Conveying method for main drive of shield machine in narrow and small space

A narrow space, the main drive technology, applied in the direction of conveyor, transportation and packaging, etc., can solve the main drive can not turn over into a horizontal state, damage to equipment and personnel, difficult transportation and other problems, to achieve low construction cost, convenient and stable materials good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

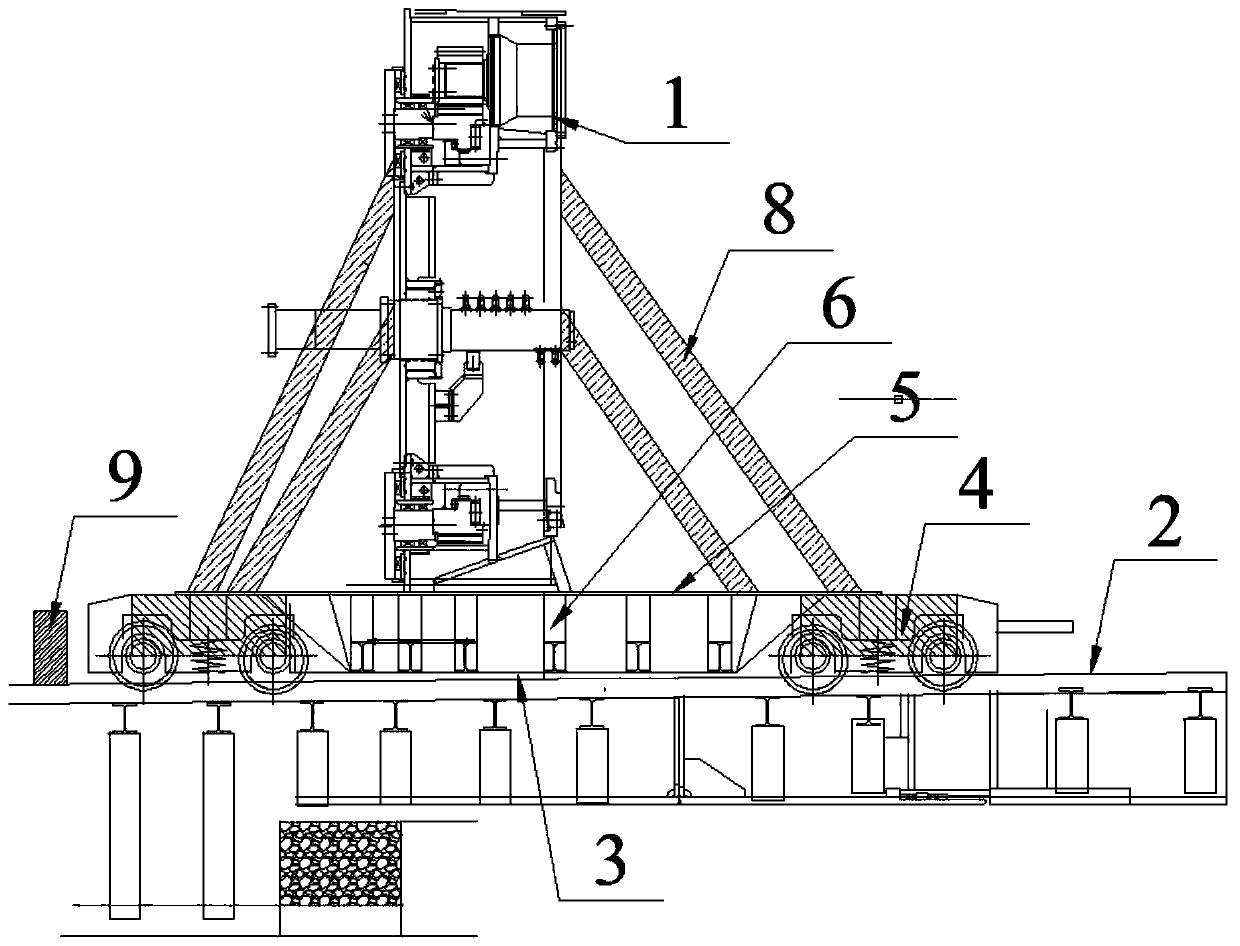

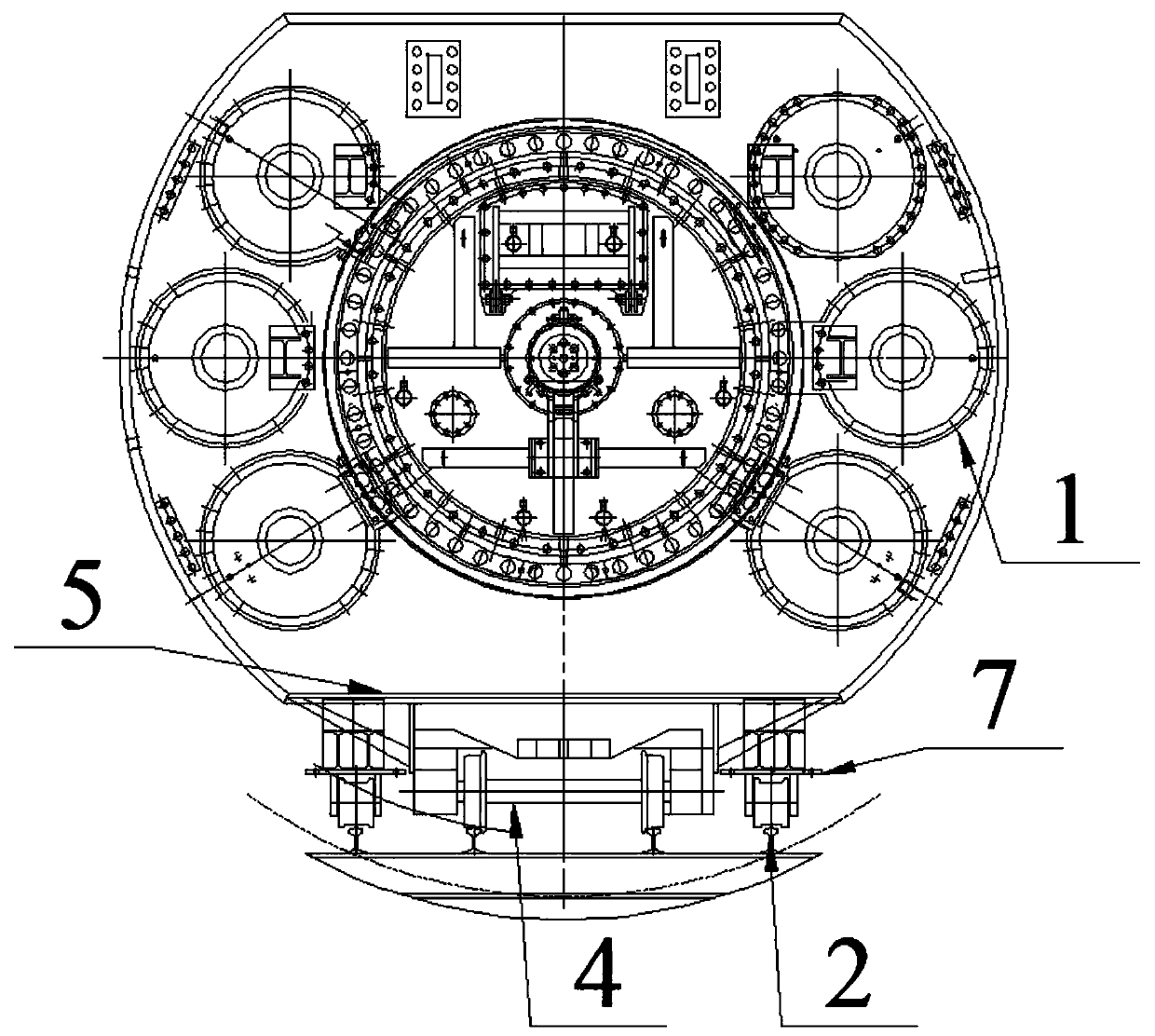

[0027] like Figures 1 to 2 , a method for conveying the main drive of a shield machine in a narrow space. The conveying device in this embodiment is used for conveying the main drive 1 of a shield machine in a narrow tunnel. Among them, it includes a support platform which is located under the main drive 1 and plays a supporting role. Below the support platform is laid a guide rail 2 arranged along the traveling direction. The support platform is slidably connected to the guide rail. Driven traction device.

[0028] like Figures 1 to 2 As shown, the traction device of this embodiment includes a frame 3 located below the main drive and traction units 4 located at the front and rear ends of the frame 3 . In fact, the traction device in this embodiment is the frame structure of the muck truck, and the frame 3 is used to carry the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com