Stripping-sticking aid mixed jet device for paper production

A technology of injection device and auxiliary agent, which is applied in papermaking, papermaking, textile and papermaking, etc., can solve problems such as low operation efficiency, pinholes, and damage to drying cylinders, so as to avoid manual operation, improve operation efficiency, and avoid negative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

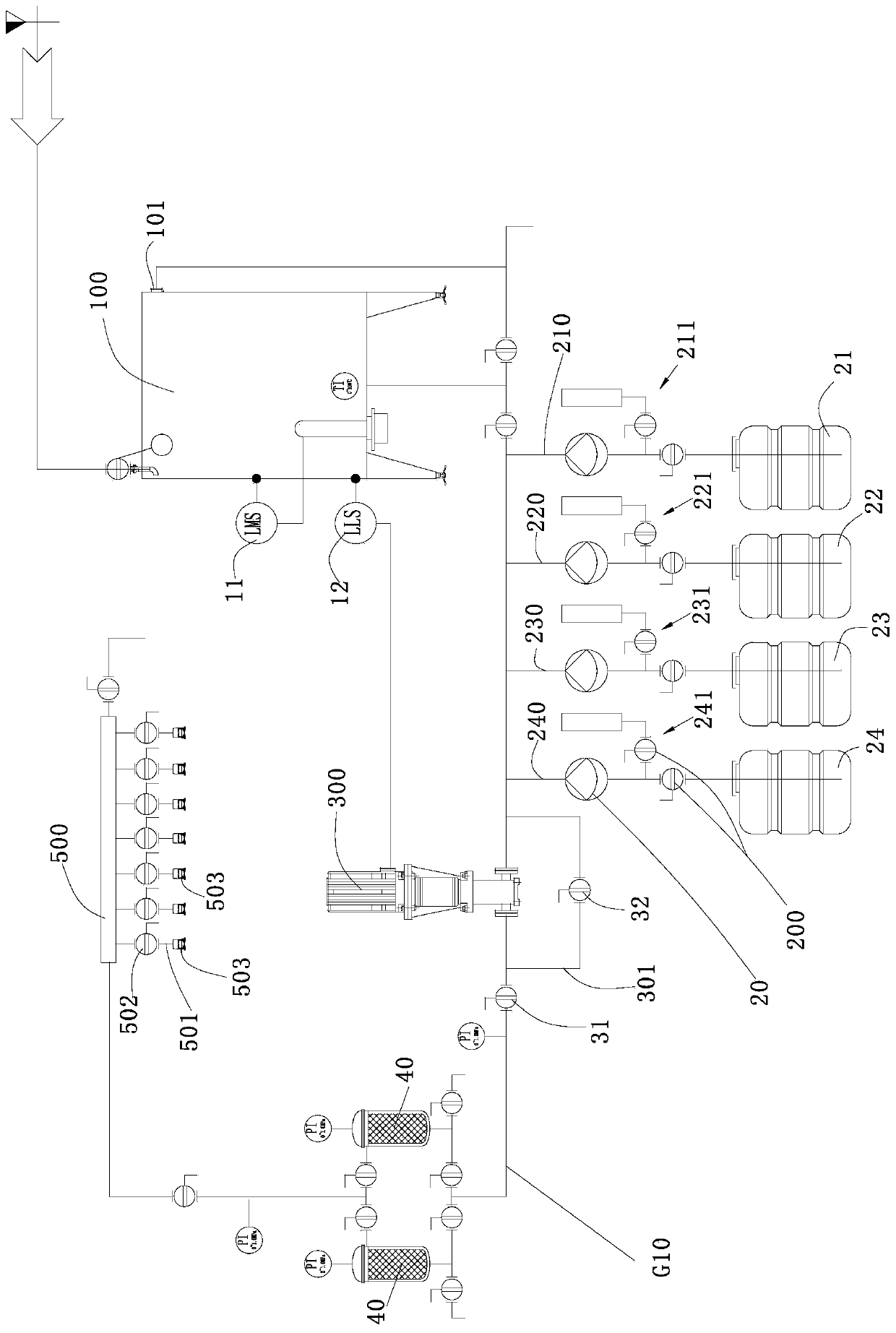

[0020] Such as figure 1 As shown, a stripping auxiliary agent mixing injection device for paper production, the stripping auxiliary agent includes a sticky agent, a stripping agent and a improver, and the mixing injection device is used to quantitatively and uniformly mix the sticky agent, release agent and improver After that, it is evenly added to the cylinder surface of the drying cylinder. The mixing and spraying device includes a main pipeline G10. The device also includes a first supply system for supplying warm water into the main pipeline G10, a second supply system for supplying peeling aids into the main pipeline G10, and a pumping system arranged on the main pipeline G10.

[0021] The connection between the second supply system and the main pipeline G10 is located downstream of the connection between the first supply syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com