Vertical ship lifting machine docking device and method

A technology of vertical ship lift and docking device, which is applied in vertical lifting ship machinery, ship lifting device, marine engineering and other directions, can solve the problems of affecting the navigation efficiency of ships, occupying the navigation time of ships, and insufficient docking, so as to improve docking efficiency. , the effect of simplifying the structure and reducing the scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030]The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0031] Example.

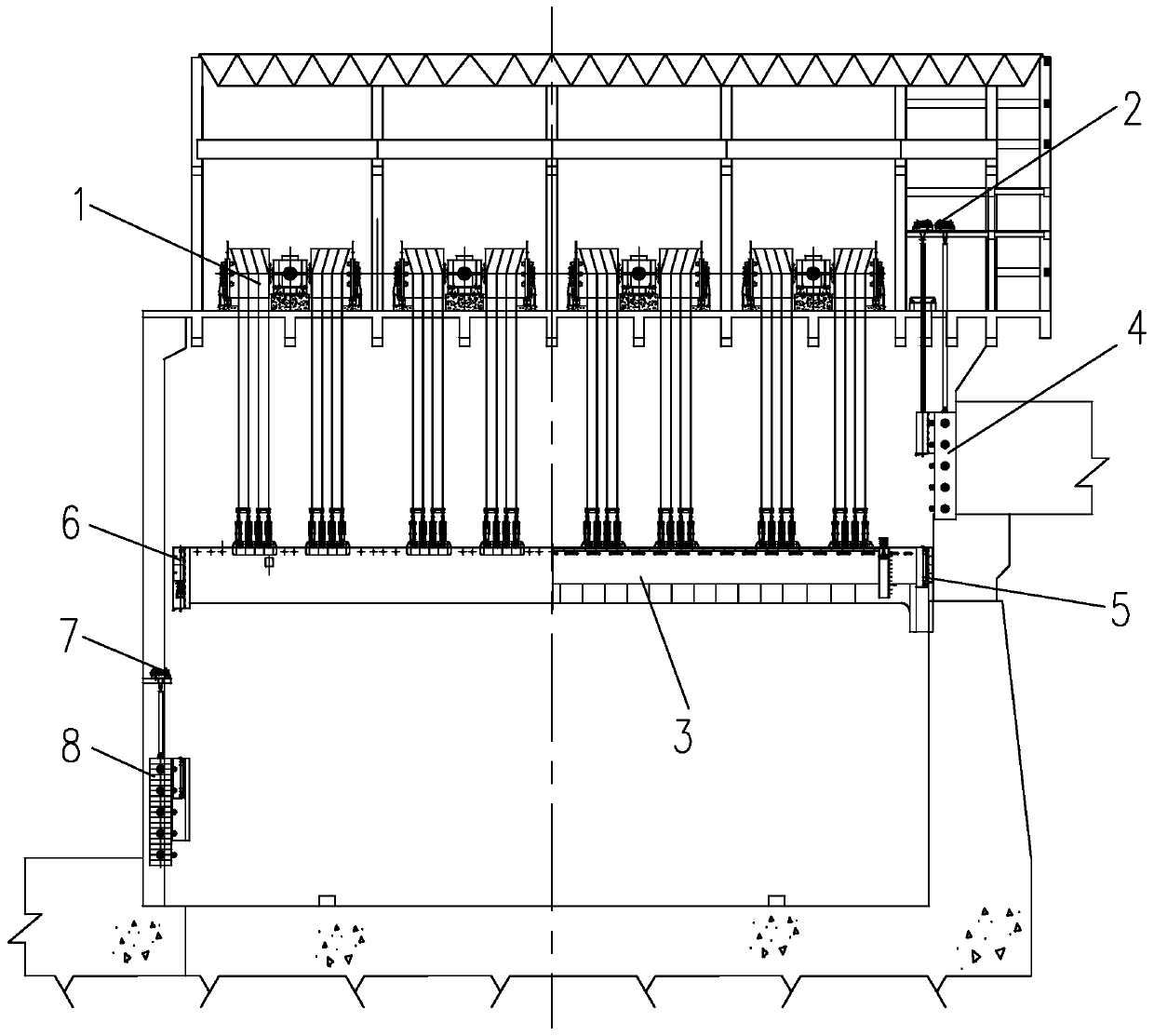

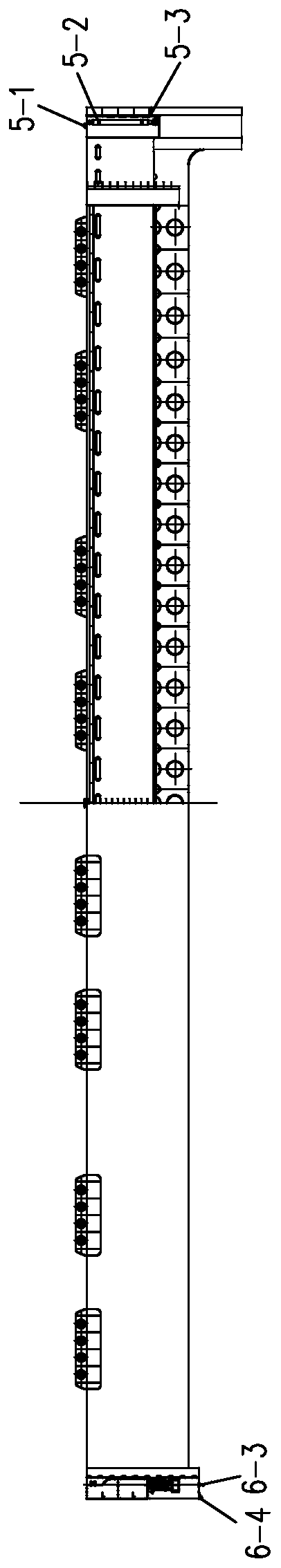

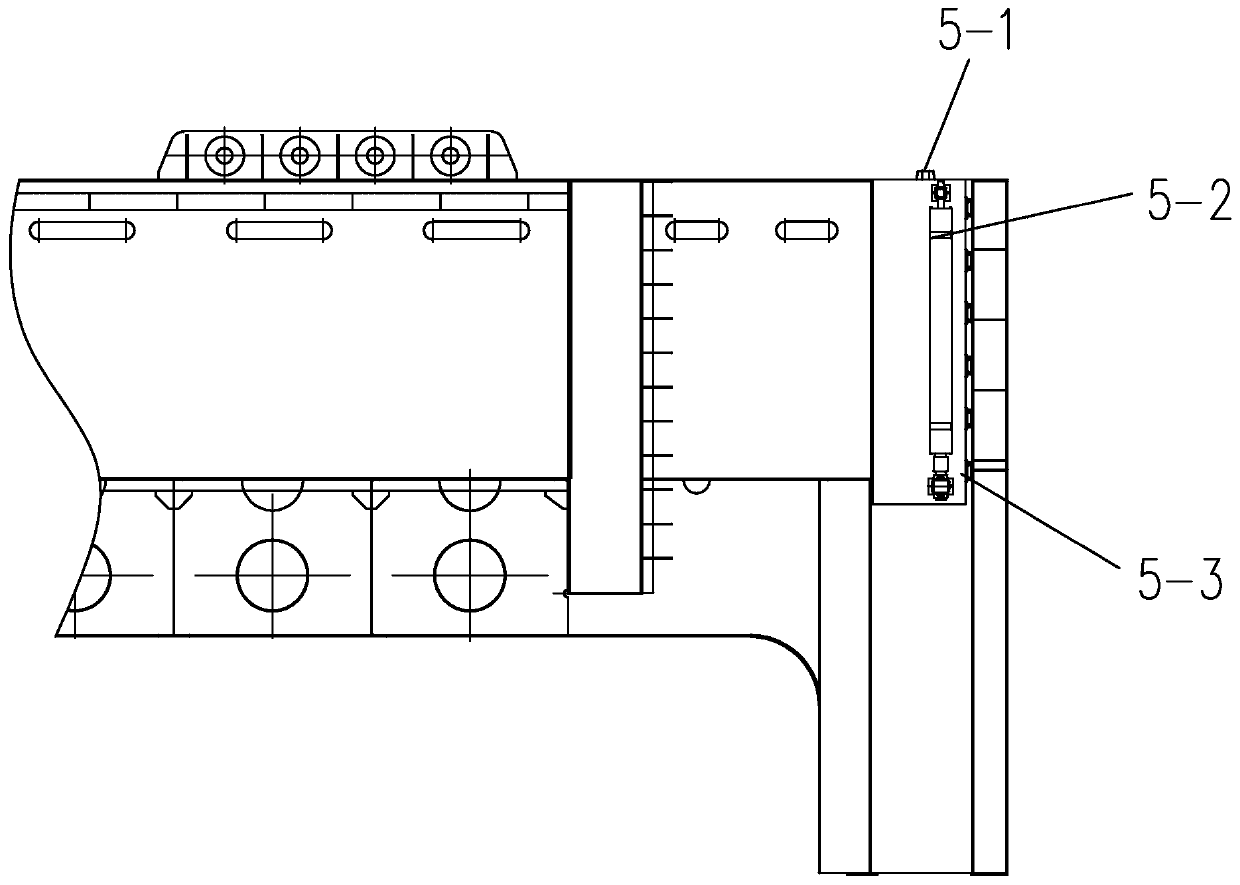

[0032] see Figure 1 to Figure 10 .

[0033] In this embodiment, a vertical ship lift docking device is provided, the docking device includes a main lifting system 1, a ship receiving compartment 3, an upstream working door 5 of the ship compartment, a downstream working door 6 of the ship compartment, an upper lock head 4 and a lower lock head 8. The main hoisting system 1 acts on the vessel 3 to provide power for the upper and lower movement of the vessel 3 . The upstream working door 5 of the ship compartment is installed on the upstream end of the compartment 3 , and the downstream working door 6 of the compartment is installed on the downstream end of the compartment 3 . The upper lock head...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com