Device for manufacturing powder plasticizing floor

A technology for making devices and floors, which is applied in the field of house decoration materials, can solve problems such as low efficiency and cumbersomeness, and achieve the effects of safe and rapid process, high degree of integration, and high energy utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

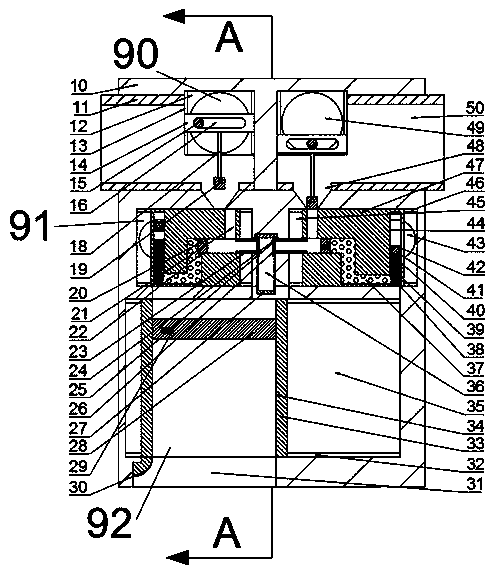

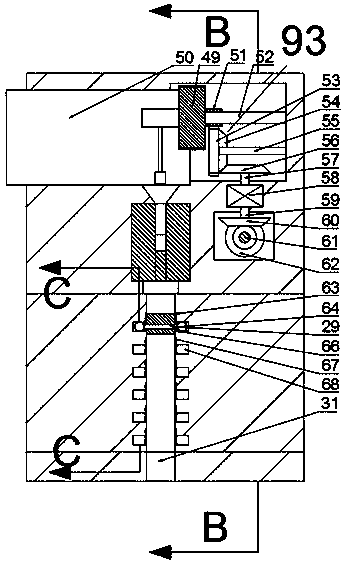

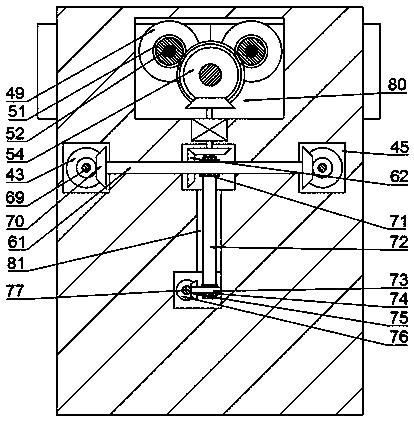

[0022] Combine below Figure 1-4 The present invention will be described in detail. For the convenience of description, the orientations mentioned below are now specified as follows: figure 1 The vertical, horizontal, front and rear directions of the projection relationship are the same.

[0023] Attached Figure 1-4 The manufacturing device of a powder plasticized floor includes a body 10, and the body 10 includes a left-right symmetrical feeding cavity 50, and the left-right symmetrical feeding cavity 50 is provided with intermittent extrusion by a piston. The wood powder and viscose are pushed into the feeding mechanism 90 of the next mechanism. The two end walls of the feeding cavity 50 are fixed with feeding ports 11, and the rear wall of the feeding cavity 50 is fixed with a fixing block 11 , The fixed block 11 is rotatably provided with a first rotating wheel 49, the fixed block 11 is fixedly provided with a first sliding groove 13 and the first sliding groove 13 is provi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap