Intelligent control method and device for sintered fuel drying end point

A technology of intelligent control and fuel, which is applied in the direction of dryers for static materials, heating devices, drying solid materials, etc., and can solve problems such as high safety risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] see Figure 6 , is a flowchart of an intelligent control method for the drying end point of sintered fuel provided by this application. Such as Figure 6 As shown, the method includes:

[0037] 601. Acquire the current weight of the sintered fuel according to a preset period.

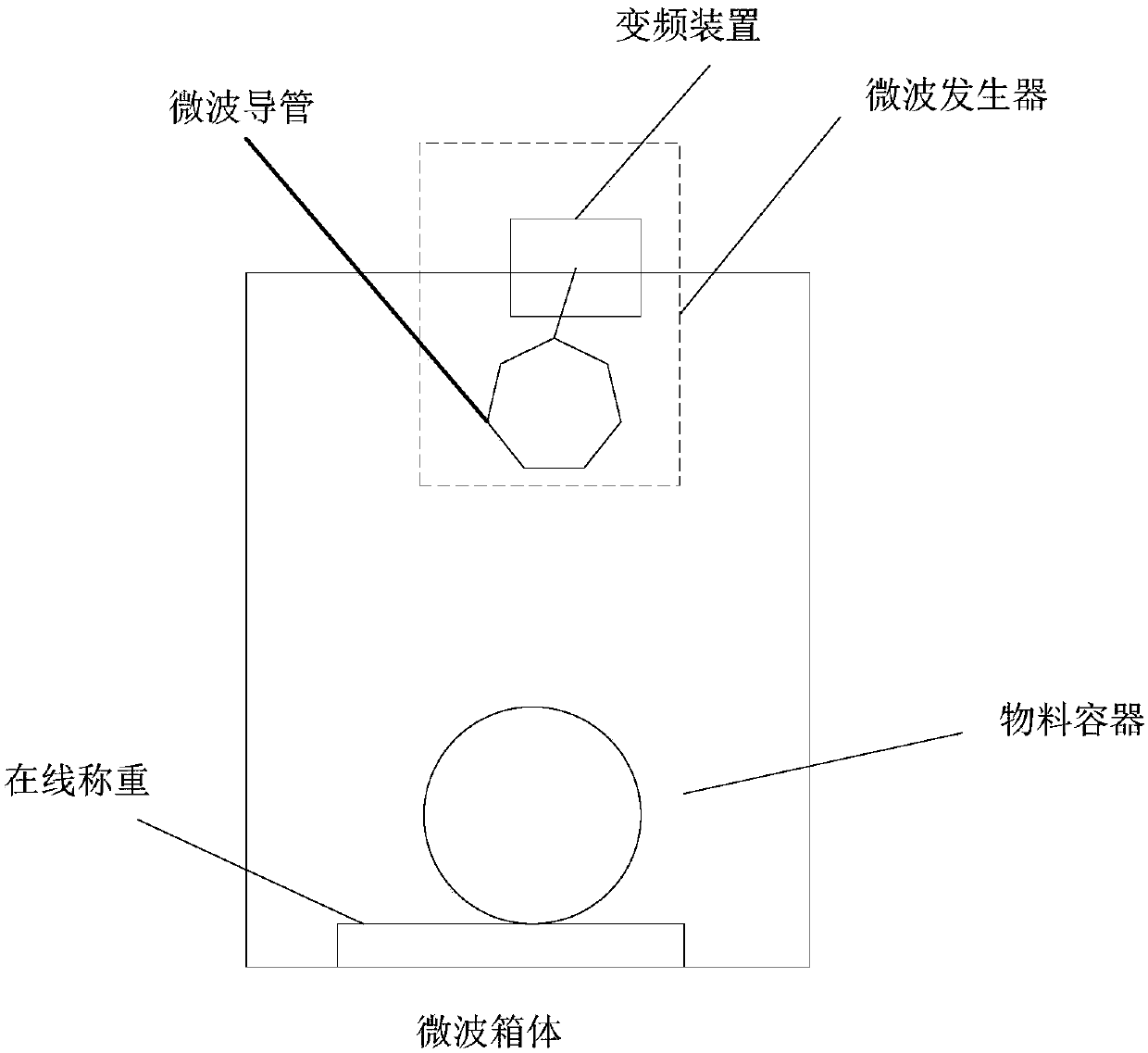

[0038] Material is a technical term in the field of production. Production enterprises are accustomed to refer to all materials that circulate in the production field other than the final product, including fuel, parts, semi-finished products, outsourcing parts, and leftovers, waste materials and various wastes that are inevitably generated during the production process. ". Obtaining the current weight of the sintered fuel is during the microwave drying process of the sintered fuel. When the microwave drying is too heavy, the current weight of the sintered fuel is continuously obtained according to the preset cycle. The preset period can be determined according to the water content of the s...

Embodiment 2

[0051] see Figure 7 , is a flow chart of another intelligent control method for the drying end point of sintered fuel provided by this application. Such as Figure 7 As shown, the method includes:

[0052] 701. Obtain the initial weight of the sintered fuel.

[0053] Obtaining the initial weight of the sintered fuel before starting drying makes the calculated drying rate results more accurate. Specifically include: if a drying start instruction is received, generate a mass acquisition instruction, which is used to acquire the weight of the sintered fuel; respond to the mass acquisition instruction, find the mass of the sintered fuel at the current moment; determine the search result as the initial weight. The drying start instruction can be generated by the user operating the external button of the microwave drying equipment, or it can be sent remotely by the user through a wireless terminal, or it can be automatically generated after the previous processing of the sintere...

Embodiment 3

[0068] see Figure 8 , is a flow chart of another intelligent control method for the drying end point of sintered fuel provided by this application. Such as Figure 7 As shown, the method includes:

[0069] 801. Acquire the current weight of the sintered fuel according to a preset period.

[0070] During the microwave drying process, the water content of the sintered fuel is constantly changing. The weight of the sintered fuel is continuously obtained according to the preset period, so as to grasp the drying condition of the sintered fuel in real time. The preset period can be determined according to the water content of the sintered fuel, the drying rate, and the total mass of a single microwave drying. In the embodiment of this application, there is no limitation on the determination and placement of the preset period. The preset period may be a fixed value or a variable value, which is not limited in this embodiment of the present application. Since during the drying p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com