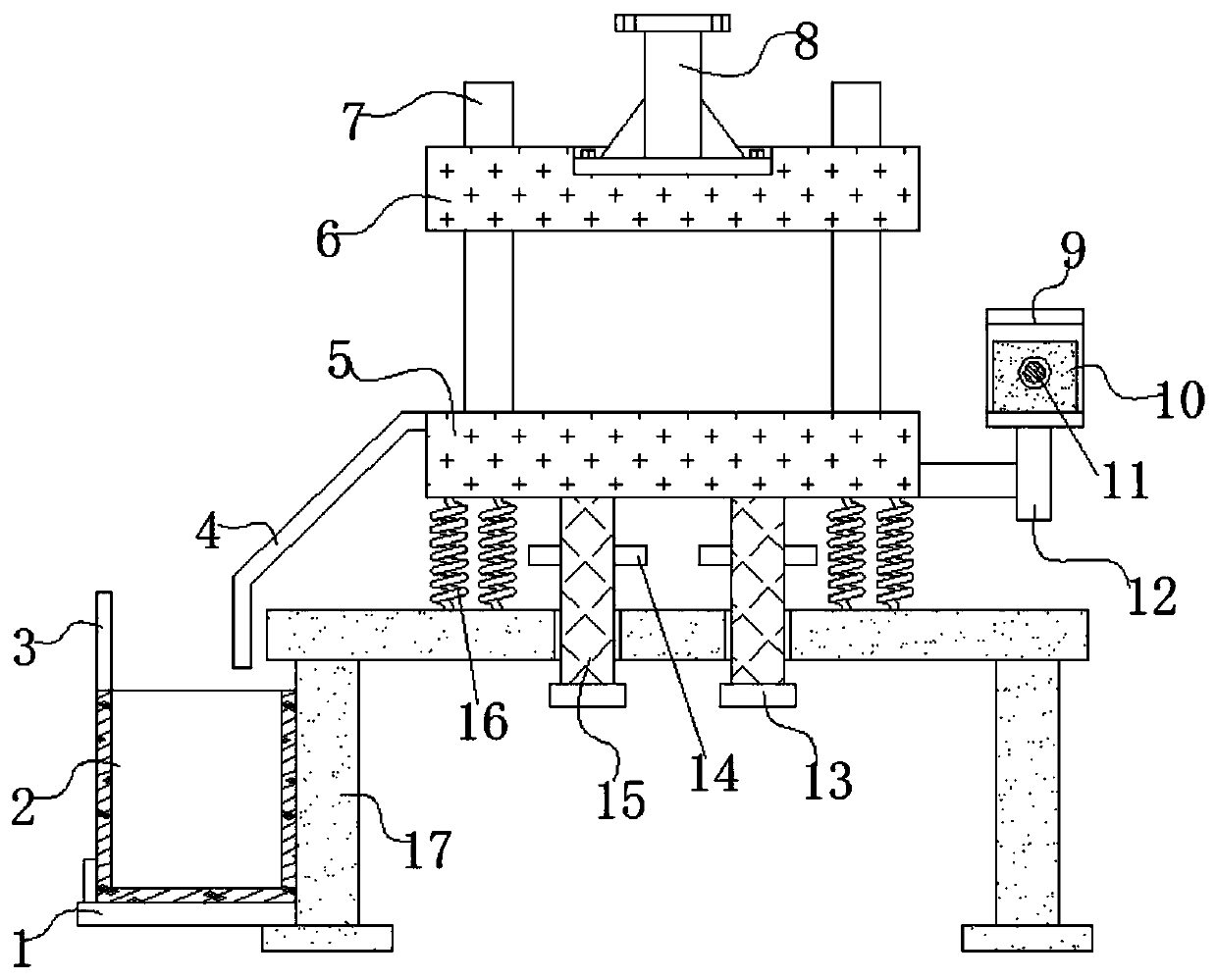

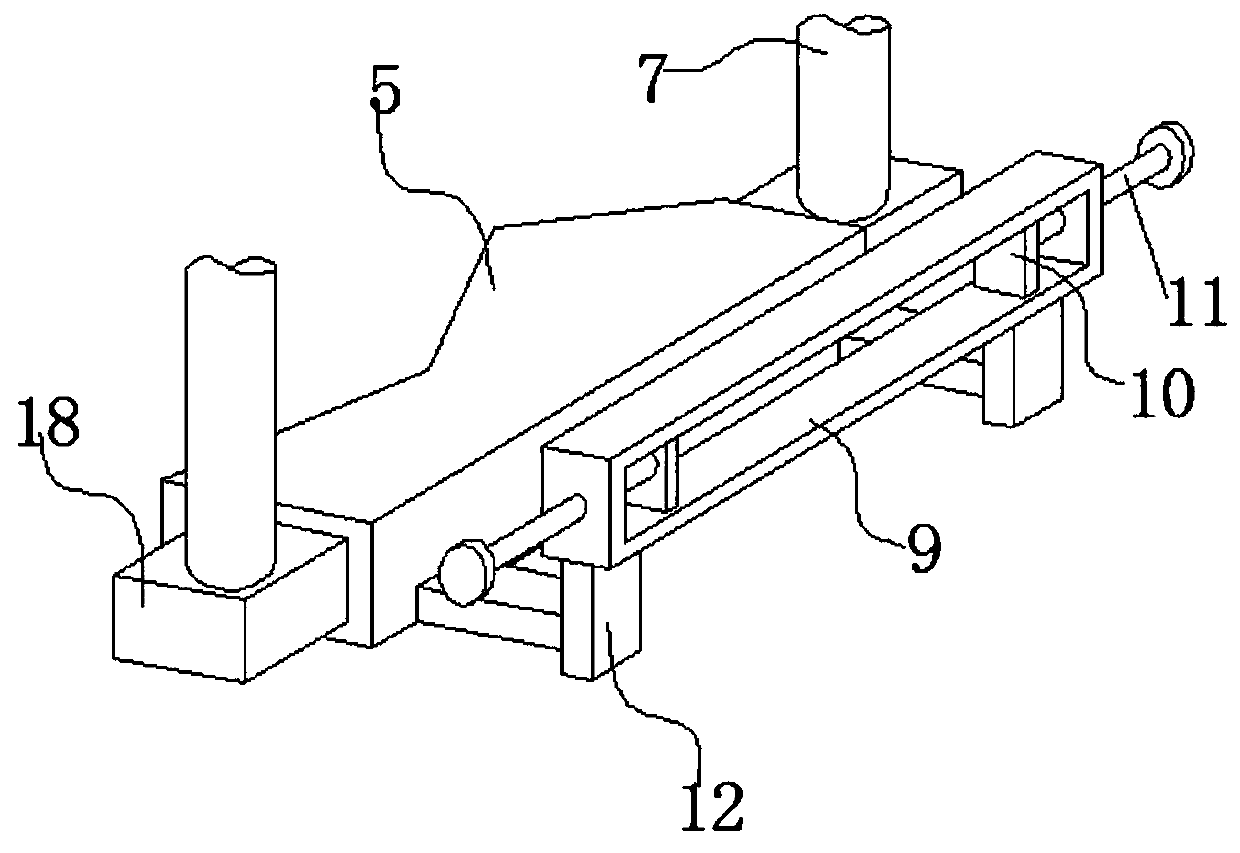

[0022] refer to figure 1 and figure 2 , a stamping device for processing automobile body parts, comprising a fixed mold base 5, a movable mold base 6 and a workbench 17, the top of the workbench 17 is welded with multiple sets of springs 16, and the top of the springs 16 is welded to the bottom of the fixed mold base 5 , the top of workbench 17 is provided with a plurality of through holes, and column 15 is inserted in the through holes, and the top of column 15 is welded with the bottom of fixed mold base 5, and the outer wall of column 15 is welded with limit plate 14, limit plate 14 is located above the workbench 17, the bottom of the column 15 is welded with a backing plate 13, the outer wall of one side of the fixed mold seat 5 is welded with two cross bars, and one end of the two cross bars is welded with a telescopic rod 12, further The telescopic rod 12 is a manual lockable telescopic rod. The telescopic rod 12 is convenient for the staff to adjust the height of the ...

Embodiment 2

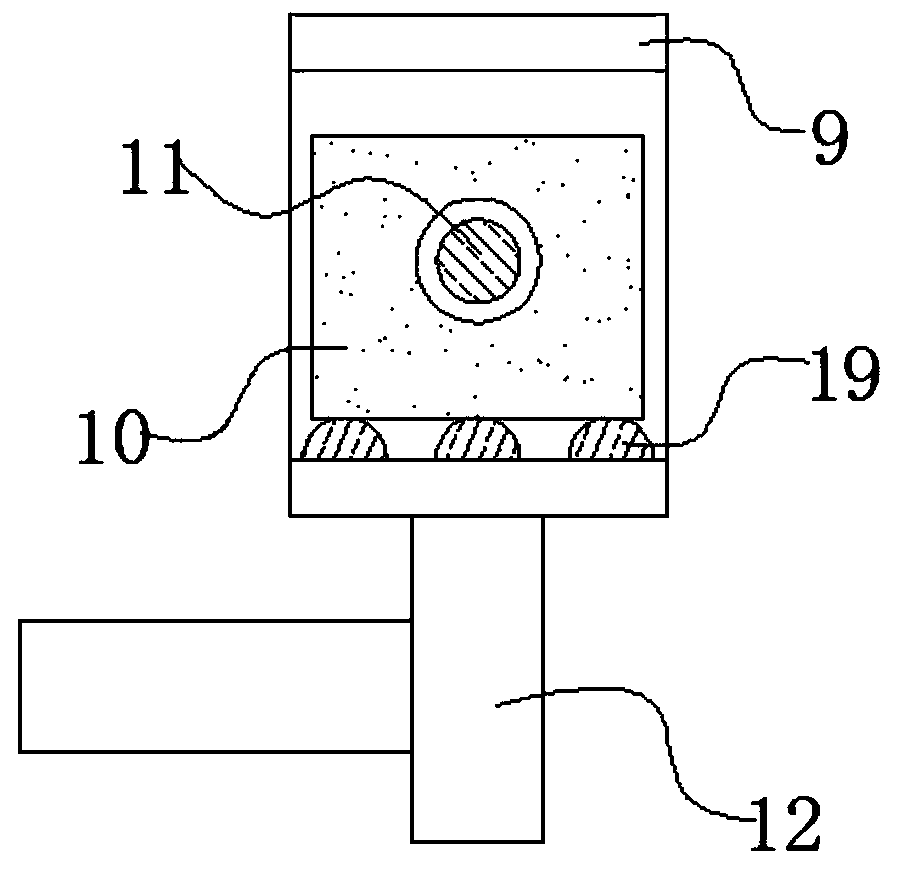

[0029] refer to image 3 , a stamping device for processing automobile body parts. Compared with Embodiment 1, the main difference of this embodiment is that in this embodiment, the bottom inner wall of the rectangular frame 9 is welded with a plurality of horizontal bars 19, and the end faces of the horizontal bars 19 are half Round, the bottom of the side block 10 is in contact with the top of the bar 19 .

[0030] Working principle: when in use, the bottom of the plate is located on the horizontal bar 19, because the end face of the horizontal bar 19 is semicircular, so the contact area between it and the plate is small, which reduces the friction force when the plate moves.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap